Young

Edison

Young

Edison Young

Edison

Young

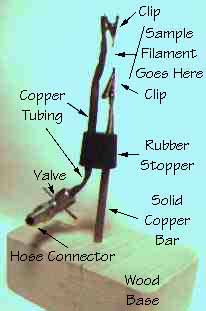

EdisonNote: This activity requires the use of a specially built piece of equipment. This equipment is illustrated and described below. The example piece I made for my students to use was soldered together. The equipment could just as well be held together with small machine screws or bolts. The equipment was constructed from 1/4" copper tubing, 1/4" solid copper bar, a small brass valve, a brass hose connector, a two hole rubber stopper, and two small alligator clips. No dimensions are critical. The equipment illustrated shows a little wear due to several years of student use. Things should still be clear though.

The custom equipment is illustrated at

the left. It consists of a wood base into which is plugged a solid copper

bar (rod). This solid copper bar goes through a rubber stopper and has a

small alligator clip soldered to its tapered end.

The custom equipment is illustrated at

the left. It consists of a wood base into which is plugged a solid copper

bar (rod). This solid copper bar goes through a rubber stopper and has a

small alligator clip soldered to its tapered end.

Through the other hole in the rubber stopper goes a length of copper tubing. At the top of this tubing is soldered another aligator clip. At the other end of the tubing is a small brass needle valve. A hose connector is fastened on to the brass valve.

A pyrex test tube fits over the whole thing and plugs onto the rubber stopper for an air tight fit.

Filaments to be tested are held between the two clips.

To the right is a close up of the two clips.

Once the filament sample is carefully clamped between the two clips, the whole thing is covered with the large test tube.

The air inside the test tube can be pumped out through the copper tubing so that the filaments may be tested under a partial vacuum. Stopcock grease may be used to seal any leaks around the stopper.

To the left is a close up of the brass

needle valve and hose connector. You will notice that the copper tubing

has been bent and crimped for clearance reasons. The tubing will still let

air flow.

To the left is a close up of the brass

needle valve and hose connector. You will notice that the copper tubing

has been bent and crimped for clearance reasons. The tubing will still let

air flow.

A vacuum pump is attached to the hose connector to evacuate the chamber around the filament.

Electrical leads are clipped to the solid copper bar and to the copper tubing so that current will flow through the filament sample.

Power supply: I use a variac as a power supply. You will find that 12 to 15 volts will work quite well. We have even used a 12 volt automobile battery charger (trickle type) with equal success. Your students might want to wear sun glasses when conducting their filament tests as the filaments can get rather bright.

Filament samples: My students have tested a wide variety of filament materials. I originally made the equipment to test the feasability of using ultrafine pencil leads (graphite) as a bulb filament. These are always available from the students and make a very bright light. Speaker wire which has been untwisted into its fine filaments makes a very good sample to test. I prefer to have the students come up with additional materials rather than making too many suggestions. Students may want to check references to duplicate Thomas Edison's carbonized thread filament. It must be emphasized that the samples need to be very fine.

What makes a good filament?: This is the heart of the Young Edison activity. This activity was created so that my students could:

I prefer to keep most of the lab activities for my students rather open ended to keep them thinking, involved, and working as a true team.