Making A Custom Form Tool

Copyright 2009 by James

P. Riser

For a special project that I wanted to make, I decided

to use a custom form tool for the machining. Basically form tools

are made in two types: dovetail or straight and circular. I chose

to use a circular type for ease of making.

The advantage of form tools is that they may be resharpened

repeatedly without altering the desired contours of the tool.

This web page documents how I made one form tool to

be used on my small turret lathe - shown below.

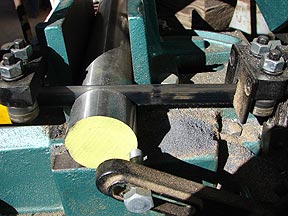

It all began with cutting off a length of O-1 tool

steel 2" in diameter.

It all began with cutting off a length of O-1 tool

steel 2" in diameter.

The blanks and

the collet used for turning.

The blank of 2" tool steel is first drilled then

bored to the required size for a tight fit.

The blanks and

the collet used for turning.

The blank of 2" tool steel is first drilled then

bored to the required size for a tight fit.

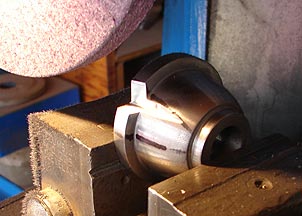

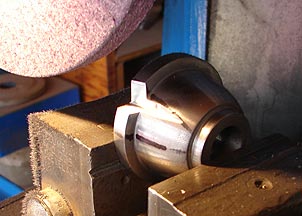

The blank was next

slid onto the tool holder bolt.

After mounting this assembly in my Sheldon lathe, the

form cutter was turned to shape.

The blank was next

slid onto the tool holder bolt.

After mounting this assembly in my Sheldon lathe, the

form cutter was turned to shape.

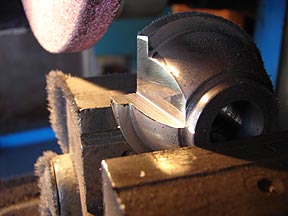

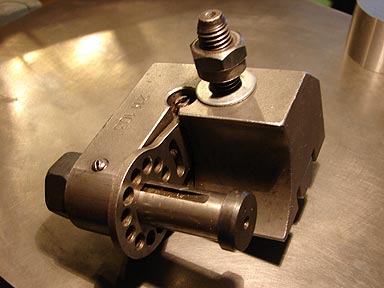

This is the tool after turning.

This is the tool after turning.

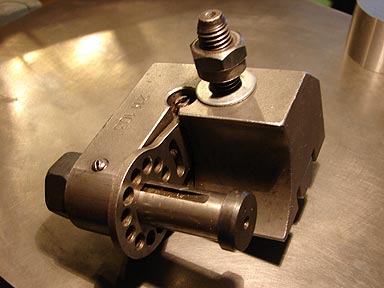

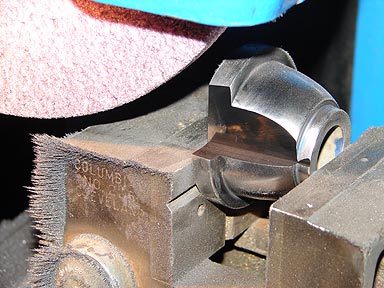

It gets held in

this form tool holder.

The holes are for positioning an index pin in the cutter.

The cutter was marked for drilling.

It gets held in

this form tool holder.

The holes are for positioning an index pin in the cutter.

The cutter was marked for drilling.

The hole for the index pin was drilled next.

The hole for the index pin was drilled next.

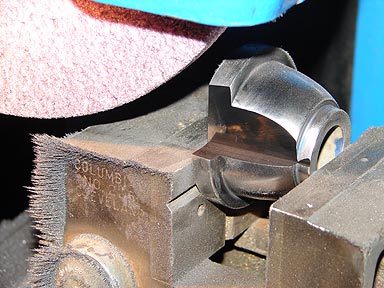

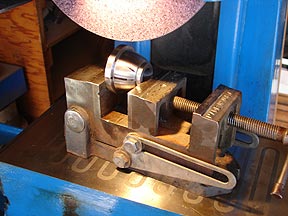

The cutter was

marked for grinding.

The grinding was done on my surface grinder.

The cutter was

marked for grinding.

The grinding was done on my surface grinder.

The heat treating

oven and tongs.

The heat treating

oven and tongs.

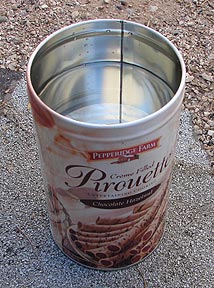

The oil for quenching.

The oil for quenching.

The toaster oven

preheated for tempering.

Heat treating was done in the oven with no control

of the atmosphere.

The toaster oven

preheated for tempering.

Heat treating was done in the oven with no control

of the atmosphere.

Oxide formed on

the cutting tool.

The oxide built up rather thick.

Oxide formed on

the cutting tool.

The oxide built up rather thick.

After soaking,

the cutter was quenched in the oil.

Most of the oxide flaked off as soon as the red hot

steel hit the oil.

After soaking,

the cutter was quenched in the oil.

Most of the oxide flaked off as soon as the red hot

steel hit the oil.

The cutter was next tempered in the toaster oven.

The cutter was next tempered in the toaster oven.

The tool after

tempering.

The residule scale was removed with a green scouring

pad.

The final grind (sharpening) was again done on the

surface grinder.

The tool after

tempering.

The residule scale was removed with a green scouring

pad.

The final grind (sharpening) was again done on the

surface grinder.

The finished tool after sharpening and cleaning.

The finished tool after sharpening and cleaning.

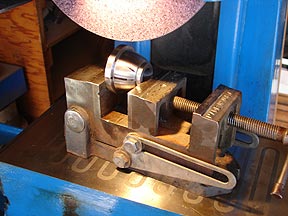

The tool ready

to mount (index pin has been installed).

The completed form cutter mounted on the holder.

The tool ready

to mount (index pin has been installed).

The completed form cutter mounted on the holder.

The cutter angle

is fine tuned with a screw driver.

The cutter angle

is fine tuned with a screw driver.

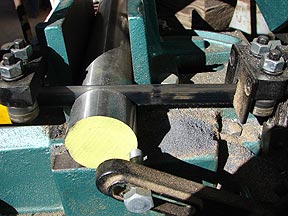

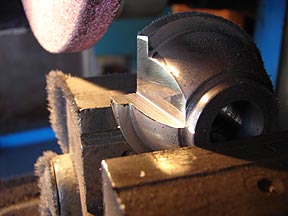

The cutter in use

on a 1" brass bar.

Cutting off on the turret lathe.

The cutter in use

on a 1" brass bar.

Cutting off on the turret lathe.

The last step was to engrave the finished weight.

The last step was to engrave the finished weight.

The completed weight.

The form tool size and shape allow making identical

weights as required.

The completed weight.

The form tool size and shape allow making identical

weights as required.

The blanks and

the collet used for turning.

The blanks and

the collet used for turning.

The blank was next

slid onto the tool holder bolt.

The blank was next

slid onto the tool holder bolt.

It gets held in

this form tool holder.

It gets held in

this form tool holder.

The cutter was

marked for grinding.

The cutter was

marked for grinding.

The heat treating

oven and tongs.

The heat treating

oven and tongs.

The oil for quenching.

The oil for quenching.

The toaster oven

preheated for tempering.

The toaster oven

preheated for tempering. Oxide formed on

the cutting tool.

Oxide formed on

the cutting tool.

After soaking,

the cutter was quenched in the oil.

After soaking,

the cutter was quenched in the oil.

The tool after

tempering.

The tool after

tempering.

The tool ready

to mount (index pin has been installed).

The tool ready

to mount (index pin has been installed).

The cutter angle

is fine tuned with a screw driver.

The cutter angle

is fine tuned with a screw driver. The cutter in use

on a 1" brass bar.

The cutter in use

on a 1" brass bar.

The completed weight.

The completed weight.