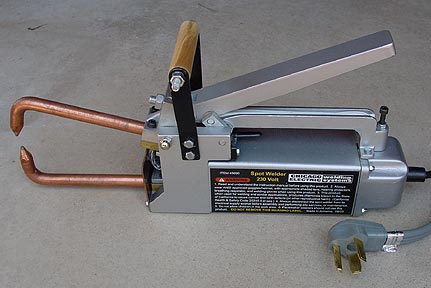

I picked up this spot welder to use with several projects that I will be working on in my shop. I wanted to be able to spot weld sheet steel, galvanized sheet, and stainless steel sheet. Shown below are the first test welds that I made with this unit. The unit comes without a plug. I added a plug to match our clothes dryer outlet and an outlet I already have in my shop.

The maximum capabilities of the unit are supposedly 3/16" thick steel. I gave it a try on a couple old pieces of 1/8" angle steel (1/4" total thickness) just to see what would happen. The areas to be welded were first ground down to clean metal to make good electrical contacts. Amazingly the little welder actually welded the pieces together rather well! I used an offset 3 tack weld to help make a stronger joint. It is shown here as it came from being welded:

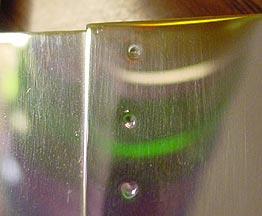

Below the welds have been lightly sanded down to clean metal to see what the finished welds would look like - not too shabby. These will be fine when painted.

My biggest planned use is to weld stainless steel then polish up the joints to make them more acceptable. Shown below ate two scraps of .030" thick stainless steel which have been spot welded together. As you can see, I was experimenting with weld times (hence slightly varying tack marks). Again, the little welder performed up to my expectations.