Creating the Vampire Master Casting Model

Copyright 2009 by James P. Riser

This page documents a few experiments done with the Roland

software during the creation of the final Vampire Model Casting

Master. This is for a product that I will be introducing in

the Fall of 2009. The machining was done with blue machinable

wax. The goal was to created a wax master for producing latex

molds for casting.

The master file and design work were created in Blender

by my younger son, Matt.

The master stl file is for a 360 degree vampire model. I will

only deal with a front view for my product requirements. Other

future products will deal with a full model.

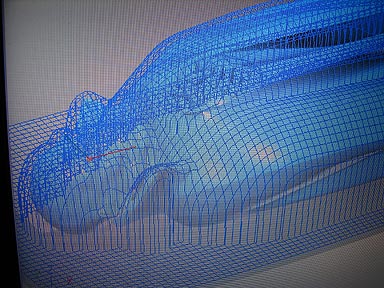

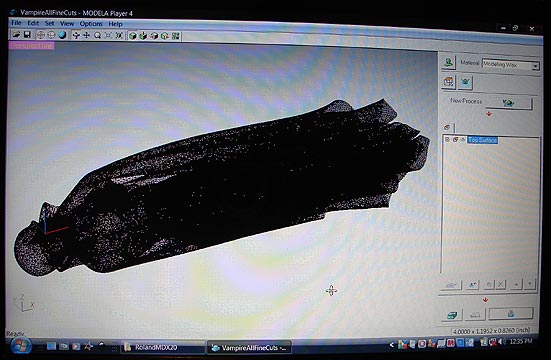

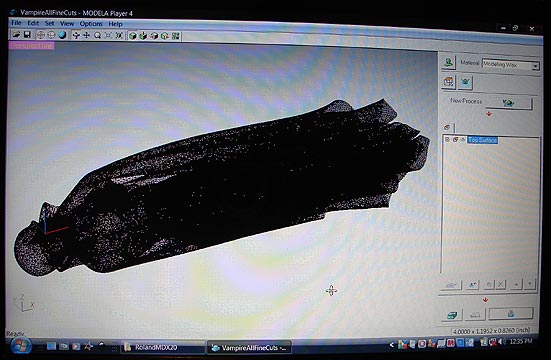

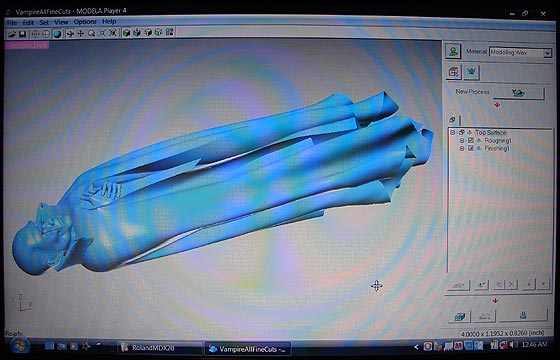

This is the master

file.

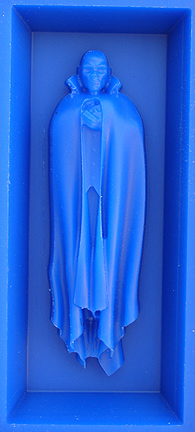

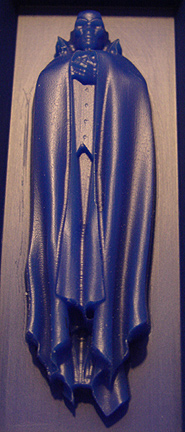

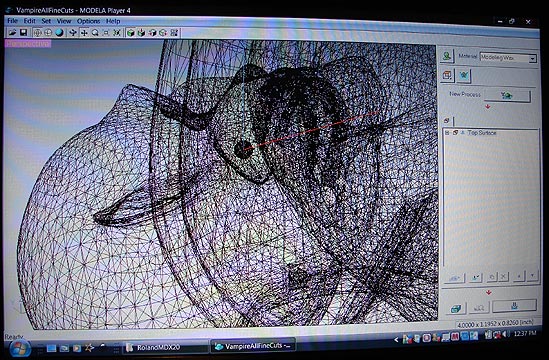

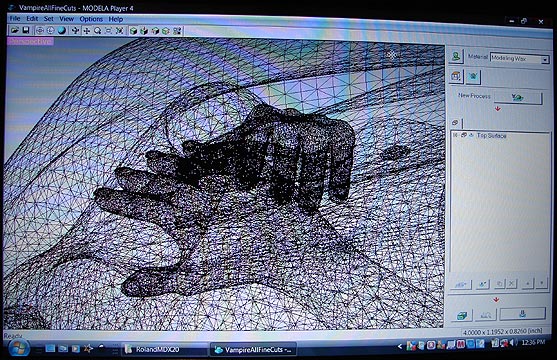

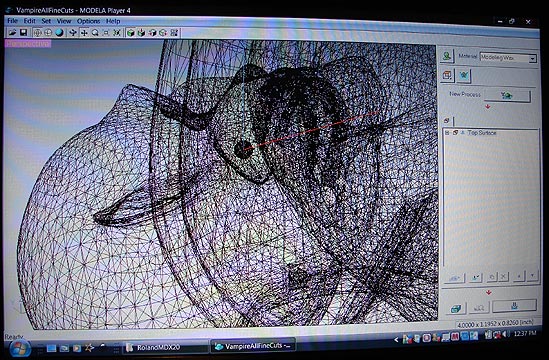

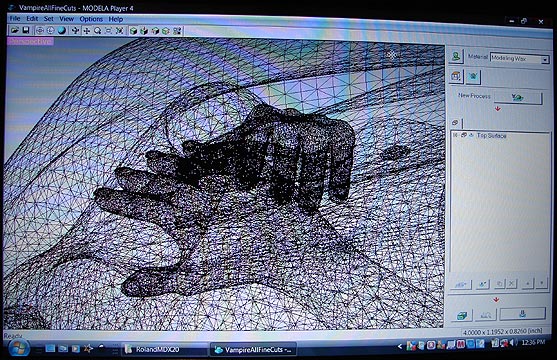

Here are a couple close up images of the detail.

This is the master

file.

Here are a couple close up images of the detail.

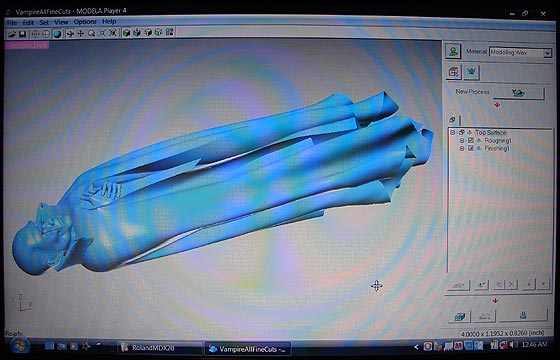

Here is the rendered file.

Here is the rendered file.

As you can see,

it is rather detailed.

The final model will only be 4" long by 1.25"

wide by .7" thick. It is hoped that too much detail will

not be lost at this small size.

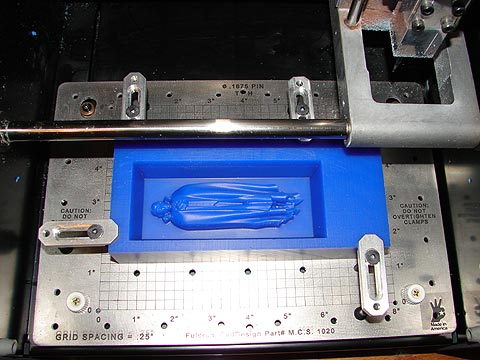

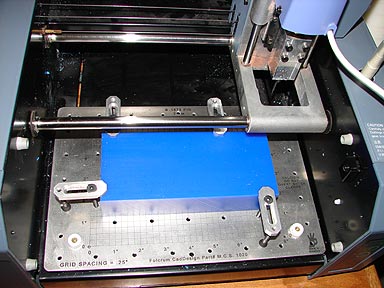

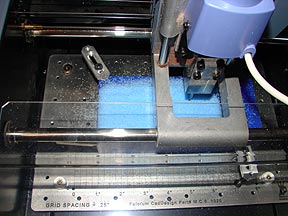

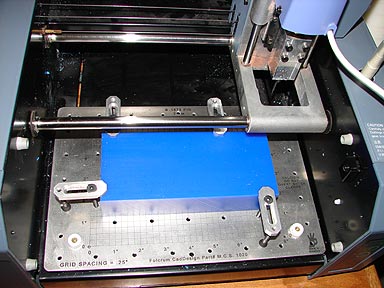

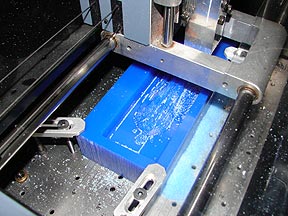

To begin, the 1.5" x 3" x 7" wax block

was clamped onto the machining table.

As you can see,

it is rather detailed.

The final model will only be 4" long by 1.25"

wide by .7" thick. It is hoped that too much detail will

not be lost at this small size.

To begin, the 1.5" x 3" x 7" wax block

was clamped onto the machining table.  Machining was begun using "contours" for

the surface as I wanted to see what the outcome would be.

Machining was begun using "contours" for

the surface as I wanted to see what the outcome would be.

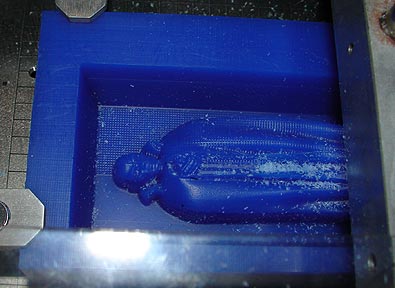

Things went fine until the very end of the roughing

cycle. At the scale desired, the model would be just under .9"

thick. I had set up the machine to go to this full depth. Even

though I had set up for sloped sides for tool clearance, the tool

rubbed too much on the verticle sides of the model causing a wax

build up on the cutter.

Things went fine until the very end of the roughing

cycle. At the scale desired, the model would be just under .9"

thick. I had set up the machine to go to this full depth. Even

though I had set up for sloped sides for tool clearance, the tool

rubbed too much on the verticle sides of the model causing a wax

build up on the cutter.

As if this was not bad enough, the machine started

to drill random holes in the wax. I believe this is due to the

software trying to deal with the back side of the model. Anyway,

one block of wax ruined; but much learned.

As if this was not bad enough, the machine started

to drill random holes in the wax. I believe this is due to the

software trying to deal with the back side of the model. Anyway,

one block of wax ruined; but much learned.

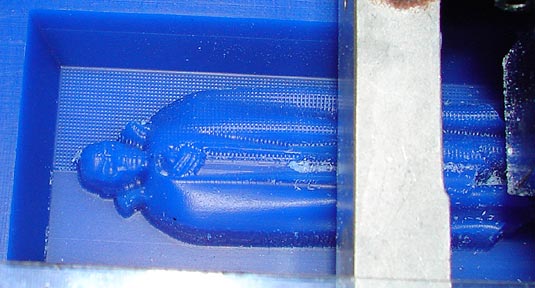

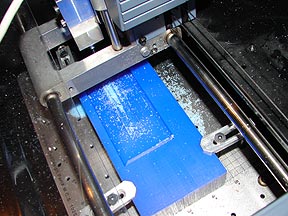

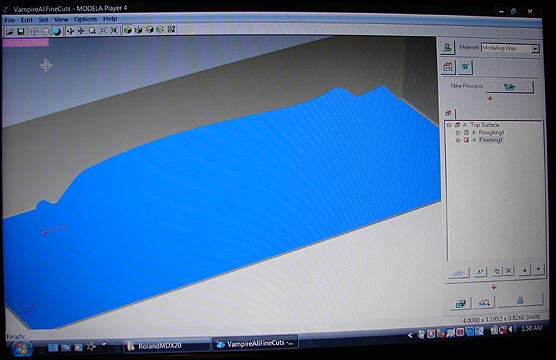

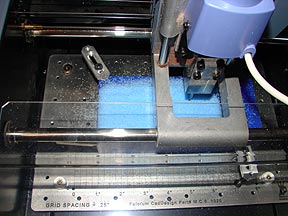

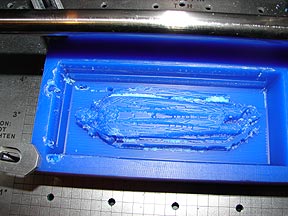

I next decided to only machine to a depth of .7"

which would be fine for my needs. Still testing the contour cutting,

I obtained this result for the roughing cuts.

This was not going to do what I really wanted. The

contours are way too obvious.

I next decided to only machine to a depth of .7"

which would be fine for my needs. Still testing the contour cutting,

I obtained this result for the roughing cuts.

This was not going to do what I really wanted. The

contours are way too obvious.

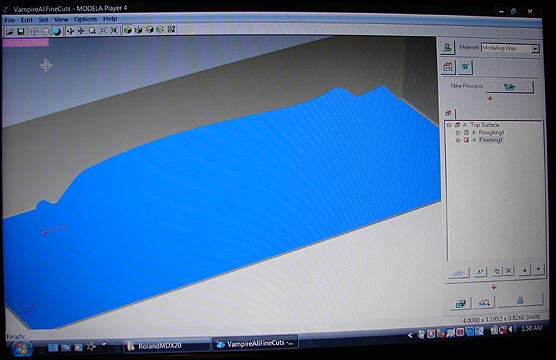

I reprogrammed to cut "x+y" for the passes

used during all cutting.

I reprogrammed to cut "x+y" for the passes

used during all cutting.

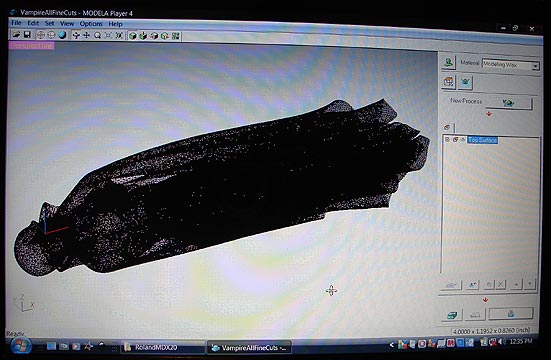

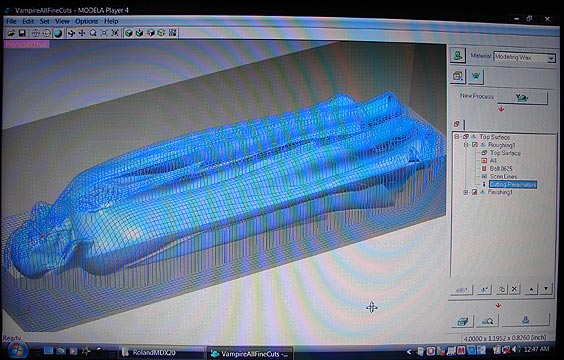

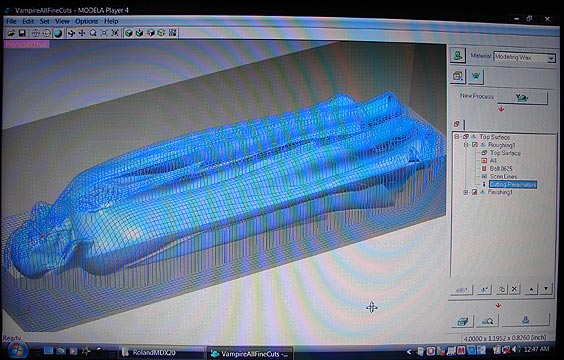

This tool path

was generated.

This would be much more like what I was shooting for.

This tool path

was generated.

This would be much more like what I was shooting for.

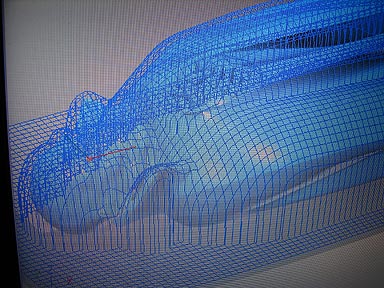

The finishing tool path was so dense that it looked

like this.

The finishing tool path was so dense that it looked

like this.

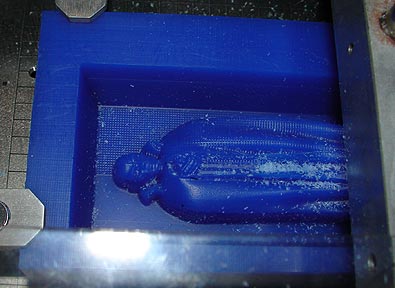

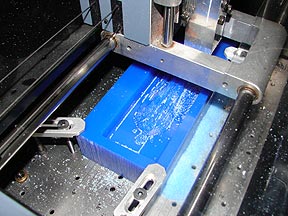

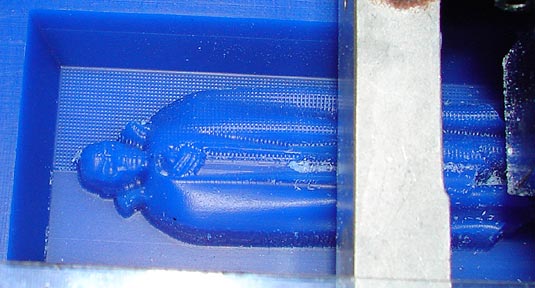

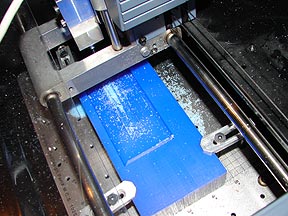

In the two images below you can see the textured cuts

made during roughing and the smoother finishing cuts in progress.

In the two images below you can see the textured cuts

made during roughing and the smoother finishing cuts in progress.

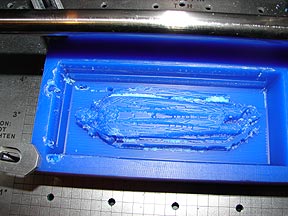

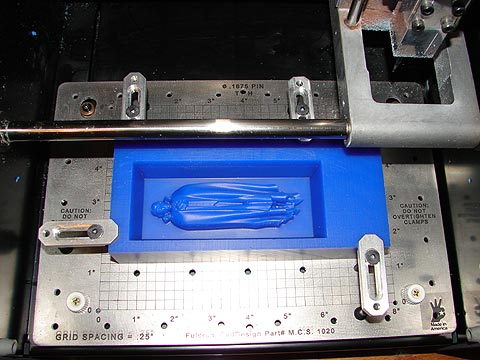

Here is the completed Vampire Master Casting Model

still in the Roland MDX-20.

Here is the completed Vampire Master Casting Model

still in the Roland MDX-20.

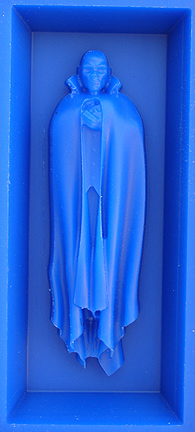

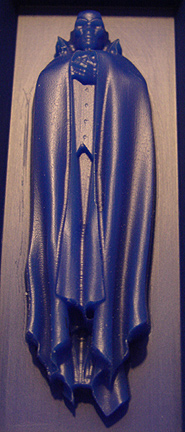

Some additional images to show the final detail . .

.

Some additional images to show the final detail . .

.

The Roland MDX-20 will certainly do what I wanted it

to do. I am very pleased with the detail obtained with the machine

and software.

Click

here to go to page 1

The Roland MDX-20 will certainly do what I wanted it

to do. I am very pleased with the detail obtained with the machine

and software.

Click

here to go to page 1

This is the master

file.

This is the master

file. This is the master

file.

This is the master

file.

As you can see,

it is rather detailed.

As you can see,

it is rather detailed.

This tool path

was generated.

This tool path

was generated.