The Various Steps in Making

the Special Coin

For the Riser/Loomis Micro Chop

Cup

Copyright 2002 by James P. Riser

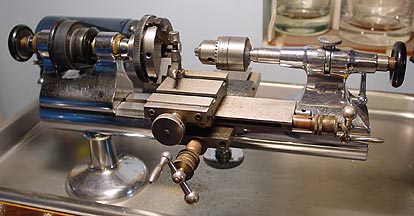

Ordinarily

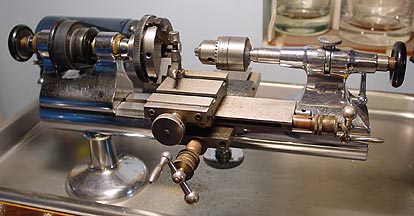

I would make these coins on my much larger Elgin industrial lathe

with much more power. The lathe to be used in making the example

gimmicked coin is a vintage watchmaker's lathe which I have converted

to two step variable speed with a much larger than normal DC motor.

I like to use this high accuracy lathe for creating prototypes.

It has a wide range of accessories

for various ultra-precision machining tasks.

It is shown here with a three

jaw scroll chuck, three way cross slide, and a drill chuck in

position.

These relatively less accurate

chucks will not be used for coin work.

Ordinarily

I would make these coins on my much larger Elgin industrial lathe

with much more power. The lathe to be used in making the example

gimmicked coin is a vintage watchmaker's lathe which I have converted

to two step variable speed with a much larger than normal DC motor.

I like to use this high accuracy lathe for creating prototypes.

It has a wide range of accessories

for various ultra-precision machining tasks.

It is shown here with a three

jaw scroll chuck, three way cross slide, and a drill chuck in

position.

These relatively less accurate

chucks will not be used for coin work.

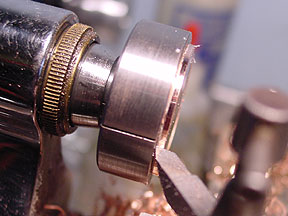

The tailstock is removed from

the lathe and the scroll chuck is removed from the headstock spindle.

Shown here is the headstock modified

for two speed steps and the completely variable speed DC motor.

A specially made collet will

be used to grip the coin for machining.

The coin to be made is a Sacagewea

dollar with a steel shim and plain copper "tails" side.

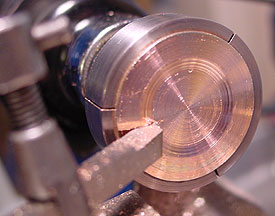

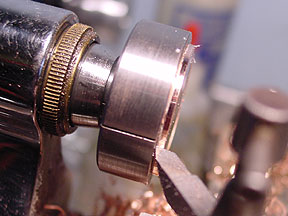

This is the special collet with

a recess machined into it for holding the coin.

The tailstock is removed from

the lathe and the scroll chuck is removed from the headstock spindle.

Shown here is the headstock modified

for two speed steps and the completely variable speed DC motor.

A specially made collet will

be used to grip the coin for machining.

The coin to be made is a Sacagewea

dollar with a steel shim and plain copper "tails" side.

This is the special collet with

a recess machined into it for holding the coin.

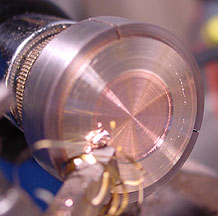

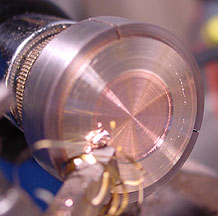

The coin is mounted in this collet with the "tails"

side out.

The coin is mounted in this collet with the "tails"

side out.  The motor is set to an appropriate

speed and the machining begins.

The motor is set to an appropriate

speed and the machining begins.

The thickness is reduced and a depression is machined to hold

the steel shim.

The thickness is reduced and a depression is machined to hold

the steel shim. Accurate measurements are taken

often as the machining is done.

Accurate measurements are taken

often as the machining is done.

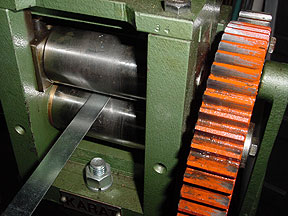

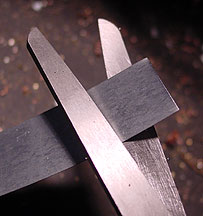

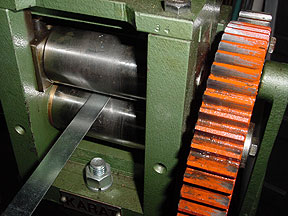

A strip of steel is sheared from a sheet of .020" thick steel.

A strip of steel is sheared from a sheet of .020" thick steel.

This steel strip is too thick

for the required shim.....

This steel strip is too thick

for the required shim.....

....so it is rolled until it is only .005" thick.

The top strip is the thicker

steel and the bottom strip is the rolled shim steel.

....so it is rolled until it is only .005" thick.

The top strip is the thicker

steel and the bottom strip is the rolled shim steel.

This shim steel is cut to size with a scissors.

Copper (and nickel silver - for

other coins) discs are punched out ready to be flattened.

This shim steel is cut to size with a scissors.

Copper (and nickel silver - for

other coins) discs are punched out ready to be flattened.

The discs are flattened with a stamping tool.

The discs are flattened with a stamping tool.  Industrial grade high-tech adhesive

is placed into the depression.

Industrial grade high-tech adhesive

is placed into the depression.

The steel shim is set in to position.

Additional adhesive is applied

for securing the flattened copper disc to the back of the coin.

The steel shim is set in to position.

Additional adhesive is applied

for securing the flattened copper disc to the back of the coin.

Things are clamped until fully set.

The copper disc is slightly oversized

and will require trimming on the lathe.

Things are clamped until fully set.

The copper disc is slightly oversized

and will require trimming on the lathe.

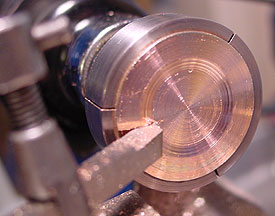

The coin is rechucked in the collet for precision edge trimming.

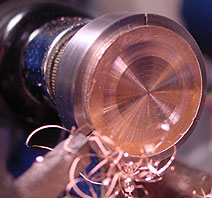

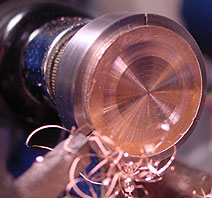

The copper is surfaced for proper

coin thickness and for flatness.

The coin is rechucked in the collet for precision edge trimming.

The copper is surfaced for proper

coin thickness and for flatness.

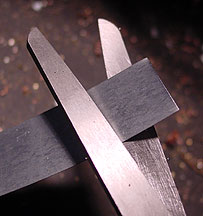

The

surface is smoothed with emery cloth and oil.

The copper will now have this

appearance.

The

surface is smoothed with emery cloth and oil.

The copper will now have this

appearance.

This

copper surface is power wire brushed to look like the inside cup

bottom.

This

copper surface is power wire brushed to look like the inside cup

bottom.

The coin edge is micro grit smoothed and buffed.

The coin edge is micro grit smoothed and buffed.

Shown

here are copper faced and nickel silver faced coins.

Shown

here are copper faced and nickel silver faced coins.  Here are a few additional views.

Here are a few additional views.

A DeLuxe Copper James Riser/Dennis

Loomis Micro Chop Cup as used for coin work.

A DeLuxe Copper James Riser/Dennis

Loomis Micro Chop Cup as used for coin work.

The special coin to be used with the Riser/Loomis Micro Chop Cup

as it is shipped.

Click

here for imformation on these cups.

The special coin to be used with the Riser/Loomis Micro Chop Cup

as it is shipped.

Click

here for imformation on these cups.

Ordinarily

I would make these coins on my much larger Elgin industrial lathe

with much more power. The lathe to be used in making the example

gimmicked coin is a vintage watchmaker's lathe which I have converted

to two step variable speed with a much larger than normal DC motor.

I like to use this high accuracy lathe for creating prototypes.

Ordinarily

I would make these coins on my much larger Elgin industrial lathe

with much more power. The lathe to be used in making the example

gimmicked coin is a vintage watchmaker's lathe which I have converted

to two step variable speed with a much larger than normal DC motor.

I like to use this high accuracy lathe for creating prototypes.

The coin is mounted in this collet with the "tails"

side out.

The coin is mounted in this collet with the "tails"

side out.

The thickness is reduced and a depression is machined to hold

the steel shim.

The thickness is reduced and a depression is machined to hold

the steel shim.

A strip of steel is sheared from a sheet of .020" thick steel.

A strip of steel is sheared from a sheet of .020" thick steel.

....so it is rolled until it is only .005" thick.

....so it is rolled until it is only .005" thick.

This shim steel is cut to size with a scissors.

This shim steel is cut to size with a scissors.

The discs are flattened with a stamping tool.

The discs are flattened with a stamping tool.

The steel shim is set in to position.

The steel shim is set in to position.

Things are clamped until fully set.

Things are clamped until fully set.

The coin is rechucked in the collet for precision edge trimming.

The coin is rechucked in the collet for precision edge trimming.

The

surface is smoothed with emery cloth and oil.

The

surface is smoothed with emery cloth and oil.

This

copper surface is power wire brushed to look like the inside cup

bottom.

This

copper surface is power wire brushed to look like the inside cup

bottom.

The coin edge is micro grit smoothed and buffed.

The coin edge is micro grit smoothed and buffed.

Shown

here are copper faced and nickel silver faced coins.

Shown

here are copper faced and nickel silver faced coins.

The special coin to be used with the Riser/Loomis Micro Chop Cup

as it is shipped.

The special coin to be used with the Riser/Loomis Micro Chop Cup

as it is shipped.