A1 - beginning gear cutting

Copyright 2011 by James P. Riser

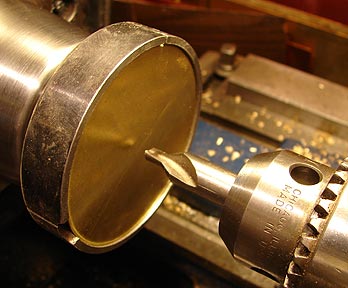

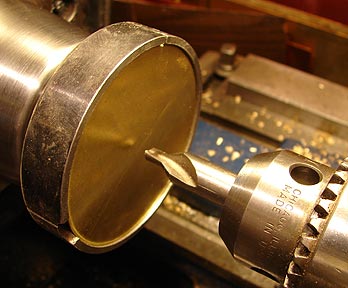

The largest gear in this project (2 3/4" diameter

blank) got mounted in a pot chuck for center drilling.

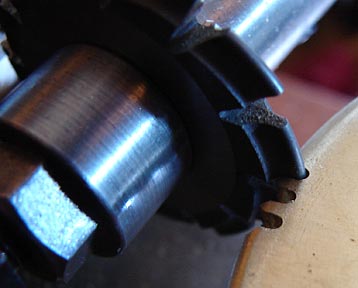

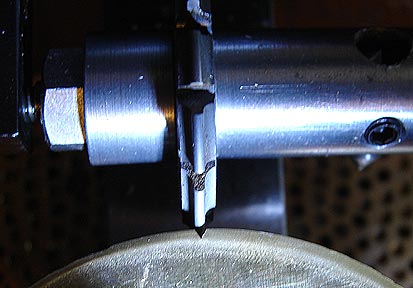

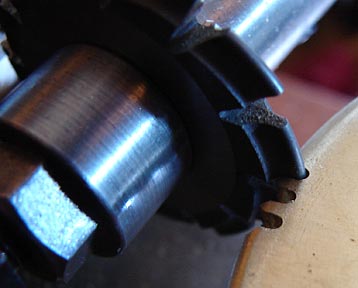

This hole drilling leaves a bur on the backside of

the blank which must be removed. I do this by gently touching

a center drill to the swiftly spinning brass disc. The bur pops

off as a ring (seen on the drill tip). After this, the blank is

ready to have teeth cut.

This hole drilling leaves a bur on the backside of

the blank which must be removed. I do this by gently touching

a center drill to the swiftly spinning brass disc. The bur pops

off as a ring (seen on the drill tip). After this, the blank is

ready to have teeth cut.

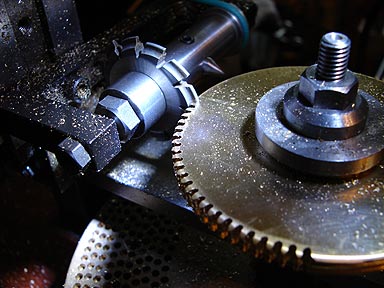

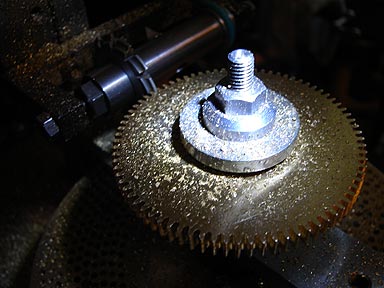

The brass blanks are next stacked (3 hign) for a quick

notching by the fly cutter.

This notch will come in handy later when centering

the actual wheel cutter.

The brass blanks are next stacked (3 hign) for a quick

notching by the fly cutter.

This notch will come in handy later when centering

the actual wheel cutter.

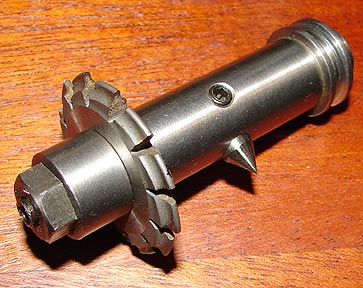

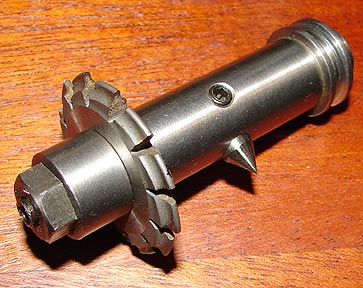

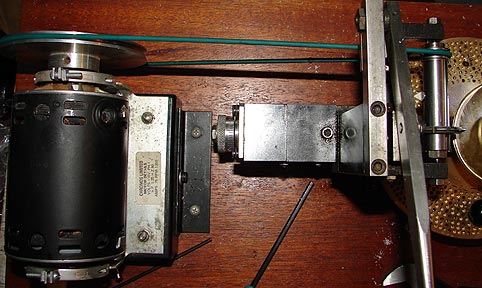

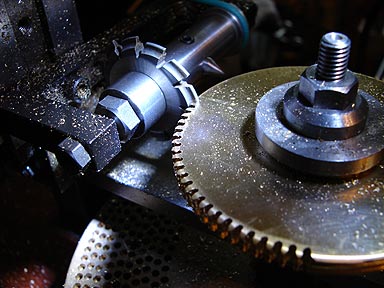

In order to mount the wheel cutter, the cutter spindle

must be removed from the cutting frame of the wheel engine.

In order to mount the wheel cutter, the cutter spindle

must be removed from the cutting frame of the wheel engine.

The left end is

loosened to accept the cutter.

The left end is

loosened to accept the cutter.  The correct wheel cutter for the module I need on this

project is mounted onto the cutter spindle. The 60 degree pivot

bearing for this spindle may be seen at the end of the axle.

The correct wheel cutter for the module I need on this

project is mounted onto the cutter spindle. The 60 degree pivot

bearing for this spindle may be seen at the end of the axle.

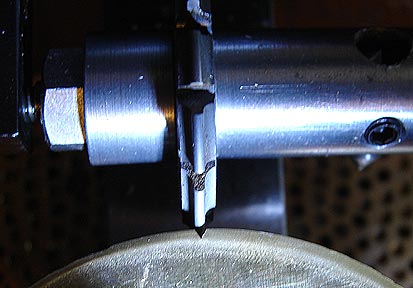

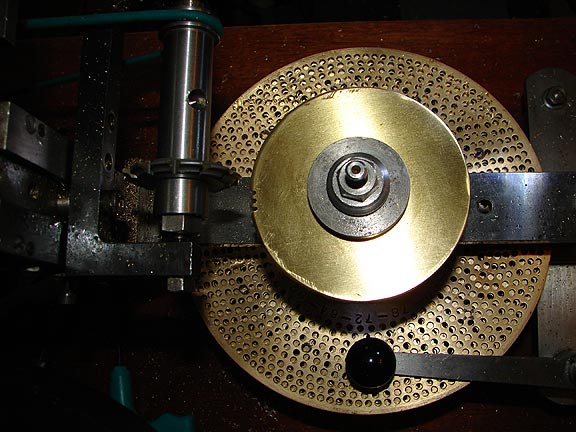

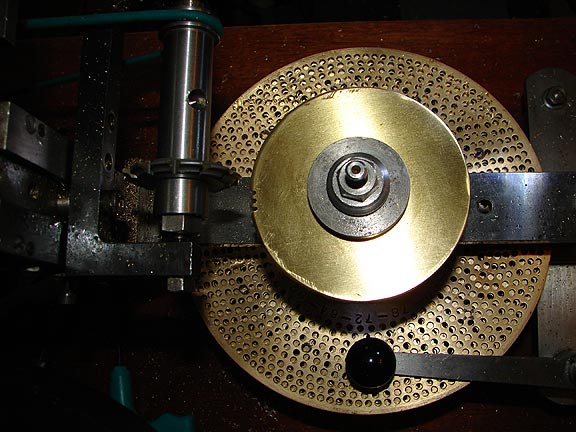

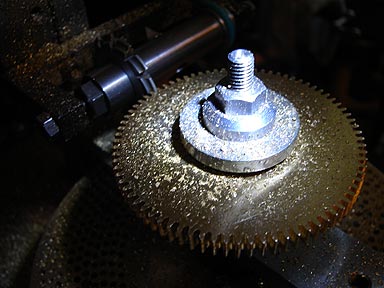

The previously made notch in the gear blank is used

to center the cutter with the axis of the wheel engine itself.

This is critical or the gear teeth will be crooked/off center.

To do this centering, the entire cutting frame is slid then locked

into position.

The previously made notch in the gear blank is used

to center the cutter with the axis of the wheel engine itself.

This is critical or the gear teeth will be crooked/off center.

To do this centering, the entire cutting frame is slid then locked

into position.

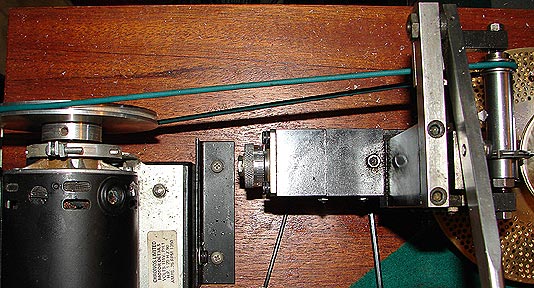

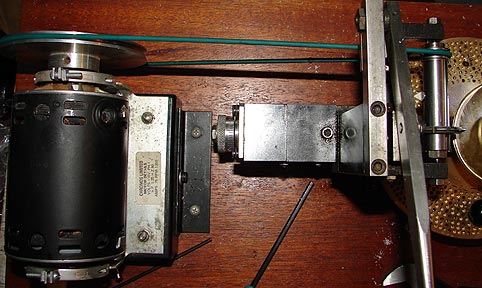

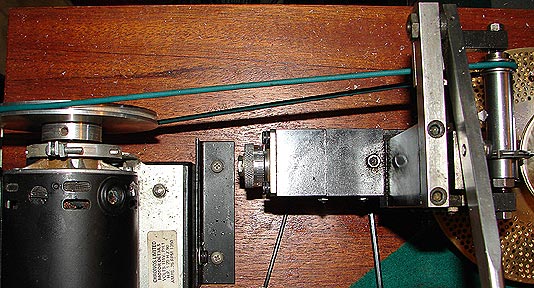

Adjusting the cutting frame causes the drive belt to

go out of alignment. If this is not fixed, the belt will jump

the pulleys. Fortunately the wheel engine was designed to slide

the motor back and forth to make this adjustment. The picture

on the right below shows the belt realigned.

Adjusting the cutting frame causes the drive belt to

go out of alignment. If this is not fixed, the belt will jump

the pulleys. Fortunately the wheel engine was designed to slide

the motor back and forth to make this adjustment. The picture

on the right below shows the belt realigned.

The cutting of the teeth can now be started. In cutting

these teeth the cutting frame with its spinning arbor/cutter may

be raised and lowered, as well as, moved in for deeper cuts.

The cutting of the teeth can now be started. In cutting

these teeth the cutting frame with its spinning arbor/cutter may

be raised and lowered, as well as, moved in for deeper cuts.

Here is a closeup of the teeth being cut into the three

.064" thick brass discs.

Here is a closeup of the teeth being cut into the three

.064" thick brass discs.  Below is a series of progress pictures of the gear

cutting.

Below is a series of progress pictures of the gear

cutting.

This is the shape of the gear teeth.

This is the shape of the gear teeth.

Here is another

view of the teeth.

800 teeth later ...

Here is another

view of the teeth.

800 teeth later ...  I

am making parts for several items.

The second wheel (smaller and with less teeth) was

cut in the same manner.

I

am making parts for several items.

The second wheel (smaller and with less teeth) was

cut in the same manner.

I needed to cut

75 teeth on this wheel and switched index plates.

The brass blanks were prepared as shown for the barrel

wheel.

I needed to cut

75 teeth on this wheel and switched index plates.

The brass blanks were prepared as shown for the barrel

wheel.  Cutting was then started.

Cutting was then started.

The completed second

wheels look like this.

Click here to go to page 1

Click here to go to page 3

The completed second

wheels look like this.

Click here to go to page 1

Click here to go to page 3

The left end is

loosened to accept the cutter.

The left end is

loosened to accept the cutter.

Here is another

view of the teeth.

Here is another

view of the teeth. I

am making parts for several items.

I

am making parts for several items. I needed to cut

75 teeth on this wheel and switched index plates.

I needed to cut

75 teeth on this wheel and switched index plates.

The completed second

wheels look like this.

The completed second

wheels look like this.