Adding a Crosshair

to the

Student Grade Premiere Microscope

Copyright 2002 by James P. Riser

I purchased

this student grade 20x microscope to assist in indexing cutting

tools on my EMCO Compact 5 PC Lathe. The microscope is inexpensive

and once a crosshair is added will serve this purpose quite well.

Premiere Microscopes does not supply a crosshair for this scope

so one must be fabricated.

A crosshair must be made from

an extremely thin filament which is also very strong. In the past

the web from a black widow spider has been used for this task.

Since I live in Tucson, Arizona, finding an accommodating black

widow would be easy. Before I went looking for the spider and

her web, I remembered that I had a spool of Kevlar thread on hand

and figured that I could unravel it to get a single fine filament.

Shown at the right is a short length of this thread after unravelling.

You can see the individual fibers.

I purchased

this student grade 20x microscope to assist in indexing cutting

tools on my EMCO Compact 5 PC Lathe. The microscope is inexpensive

and once a crosshair is added will serve this purpose quite well.

Premiere Microscopes does not supply a crosshair for this scope

so one must be fabricated.

A crosshair must be made from

an extremely thin filament which is also very strong. In the past

the web from a black widow spider has been used for this task.

Since I live in Tucson, Arizona, finding an accommodating black

widow would be easy. Before I went looking for the spider and

her web, I remembered that I had a spool of Kevlar thread on hand

and figured that I could unravel it to get a single fine filament.

Shown at the right is a short length of this thread after unravelling.

You can see the individual fibers.

The easily removable eyepiece

has the standard recess built into it. It is into the bottom of

this recess that the crosshair must be placed. On a better grade

of microscope the eyepiece tube will be threaded to adjust the

lens spacing and to add the crosshair fitting. If the crosshair

is not in the correct focal plane, it will be out of focus.

The easily removable eyepiece

has the standard recess built into it. It is into the bottom of

this recess that the crosshair must be placed. On a better grade

of microscope the eyepiece tube will be threaded to adjust the

lens spacing and to add the crosshair fitting. If the crosshair

is not in the correct focal plane, it will be out of focus.

Before machining the crosshair

fitting, I decided to do a quick and dirty test of the Kevlar

filament and of the assumed focal plane.

In the image at the right you

can see a single filament stretched across the bottom of the recess.

It is temporarily held in position with tape. When I looked through

the eyepiece, I could see that everything was in focus and would,

indeed, work as desired.

The next step was to machine

a mounting ring for the crosshair.

Before machining the crosshair

fitting, I decided to do a quick and dirty test of the Kevlar

filament and of the assumed focal plane.

In the image at the right you

can see a single filament stretched across the bottom of the recess.

It is temporarily held in position with tape. When I looked through

the eyepiece, I could see that everything was in focus and would,

indeed, work as desired.

The next step was to machine

a mounting ring for the crosshair.

I

chose to machine the plastic fitting on my watchmaker's lathe.

The setup is shown here.

I

chose to machine the plastic fitting on my watchmaker's lathe.

The setup is shown here.

A 3/8" long section of heavy

walled PVC plastic tubing was the basis for the fitting. Here

you can see it mounted in the lathe chuck ready to have the cut

end squared off.

A 3/8" long section of heavy

walled PVC plastic tubing was the basis for the fitting. Here

you can see it mounted in the lathe chuck ready to have the cut

end squared off.

After squaring the end, the slide

rest was rotated to zero so that a square shoulder could be cut

on the plastic.

After squaring the end, the slide

rest was rotated to zero so that a square shoulder could be cut

on the plastic.

The worst part of this whole

project is the fine strands of plastic which are removed. They

static cling to everything!

The worst part of this whole

project is the fine strands of plastic which are removed. They

static cling to everything!

The

shoulder should be square like this.

It is a good idea to make certain

that the turned shoulder fits the eyepiece tube.

The

shoulder should be square like this.

It is a good idea to make certain

that the turned shoulder fits the eyepiece tube.

I next reversed the fitting in

the chuck to machine the other end so that it would align properly

with the end of the eyepiece tube.

Shown here are the finished fitting

and an extra piece of PVC tubing.

I next reversed the fitting in

the chuck to machine the other end so that it would align properly

with the end of the eyepiece tube.

Shown here are the finished fitting

and an extra piece of PVC tubing.

The next step was to add the

Kevlar filaments to this fitting. Things get pretty difficult

to see during this process and the microscope can be used to make

the job easier. I covered the black plexiglass microscope base

plate with thin plastic wrap to protect it while attaching the

filaments. Super glue was used as the glue for attaching the Kevlar

strands to the plastic ring. You do not want to get this on the

black plexiglass!

These images illusttrate the

attaching of the crosshair filaments.

The fibers were held stretched

until the glue set.

Instead of Kevlar fibers, single

strands from nylon panty hose could be used.

These images illusttrate the

attaching of the crosshair filaments.

The fibers were held stretched

until the glue set.

Instead of Kevlar fibers, single

strands from nylon panty hose could be used.

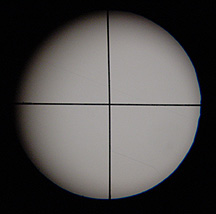

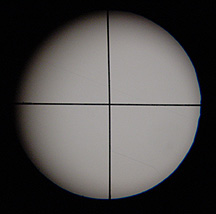

Below are images showing the

modified microscope in use.

The crosshairs.

Indexing

a tool.

Indexing

a tool.

I mounted the whole microscope

assembly onto a magnetic indicator base to temporarily attach

it to the lathe bed while indexing tools on my EMCO lathe.

The magnetic base came from Harbor

Freight and the post was slightly smaller that the original microscope

post. A brass bushing was made to take up the "slack".

This bushing was made from three

different diameters of thin walled brass tubing as found in hobby

and hardware stores.

The tubing lengths were soldered

together. Notice that the largest diameter tubing forms a collar

on the bushing.

The wall of the bushing was slotted

in four places to allow it to collapse as the microscope clamping

knob is tightened.

To do this job correctly, I should

have machined the bushing from solid brass bar and slotted it

on my milling machine rather than free hand.

I was lazy today! It works.

This bushing was made from three

different diameters of thin walled brass tubing as found in hobby

and hardware stores.

The tubing lengths were soldered

together. Notice that the largest diameter tubing forms a collar

on the bushing.

The wall of the bushing was slotted

in four places to allow it to collapse as the microscope clamping

knob is tightened.

To do this job correctly, I should

have machined the bushing from solid brass bar and slotted it

on my milling machine rather than free hand.

I was lazy today! It works.

The

bushing was then slid onto the magnetic base post - collar down.

The scope was slid down onto

the post around this bushing and the knob tightened.

The

bushing was then slid onto the magnetic base post - collar down.

The scope was slid down onto

the post around this bushing and the knob tightened.

Here

is the complete setup - ready to mount on the lathe bed.

I hope this web page will help

others who are trying to machine metal and plastics on a limited

budget. Enjoy.

Here

is the complete setup - ready to mount on the lathe bed.

I hope this web page will help

others who are trying to machine metal and plastics on a limited

budget. Enjoy.

I purchased

this student grade 20x microscope to assist in indexing cutting

tools on my EMCO Compact 5 PC Lathe. The microscope is inexpensive

and once a crosshair is added will serve this purpose quite well.

Premiere Microscopes does not supply a crosshair for this scope

so one must be fabricated.

I purchased

this student grade 20x microscope to assist in indexing cutting

tools on my EMCO Compact 5 PC Lathe. The microscope is inexpensive

and once a crosshair is added will serve this purpose quite well.

Premiere Microscopes does not supply a crosshair for this scope

so one must be fabricated.

I

chose to machine the plastic fitting on my watchmaker's lathe.

The setup is shown here.

I

chose to machine the plastic fitting on my watchmaker's lathe.

The setup is shown here.

The

shoulder should be square like this.

The

shoulder should be square like this.

Indexing

a tool.

Indexing

a tool.

The

bushing was then slid onto the magnetic base post - collar down.

The

bushing was then slid onto the magnetic base post - collar down.

Here

is the complete setup - ready to mount on the lathe bed.

Here

is the complete setup - ready to mount on the lathe bed.