Making Tailstock Runners for a WW Lathe

Copyright 2010 by James

P. Riser

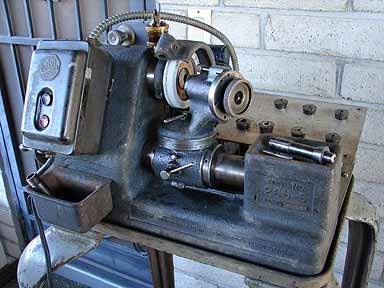

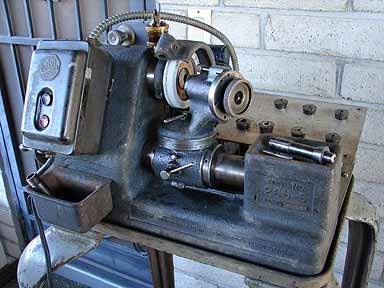

This is the standard

tailstock on one of my WW lathes.

The knob on the right end has been removed for cleaning.

The left end has an internal taper for holding male

or female dead centers.

A collet holding adaptor may also be plugged into this

taper.

Such lathes have a rather short bed and using the collet

holding adaptor takes up too much space.

So I decided to make a couple more useful tailstock

runners. This web page documents the techniques I used to make

new runners.

Hopefully this information will be useful to others.

This is the standard

tailstock on one of my WW lathes.

The knob on the right end has been removed for cleaning.

The left end has an internal taper for holding male

or female dead centers.

A collet holding adaptor may also be plugged into this

taper.

Such lathes have a rather short bed and using the collet

holding adaptor takes up too much space.

So I decided to make a couple more useful tailstock

runners. This web page documents the techniques I used to make

new runners.

Hopefully this information will be useful to others.

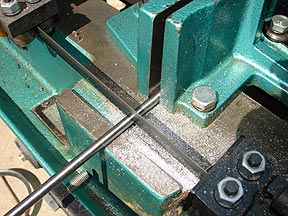

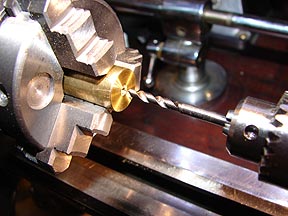

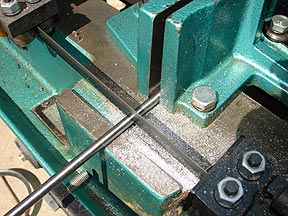

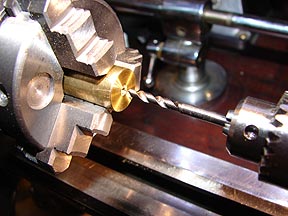

I started out by cutting a length of 5/16" air

hardening steel (A-2) for the runner.

W-1 (water hardening) or O-1 (oil hardening) steel

would also work.

I started out by cutting a length of 5/16" air

hardening steel (A-2) for the runner.

W-1 (water hardening) or O-1 (oil hardening) steel

would also work.

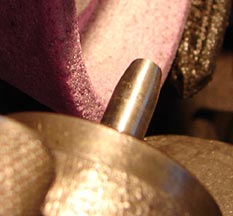

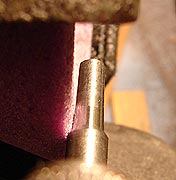

After cutting to

length, the end was ground flat and slightly tapered.

After cutting to

length, the end was ground flat and slightly tapered. I wanted to mount a new Jacobs Taper size 0 drill chuck

on the end of this runner for hand held drilling in the lathe.

I wanted to mount a new Jacobs Taper size 0 drill chuck

on the end of this runner for hand held drilling in the lathe.

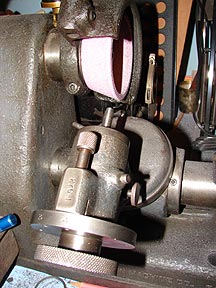

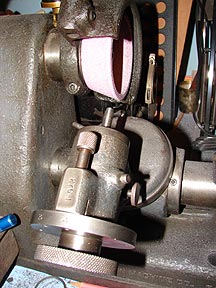

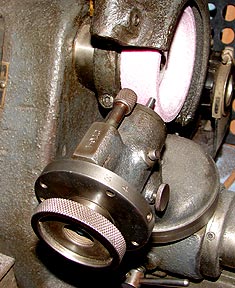

This tiny taper

was to be ground on a Gorton tool grinder.

This tiny taper

was to be ground on a Gorton tool grinder.  I looked up the proper angle and diameters for this

taper (1.4117 degrees). Small end is .2284". Large end is

.2500". Length of taper is .44".

It is impossible to just set the proper angle on my

grinder - so I chucked up a standard JT0 taper that I had and

set the angle from this.

I looked up the proper angle and diameters for this

taper (1.4117 degrees). Small end is .2284". Large end is

.2500". Length of taper is .44".

It is impossible to just set the proper angle on my

grinder - so I chucked up a standard JT0 taper that I had and

set the angle from this.

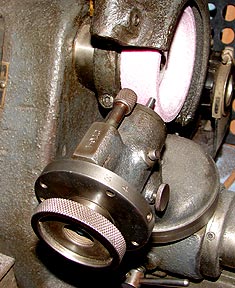

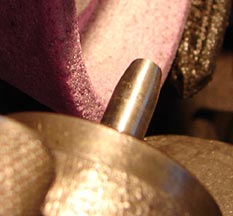

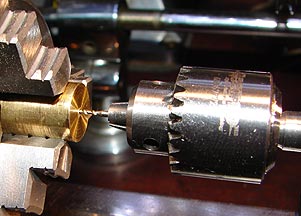

After dressing the wheel, the next step was to begin

the actual grinding. The previously rough ground taper saved time.

After dressing the wheel, the next step was to begin

the actual grinding. The previously rough ground taper saved time.

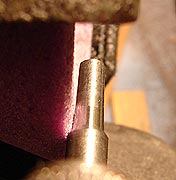

A series of small ground flats was made to gently form

the proper taper. Below is a sequence of the various stages of

grinding.

A series of small ground flats was made to gently form

the proper taper. Below is a sequence of the various stages of

grinding.

This is the final grind for the taper.

This is the final grind for the taper.  After test fitting to the new chuck, the length was

shortened as needed and a slight chamfer ground on the end.

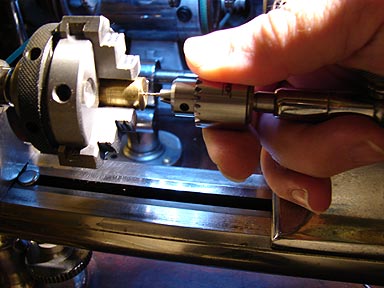

In use the runner slides within the tailstock and the

drill chuck is held by hand. This allows for very sensitive drilling

of small holes.

After test fitting to the new chuck, the length was

shortened as needed and a slight chamfer ground on the end.

In use the runner slides within the tailstock and the

drill chuck is held by hand. This allows for very sensitive drilling

of small holes.

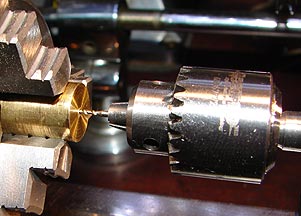

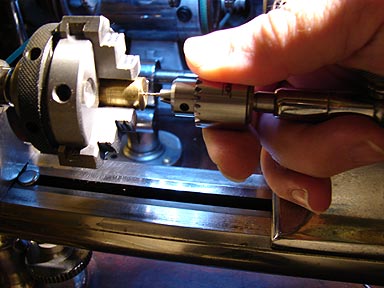

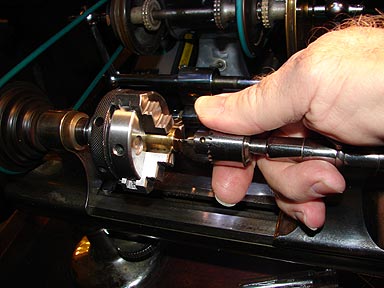

Here are the new

drill chuck and runner in use.

Here are the new

drill chuck and runner in use.

Drilling small

and larger holes.

Drilling small

and larger holes.  The completed setup.

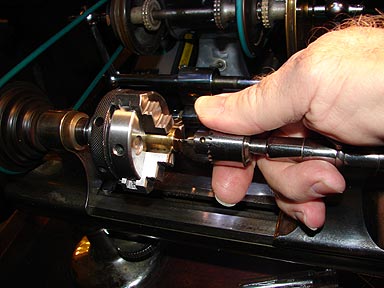

The completed setup.  In addition I wanted a new dead center runner. This

runner was to be locked into position in the tailstock as needed.

In addition I wanted a new dead center runner. This

runner was to be locked into position in the tailstock as needed.

The same grinder

was used, angle reset, and a series of flats ground.

These flats were then smoothed out into the new dead

center.

The same grinder

was used, angle reset, and a series of flats ground.

These flats were then smoothed out into the new dead

center.

The final dead

center runner.

The final dead

center runner.  I am very pleased with the functionality of these two

new runners.

Click here to return to

my machinery page.

I am very pleased with the functionality of these two

new runners.

Click here to return to

my machinery page.

This is the standard

tailstock on one of my WW lathes.

This is the standard

tailstock on one of my WW lathes.

After cutting to

length, the end was ground flat and slightly tapered.

After cutting to

length, the end was ground flat and slightly tapered.

This tiny taper

was to be ground on a Gorton tool grinder.

This tiny taper

was to be ground on a Gorton tool grinder.

Here are the new

drill chuck and runner in use.

Here are the new

drill chuck and runner in use.

Drilling small

and larger holes.

Drilling small

and larger holes.

The same grinder

was used, angle reset, and a series of flats ground.

The same grinder

was used, angle reset, and a series of flats ground. The final dead

center runner.

The final dead

center runner.