Restoring a Gorton 3U Pantograph - Part 2

Copyright 2006 by James P. Riser

As soon as the fonts arrive, I'll post images

of a couple sample engravings and a couple work holding devices.

In the mean time I'll clean up another style of type holder and

a few assorted extras to go with the machine.

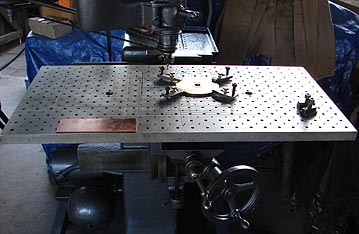

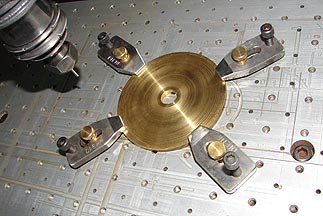

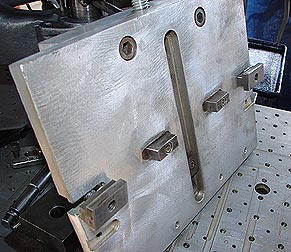

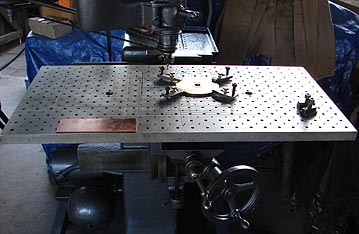

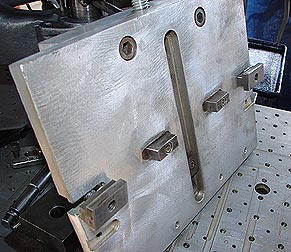

Work holding is always a problem on pantographs. Below

is one solution for holding thin items for profile cutting or

engraving...

A 1" thick

aluminum plate is drilled and tapped with a grid of holes.

Another view...

A 1" thick

aluminum plate is drilled and tapped with a grid of holes.

Another view...  This plate is attached to the pantograph work table

with T-slot standard hold down fittings...

This plate is attached to the pantograph work table

with T-slot standard hold down fittings...

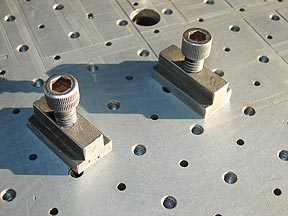

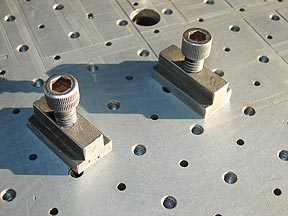

Any number of standard

clamps are used to hold the metal.

Notice the traces of previous cutouts from the previous

owner on the metal plate surface.

Any number of standard

clamps are used to hold the metal.

Notice the traces of previous cutouts from the previous

owner on the metal plate surface.  I plan on placing a thin sacrificial layer of acetate

sheet between the aluminum plate and the thin metals that I will

be profile cutting with this machine.

The use of such clamps allows clamping irregularly

shaped items and free access of the spindle cutter to the metal

surface.

I plan on placing a thin sacrificial layer of acetate

sheet between the aluminum plate and the thin metals that I will

be profile cutting with this machine.

The use of such clamps allows clamping irregularly

shaped items and free access of the spindle cutter to the metal

surface.

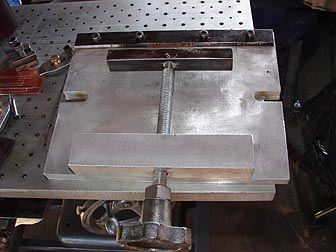

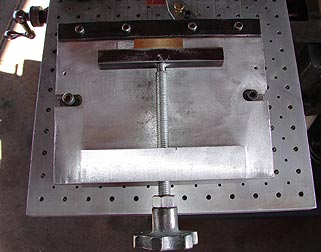

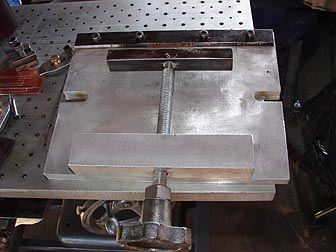

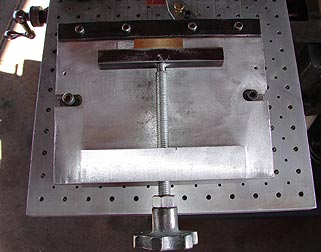

A shop made vise for the Gorton 3U...

This thin material holding vise was put together from

scrap materials sitting around the shop. It was made for another

machine; but fits the Gorton 3U perfectly. The jaws of this homemade

vise are tapered for cutter clearance.

A shop made vise for the Gorton 3U...

This thin material holding vise was put together from

scrap materials sitting around the shop. It was made for another

machine; but fits the Gorton 3U perfectly. The jaws of this homemade

vise are tapered for cutter clearance.

It attaches to

the Gorton table using the T-slots. It is not attached in these

images.

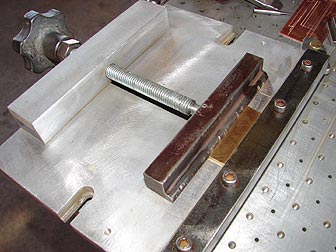

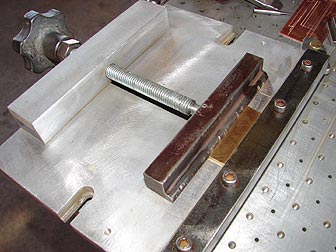

Here is an underneath view showing stationary blocks

for alignment...

It attaches to

the Gorton table using the T-slots. It is not attached in these

images.

Here is an underneath view showing stationary blocks

for alignment...

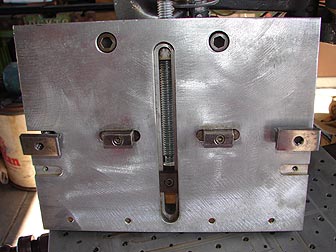

And another view

showing alignment blocks and T-slot hold downs.

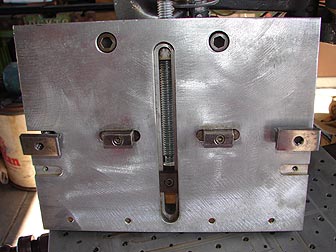

The vise holding a thin piece of brass; but vise not

clamped down to the 3U table.

And another view

showing alignment blocks and T-slot hold downs.

The vise holding a thin piece of brass; but vise not

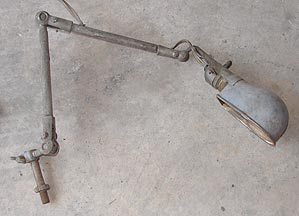

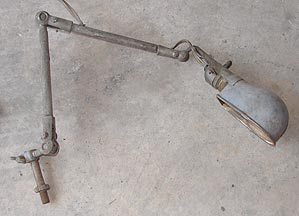

clamped down to the 3U table.  The lamp...

On the left side of the Gorton 3U is a steel "bar"

which sticks out...

The lamp...

On the left side of the Gorton 3U is a steel "bar"

which sticks out... A duplicate "bar" is seen on the lamp below.

I still need to clean and paint this lamp.

A duplicate "bar" is seen on the lamp below.

I still need to clean and paint this lamp.

This "bar"

is a mount for the official Gorton lamp...

This "bar"

is a mount for the official Gorton lamp...

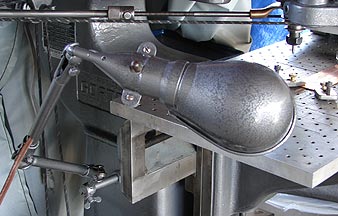

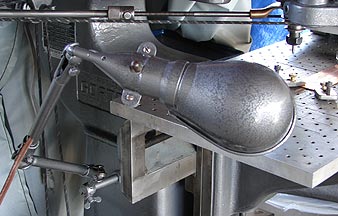

The lamp cleaned

up, painted, rewired, and in position...

A close-up of the lamp clamp...

The lamp cleaned

up, painted, rewired, and in position...

A close-up of the lamp clamp...  The fonts have arrived!

The fonts have arrived!

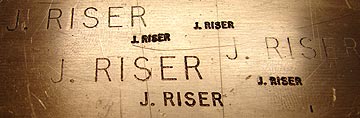

A sample set up

for trial...

A sample set up

for trial... Until I get around to machining some type stops, I

am using powerful magnets to hold things in place.

I lightly oil the template letters to prevent wear

on them...

Until I get around to machining some type stops, I

am using powerful magnets to hold things in place.

I lightly oil the template letters to prevent wear

on them...

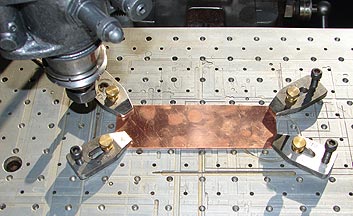

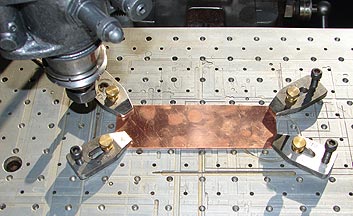

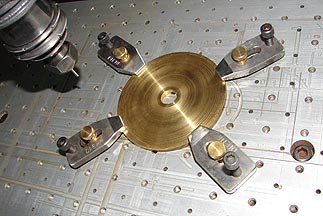

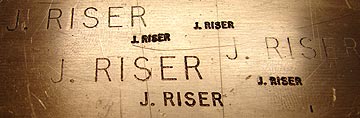

Engraving a piece

of scrap copper...

Engraving a piece

of scrap copper...

And some easier

to engrave brass...

And some easier

to engrave brass... And a sample engraved on a better piece of brass...

And a sample engraved on a better piece of brass...

Another brass sample engraving with penny to show scale...

Another brass sample engraving with penny to show scale...

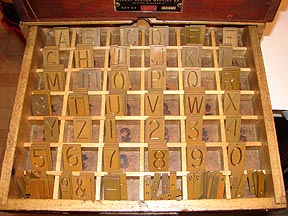

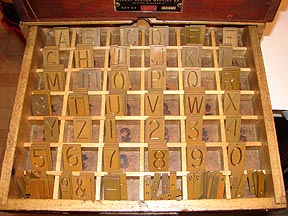

With the assorted

Gorton fonts I also received a 2 1/4" high letter set.

These are too large for the standard holder and too

small for the larger 3 1/2" Gorton type holder.

I'll machine a tapered top guide strip to secure the

letters.

This guide strip will be screwed to the type holder

shown so that these large letters may be utilized.

With the assorted

Gorton fonts I also received a 2 1/4" high letter set.

These are too large for the standard holder and too

small for the larger 3 1/2" Gorton type holder.

I'll machine a tapered top guide strip to secure the

letters.

This guide strip will be screwed to the type holder

shown so that these large letters may be utilized.

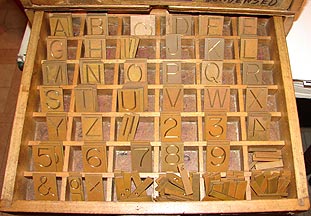

Done. The camera

makes the holder appear to be bowed on top. It is straight.

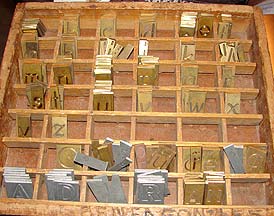

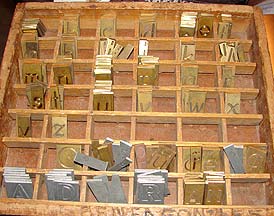

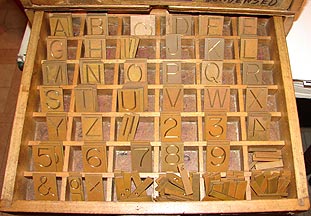

Here are a few fonts that I have found for this machine

(block, condensed, reverse, raised, monogram, etc.):

Done. The camera

makes the holder appear to be bowed on top. It is straight.

Here are a few fonts that I have found for this machine

(block, condensed, reverse, raised, monogram, etc.):

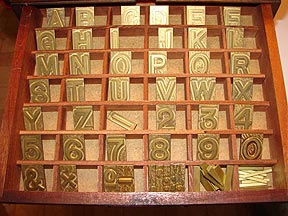

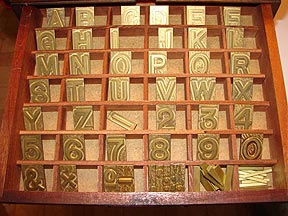

Cursive Caps and

lower case

Cursive Caps and

lower case  A raised reverse font for making steel stamps.

A raised reverse font for making steel stamps.  Click here to see a quick

overview of all of the fonts that I have acquired in my travels.

Click here to go to part 3

of the restoration.

Click here to see a quick

overview of all of the fonts that I have acquired in my travels.

Click here to go to part 3

of the restoration.

A 1" thick

aluminum plate is drilled and tapped with a grid of holes.

A 1" thick

aluminum plate is drilled and tapped with a grid of holes. A 1" thick

aluminum plate is drilled and tapped with a grid of holes.

A 1" thick

aluminum plate is drilled and tapped with a grid of holes.

Any number of standard

clamps are used to hold the metal.

Any number of standard

clamps are used to hold the metal.

It attaches to

the Gorton table using the T-slots. It is not attached in these

images.

It attaches to

the Gorton table using the T-slots. It is not attached in these

images.

And another view

showing alignment blocks and T-slot hold downs.

And another view

showing alignment blocks and T-slot hold downs.

This "bar"

is a mount for the official Gorton lamp...

This "bar"

is a mount for the official Gorton lamp...

The lamp cleaned

up, painted, rewired, and in position...

The lamp cleaned

up, painted, rewired, and in position...

A sample set up

for trial...

A sample set up

for trial...

Engraving a piece

of scrap copper...

Engraving a piece

of scrap copper...

And some easier

to engrave brass...

And some easier

to engrave brass...

With the assorted

Gorton fonts I also received a 2 1/4" high letter set.

With the assorted

Gorton fonts I also received a 2 1/4" high letter set. Done. The camera

makes the holder appear to be bowed on top. It is straight.

Done. The camera

makes the holder appear to be bowed on top. It is straight.

Cursive Caps and

lower case

Cursive Caps and

lower case