My WW Lathe Setup

Copyright 2005 by James

P. Riser

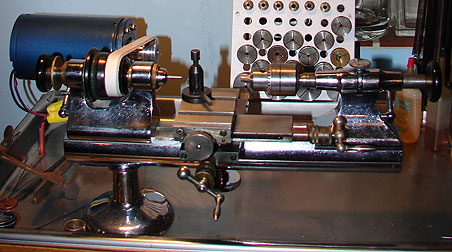

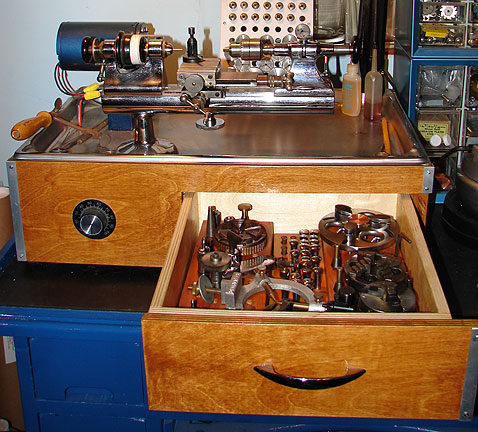

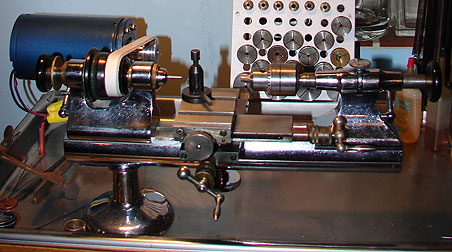

On this page is shown the setup I have made for my WW lathe.

Since everything was put together on a rather limited budget,

some pieces shown are not in mint condition. But all pieces displayed

here are in very good working condition. Any problems are merely

cosmetic. It is the best I have been able to assemble with the

funds available. This is the lathe I use for extremely fine machining

of parts for the items I manufacture. This is a working machine

not a display item.

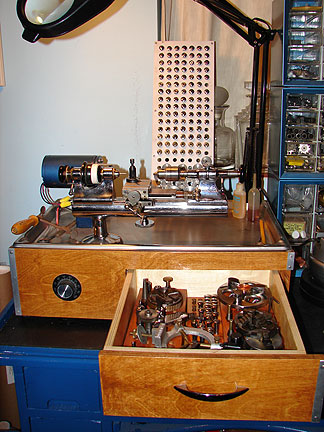

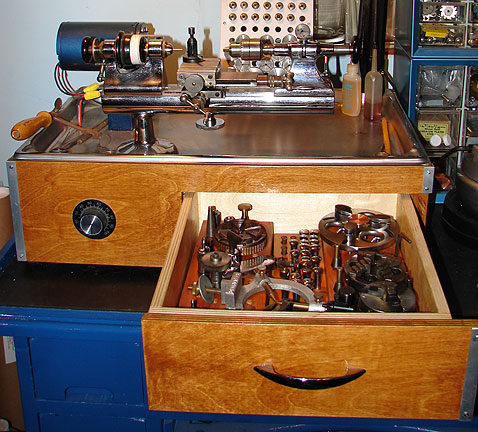

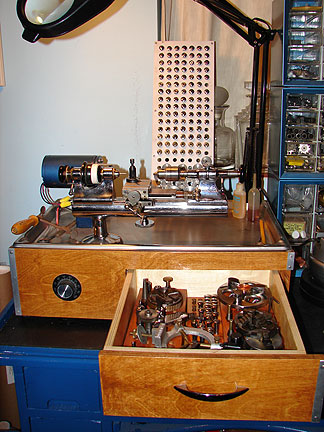

A stainless steel tray from a restaurant supply store

is the chip pan - to catch chips and oil.

The hardwood base was constructed to contain extra

parts as well as the motor speed control.

The whole unit may be picked up and moved as one piece,

if necessary.

The magnifier lamp plugs into a hole in the wood base

Collets are readily available in the aluminum collet

rack mounted on the back of the wood base.

A stainless steel tray from a restaurant supply store

is the chip pan - to catch chips and oil.

The hardwood base was constructed to contain extra

parts as well as the motor speed control.

The whole unit may be picked up and moved as one piece,

if necessary.

The magnifier lamp plugs into a hole in the wood base

Collets are readily available in the aluminum collet

rack mounted on the back of the wood base.

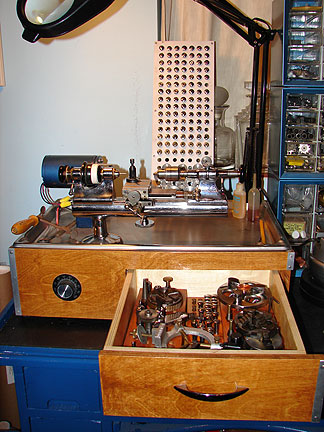

Most extra parts for the lathe are stored in the drawer.

A better view inside

the drawer...

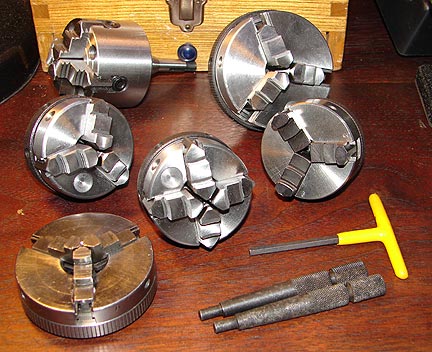

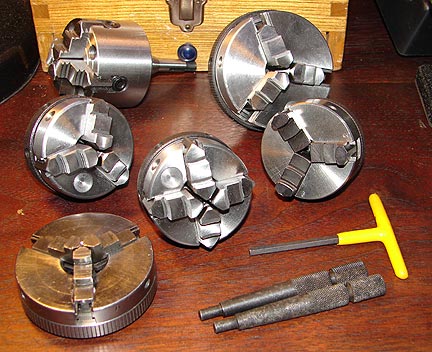

Here are a few of the "extras" required for

various jobs...

A better view inside

the drawer...

Here are a few of the "extras" required for

various jobs...

The wire chucks

or collets...

Bezel chucks...

The wire chucks

or collets...

Bezel chucks...

Other chucks...

Other chucks...

Tool rests and a

steady rest...

Tool rests and a

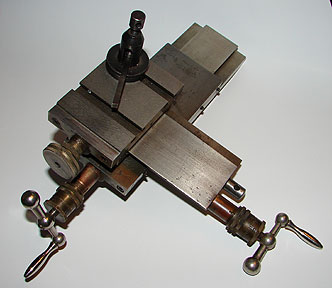

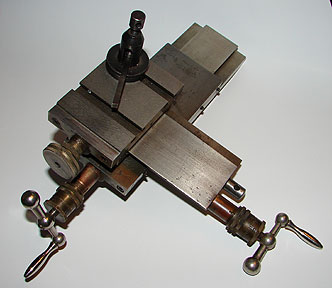

steady rest... Two stage cross slides...

Two stage cross slides...

A three stage cross

slide...

A three stage cross

slide...

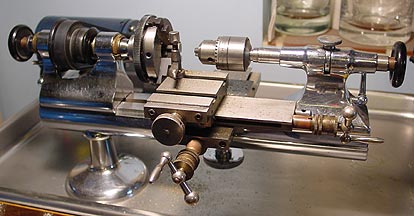

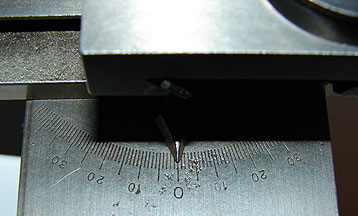

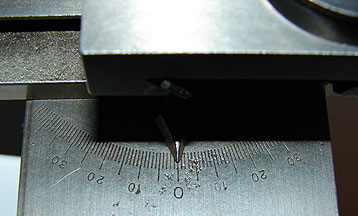

Angles are easily

set...

Angles are easily

set... The tailstock is a collet holding model.

The tailstock is a collet holding model.

WW colets are held

perfectly centered...

There are even male and female dead centers for special

work...

WW colets are held

perfectly centered...

There are even male and female dead centers for special

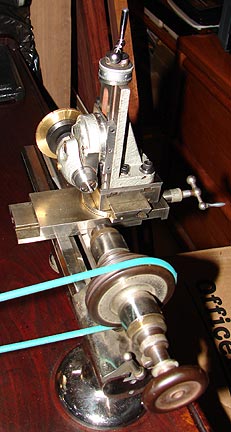

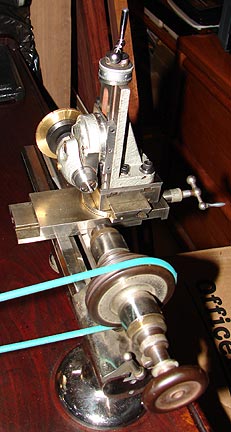

work...  The drive system for this lathe consists of a variable

speed DC motor, a controller, and a two step pulley option. This

allows two speed ranges - both variable.

The drive system for this lathe consists of a variable

speed DC motor, a controller, and a two step pulley option. This

allows two speed ranges - both variable.

The two steps of both the motor pulley and headstock

pulley may easily be seen here.

The drive belt is a synthetic leather belt.

The two steps of both the motor pulley and headstock

pulley may easily be seen here.

The drive belt is a synthetic leather belt.

I have mounted

the motor so that it may swing back and forth to adjust tension

on the belt.

As with most WW lathes, the headstock is set up for

indexing.

I have mounted

the motor so that it may swing back and forth to adjust tension

on the belt.

As with most WW lathes, the headstock is set up for

indexing.

I use these custom

made loupes to see what I am making.

I use these custom

made loupes to see what I am making.

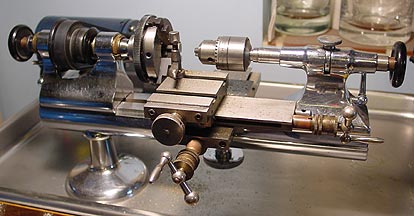

This is what the lathe looks like - ready for action.

A

second WW lathe is dedicated to drilling pinions and milling.

A

second WW lathe is dedicated to drilling pinions and milling.

Click

here to return to my machinery page.

Click

here to return to my machinery page.

A better view inside

the drawer...

A better view inside

the drawer... The wire chucks

or collets...

The wire chucks

or collets...

Tool rests and a

steady rest...

Tool rests and a

steady rest...

A three stage cross

slide...

A three stage cross

slide... Angles are easily

set...

Angles are easily

set...

WW colets are held

perfectly centered...

WW colets are held

perfectly centered...

I have mounted

the motor so that it may swing back and forth to adjust tension

on the belt.

I have mounted

the motor so that it may swing back and forth to adjust tension

on the belt.

I use these custom

made loupes to see what I am making.

I use these custom

made loupes to see what I am making.

A

second WW lathe is dedicated to drilling pinions and milling.

A

second WW lathe is dedicated to drilling pinions and milling.