Engraving a Copper Cup

Copyright 2010 by James P. Riser

Note: This is a sample from an ebook that I

am currently creating.

In this publication I shall explain in detail the techniques

I use to engrave metal cups. The process will feature hand engraving.

CNC work is avoided due to the "mechanical look" of

the cuts done by that technique. Only hand work can create the

desired bright cuts identified with quality engravings.

In order to engrave the metal an assortment of gravers

is required. The number and types of gravers required depends

upon the type of work to be done. Here are an assortment of hand

gravers that I like for such work.

In addition to the mounted gravers shown above, I have

a large selection of unmounted gravers for special effects or

detail work. These are stored in a maple block. I either mount

these in mushroom handles as shown above or in my pneumatic hand

pieces - to be shown later.

In addition to the mounted gravers shown above, I have

a large selection of unmounted gravers for special effects or

detail work. These are stored in a maple block. I either mount

these in mushroom handles as shown above or in my pneumatic hand

pieces - to be shown later.

And a close up of these gravers ...

And a close up of these gravers ...

The next problem to be considered is how to hold the

cup to be engraved. I prefer to use an engravers block or vise.

Shown below are several from my shop. The first is from about

1850 and still works perfectly.

The next problem to be considered is how to hold the

cup to be engraved. I prefer to use an engravers block or vise.

Shown below are several from my shop. The first is from about

1850 and still works perfectly.

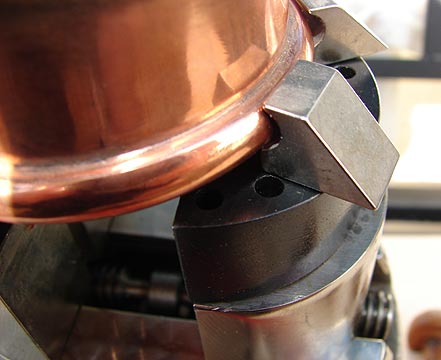

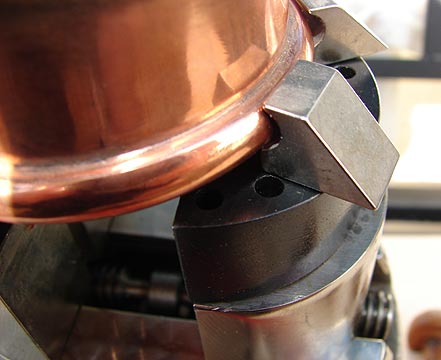

The second block is from the same era or slightly earlier.

It also works as well as when new. Below it can be seen gripping

a copper cup for engraving the bottom.

The second block is from the same era or slightly earlier.

It also works as well as when new. Below it can be seen gripping

a copper cup for engraving the bottom.

All of the engravers blocks feature top jaws with an

arrangement of small holes. These holes are to hold various attachments

to aid in gripping oddly shaped items.

All of the engravers blocks feature top jaws with an

arrangement of small holes. These holes are to hold various attachments

to aid in gripping oddly shaped items.

Here is a typical attachment set for an engravers block.

Here is a typical attachment set for an engravers block.

A block and its

attachment set ...

Here are cup holder jaws securing a cup for engraving

the bottom. Other attachment jaws are used when engraving the

sides of the cup.

A block and its

attachment set ...

Here are cup holder jaws securing a cup for engraving

the bottom. Other attachment jaws are used when engraving the

sides of the cup.

This a new style very heavy duty engravers block for

use with pneumatic tools. The top jaws have been removed for holding

a small metal plate to be engraved.

This a new style very heavy duty engravers block for

use with pneumatic tools. The top jaws have been removed for holding

a small metal plate to be engraved.

In order to do quality engravings the engraver must

be able to accurately sharpen the gravers. Shown here is a traditional

style graver sharpener. It is used with varying grits of stones

- ending with an Arkansas stone for the final polishing grind.

You can see that the angles may be easily adjusted.

In order to do quality engravings the engraver must

be able to accurately sharpen the gravers. Shown here is a traditional

style graver sharpener. It is used with varying grits of stones

- ending with an Arkansas stone for the final polishing grind.

You can see that the angles may be easily adjusted.

A newer style of graver holder for sharpening on a

diamond hone is shown below. This is adequate for many needs.

A newer style of graver holder for sharpening on a

diamond hone is shown below. This is adequate for many needs.

The ultimate graver holder is shown below. All angles

may be adjusted with ease. This is to be used with a powered diamond

home.

The ultimate graver holder is shown below. All angles

may be adjusted with ease. This is to be used with a powered diamond

home.

More to come - some day (possibly only in the finished

publication).

More to come - some day (possibly only in the finished

publication).

A block and its

attachment set ...

A block and its

attachment set ...