Sewing Machines in the Shop

Copyright 2005 by James

P. Riser

With the variety of items that I manufacture for magicians

around the world, I often need to sew portions of the products.

I also keep several of my metal working machines outside and like

to make weather proof coverings for these machines to keep them

clean and dry. This requires sewing.

Shown on this short web page are some of the sewing

machines I use in my business:

This Tippmann "Boss"

is for leather (up to 3/4" thick) and nylon webbing. It is

hand powered.

Since I took the "Boss" picture, I have added

a thread storage shelf below the bench.

This Tippmann "Boss"

is for leather (up to 3/4" thick) and nylon webbing. It is

hand powered.

Since I took the "Boss" picture, I have added

a thread storage shelf below the bench.

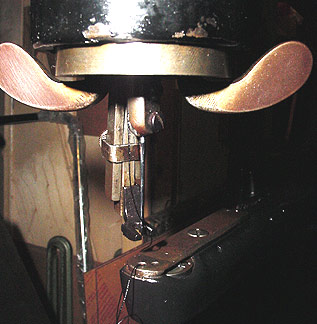

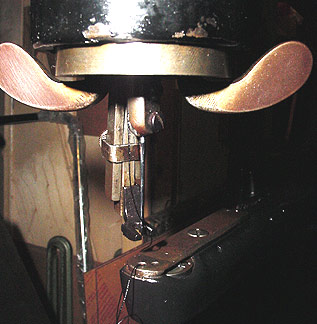

Also for leather are my two old Singer "Patchers"

- one of them is shown below:

Yes, the patchers are treadle or hand powered. These

machines will sew up to 1/4" thick leather - in any direction.

The patchers have

a long narrow bed for reaching into confined areas.

The patchers have

a long narrow bed for reaching into confined areas.

This unique construction

allows 360 degree sewing.

The direction of the feed can be changed while sewing

without turning the material.

This unique construction

allows 360 degree sewing.

The direction of the feed can be changed while sewing

without turning the material.

This old cylinder

bed machine comes in handy for some special projects.

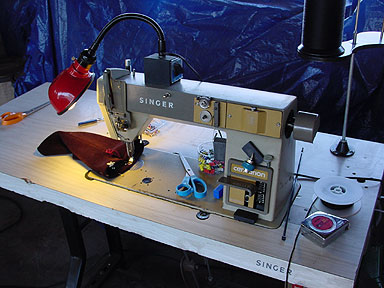

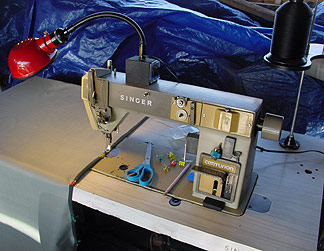

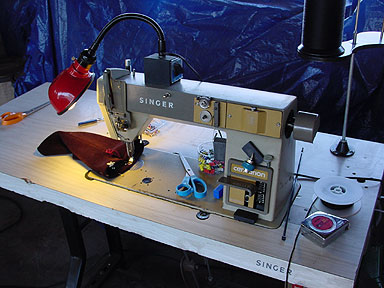

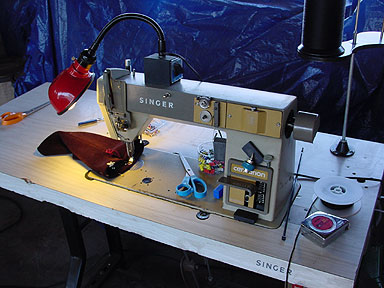

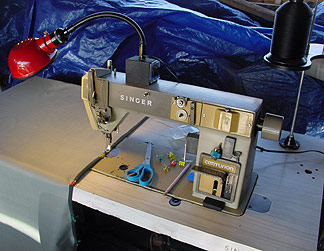

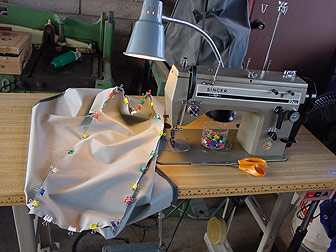

For all around straight stitch work I like to use my

Singer Centurion machine.

This old cylinder

bed machine comes in handy for some special projects.

For all around straight stitch work I like to use my

Singer Centurion machine.

If I might require a zig zag stitch, I will most often

use my Singer 20U33 machine.

This machine will sew up to a 9 mm. wide zig zag or

satin stitch.

If I might require a zig zag stitch, I will most often

use my Singer 20U33 machine.

This machine will sew up to a 9 mm. wide zig zag or

satin stitch. The controls at both ends are shown here.

The controls at both ends are shown here.

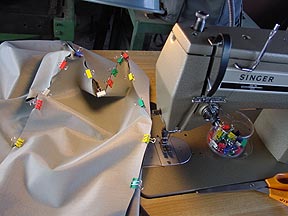

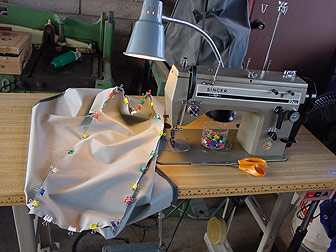

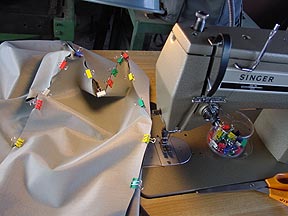

Here is the machine

sewing a waterproof cover.

Here is the machine

sewing a waterproof cover.

This is a completed

machine cover held in place by magnets.

I also have this old blind hem machine available when

needed.

This is a completed

machine cover held in place by magnets.

I also have this old blind hem machine available when

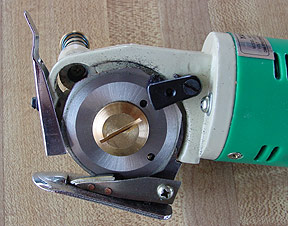

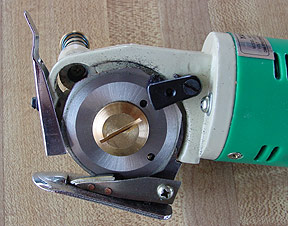

needed. I cut my fabrics with these tools.

I cut my fabrics with these tools.

For "sticky" materials, I'll often switch

to a form of roller foot to eliminate friction.

For "sticky" materials, I'll often switch

to a form of roller foot to eliminate friction.

Industrial threads are stored under the "Boss"

or in plastic storage tubs.

Industrial threads are stored under the "Boss"

or in plastic storage tubs.

In addition to the above machines, I have an old all

metal Kenmore zig-zag machine for work on certain items. It is

a very nice solid machine.

In addition to the above machines, I have an old all

metal Kenmore zig-zag machine for work on certain items. It is

a very nice solid machine.

I consider a good industrial sewing machine to be a

necessity in a well equipped shop.

I consider a good industrial sewing machine to be a

necessity in a well equipped shop.

This Tippmann "Boss"

is for leather (up to 3/4" thick) and nylon webbing. It is

hand powered.

This Tippmann "Boss"

is for leather (up to 3/4" thick) and nylon webbing. It is

hand powered.

The patchers have

a long narrow bed for reaching into confined areas.

The patchers have

a long narrow bed for reaching into confined areas. This unique construction

allows 360 degree sewing.

This unique construction

allows 360 degree sewing.

This old cylinder

bed machine comes in handy for some special projects.

This old cylinder

bed machine comes in handy for some special projects.

Here is the machine

sewing a waterproof cover.

Here is the machine

sewing a waterproof cover.

This is a completed

machine cover held in place by magnets.

This is a completed

machine cover held in place by magnets.