Restoring a Gorton 3U Pantograph - Part 3

Copyright 2006 by James P. Riser

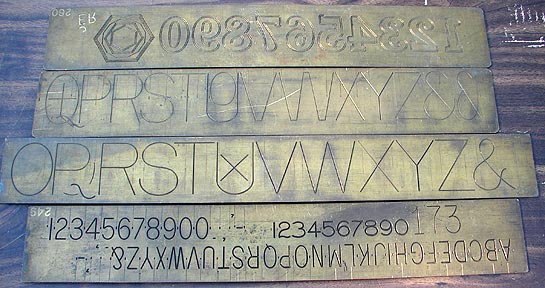

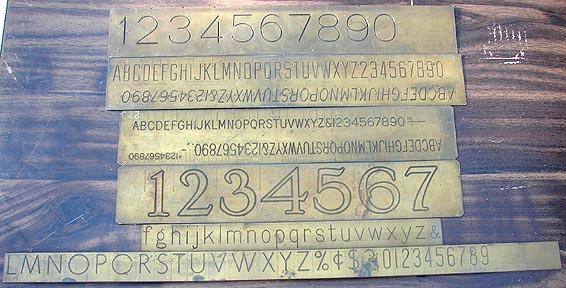

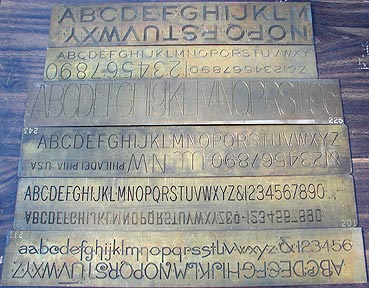

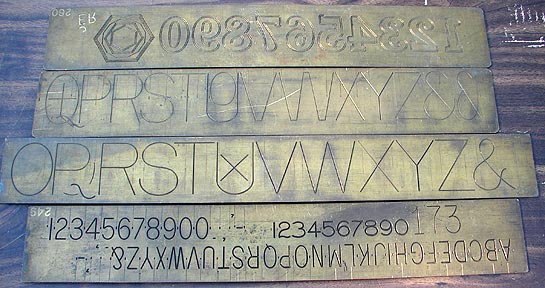

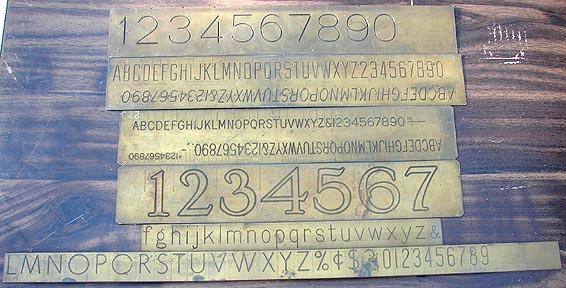

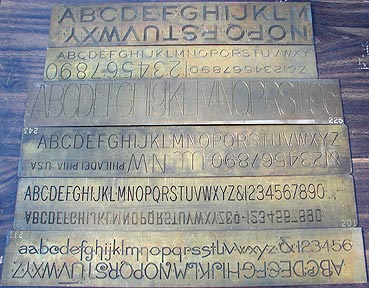

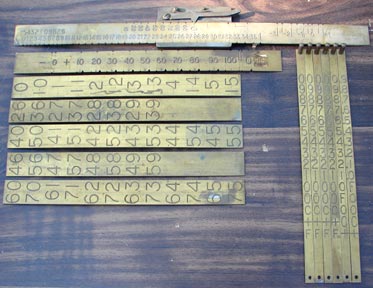

Fonts for the 3U continued...

I hit the font treasure trove! Below are master font

strips. Since my 3U can do 1:1 ratios, I can make additional font

sets from these master strips.

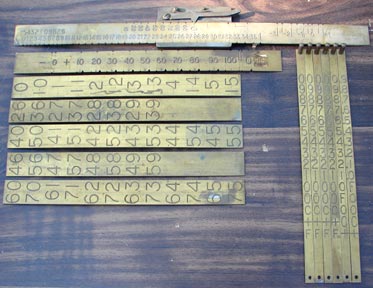

I also picked up a number of profile guides for engraving

on other than flat surfaces. The spindle can be set to follow

custom curved surfaces using such guides.

I also picked up a number of profile guides for engraving

on other than flat surfaces. The spindle can be set to follow

custom curved surfaces using such guides.

I received them

in this type of condition.

I received them

in this type of condition.  Cleaned up, they look just fine.

Cleaned up, they look just fine.

There is no use having a pantograph without being able

to grind the single lip cutters. I bought a Gorton single lip

grinder for a song on ebay. It was a pick it up special and was

near my younger son's place. I'll get it from him next month.

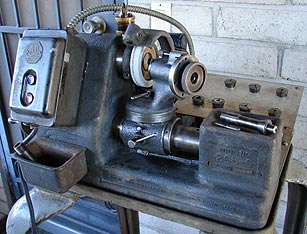

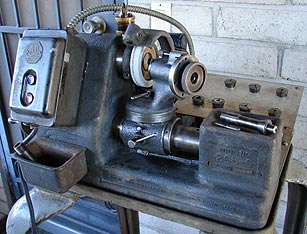

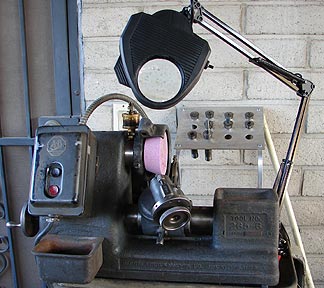

I finally picked up and cleaned the Gorton 265-6 tool

and cutter grinder. The Gorton is extremely heavy duty!

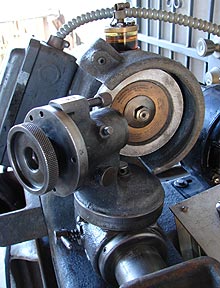

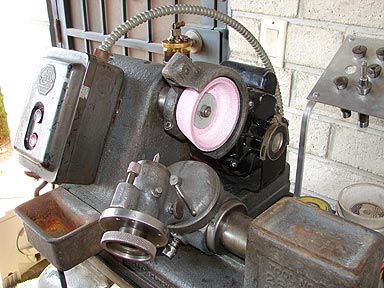

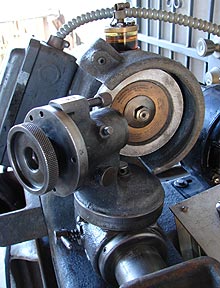

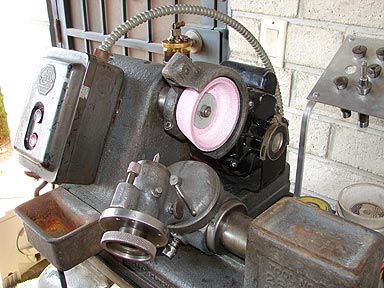

Here are a few images of the Gorton grinder.

Now all I need is a diamond wheel for the Gorton for

grinding carbide.

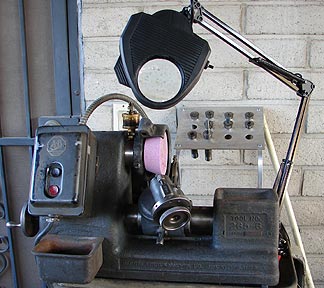

Things are now finished with the Gorton Grinder.

Here is the final setup...

Now all I need is a diamond wheel for the Gorton for

grinding carbide.

Things are now finished with the Gorton Grinder.

Here is the final setup...

I have decided

not to repaint this grinder since grinding messes everything up

any way.

I have decided

not to repaint this grinder since grinding messes everything up

any way.

Note the magnifying

lamp and collet rack.

Note the magnifying

lamp and collet rack. I have located an assortment of grinding wheels besides

the worn white wheel that came with the old Gorton grinder.

I have located an assortment of grinding wheels besides

the worn white wheel that came with the old Gorton grinder.

Two types of pink

wheels for HSS grinding

Two types of pink

wheels for HSS grinding

Green and diamond

wheels for grinding carbide

Green and diamond

wheels for grinding carbide  I just waltzed into a few more wheels for the grinder

at a used equipment dealer's.

I just waltzed into a few more wheels for the grinder

at a used equipment dealer's.

Norton and ATVB

wheels

Norton and ATVB

wheels  I am now ready to engrave!

Here is a sample of a cone shaped single lip cutter.

I am now ready to engrave!

Here is a sample of a cone shaped single lip cutter.

And this is a sample engraving on nickel silver done

with the above cutter.

And this is a sample engraving on nickel silver done

with the above cutter.

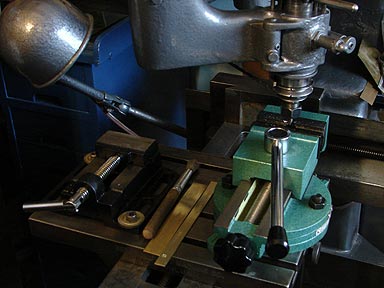

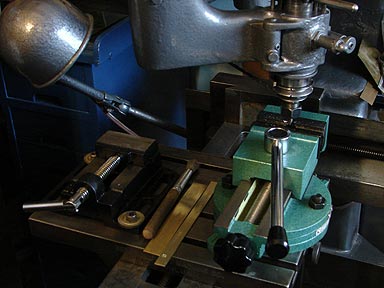

Here is the final quick-to-use work holding set up

for most small items that I will be engraving...

Here is the final quick-to-use work holding set up

for most small items that I will be engraving...

I picked up the small vise on the left in Pigeon Forge

at a tool place and the vise on the right I picked up at Grizzly

in Springfield.

The Grizzly vise has a small lip just inside of the

jaws making it perfect for shallow holding of items to be engraved.

This eliminates needing to use parallels for work holding.

In addition, I use this Hardinge indexing fixture for

a number of items that I manufacture requiring engravings to be

accurately spaced around the items. This allows for placing engravings

in 2, 3, 4, 6, 8 ,12, or 24 equally spaced positions. It is used

with 5C pot or step collets; but can handle a faceplate or chuck,

if the job needs this feature.

I picked up the small vise on the left in Pigeon Forge

at a tool place and the vise on the right I picked up at Grizzly

in Springfield.

The Grizzly vise has a small lip just inside of the

jaws making it perfect for shallow holding of items to be engraved.

This eliminates needing to use parallels for work holding.

In addition, I use this Hardinge indexing fixture for

a number of items that I manufacture requiring engravings to be

accurately spaced around the items. This allows for placing engravings

in 2, 3, 4, 6, 8 ,12, or 24 equally spaced positions. It is used

with 5C pot or step collets; but can handle a faceplate or chuck,

if the job needs this feature.

Here it is with

a small 5C collet for engraving things like letter stamps...

Here it is with

a small 5C collet for engraving things like letter stamps...

and with a pot

chuck empty and with metal to be engraved...

and with a pot

chuck empty and with metal to be engraved... A close up of the vise in action...

A close up of the vise in action...

I was able to locate a few end stops so I did not need

to make my own. Here are a couple end stops in action when engraving

the above sample plate...

I was able to locate a few end stops so I did not need

to make my own. Here are a couple end stops in action when engraving

the above sample plate...

Conclusions:

Conclusions:

This old Gorton 3U pantograph machine willl definitely meet

my engraving needs. I am pleased with the looks of the machine

and the fact that it still works quite well. Big job...whew!

Click here to see the dial

engraving accessory.

Click here to go to my Gorton

265 grinder page.

I received them

in this type of condition.

I received them

in this type of condition.

I have decided

not to repaint this grinder since grinding messes everything up

any way.

I have decided

not to repaint this grinder since grinding messes everything up

any way. Note the magnifying

lamp and collet rack.

Note the magnifying

lamp and collet rack.

Two types of pink

wheels for HSS grinding

Two types of pink

wheels for HSS grinding

Green and diamond

wheels for grinding carbide

Green and diamond

wheels for grinding carbide

Norton and ATVB

wheels

Norton and ATVB

wheels

Here it is with

a small 5C collet for engraving things like letter stamps...

Here it is with

a small 5C collet for engraving things like letter stamps... and with a pot

chuck empty and with metal to be engraved...

and with a pot

chuck empty and with metal to be engraved...