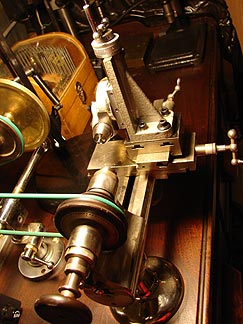

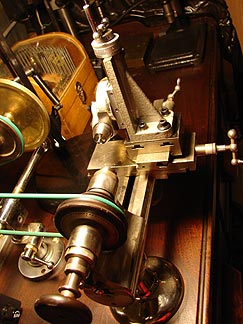

Making the index plates for drilling out lantern pinions

on the milling head.

The first step was

to cut brass discs from 2" bar.

The first step was

to cut brass discs from 2" bar.  These cut discs would be mounted in a pot chuck or

stepped collet on my Sheldon lathe.

These cut discs would be mounted in a pot chuck or

stepped collet on my Sheldon lathe.

This is the collet

to be used.

This is the collet

to be used.

Here is one of

the discs mounted in the collet - note the disc stands proud of

the collet.

Here is one of

the discs mounted in the collet - note the disc stands proud of

the collet.  Using a large center drill to eliminate deflection,

the center hole is started.

Using a large center drill to eliminate deflection,

the center hole is started.

The hole is then

drilled to 1/4" diameter.

The hole is then

drilled to 1/4" diameter.

The drilled disc

is then faced off on both sides.

The drilled disc

is then faced off on both sides.

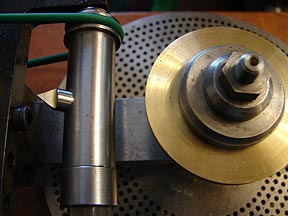

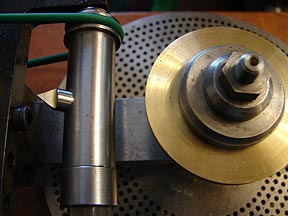

A cutter is next

carefully ground on my Gorton single lip tool grinder...

A cutter is next

carefully ground on my Gorton single lip tool grinder...

... and mounted

in the spindle of my Chronos wheel engine.

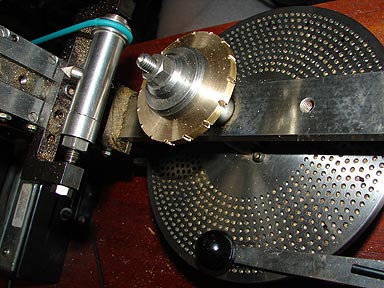

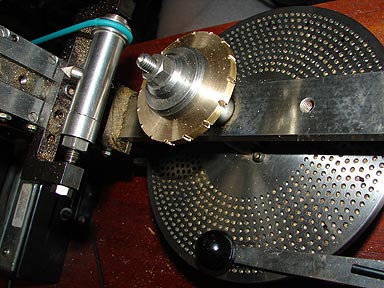

The discs are all notched with a 60 degree notch to

convert them into index plates.

... and mounted

in the spindle of my Chronos wheel engine.

The discs are all notched with a 60 degree notch to

convert them into index plates.

Another view of

the process.

Another view of

the process.

The notched discs are again faced off on the lathe

and drilled to fit the milling head draw tube.

The notched discs are again faced off on the lathe

and drilled to fit the milling head draw tube.

These 7 indexing plates will allow drilling lantern

pinions having 3, 4, 5, 6, 7, 8, 9, 10, 12, 13, 14, 15, 16, 18,

and 20 pins.

I'll use the remaining three discs to make the missing

11, 17, and 19 index plates. But I need to switch the master plate

on the Chronos wheel engine before making them.

I'll use the remaining three discs to make the missing

11, 17, and 19 index plates. But I need to switch the master plate

on the Chronos wheel engine before making them.

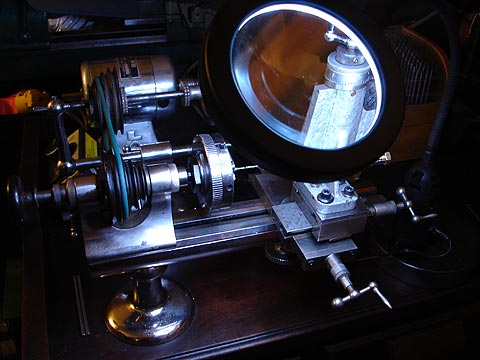

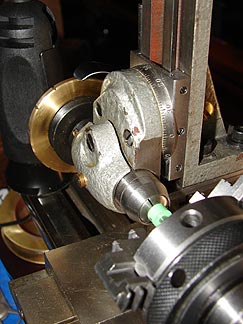

Here is the milling

head with an index plate mounted on a WW lathe.

Here is the milling

head with an index plate mounted on a WW lathe. And here it is mounted on the WW lathe set up for Pinion

drilling and milling.

And here it is mounted on the WW lathe set up for Pinion

drilling and milling.

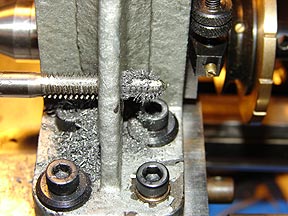

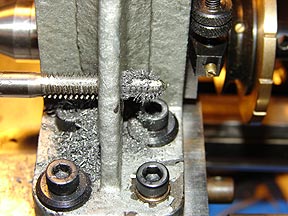

After

drilling, the milling head casting was tapped.

This is the mounting for the indexing spring.

After

drilling, the milling head casting was tapped.

This is the mounting for the indexing spring.

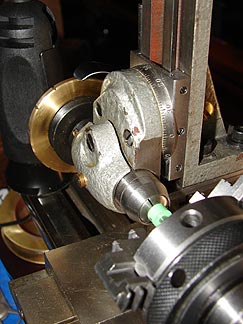

Here is the completed

indexing spring.

Here is the completed

indexing spring.

This spring just clicks into "lock" position

as the brass index wheel is rotated. It all works perfectly!

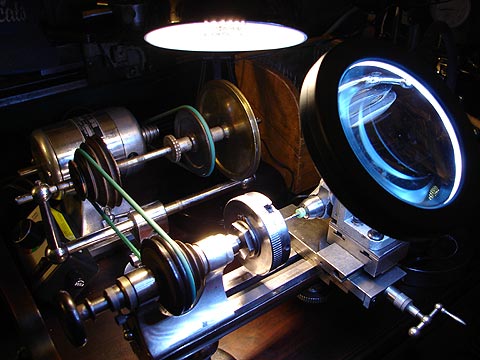

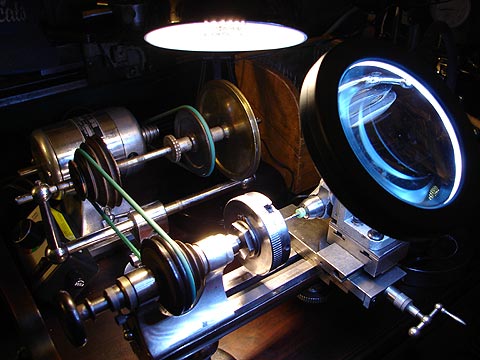

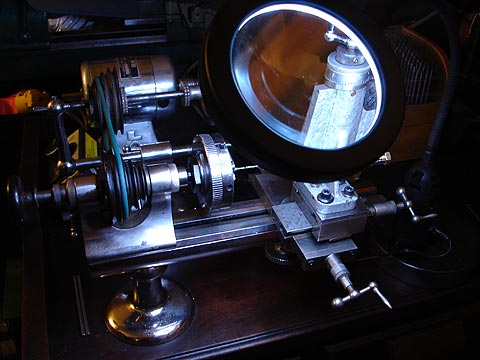

My next concern was for lighting. I located an LCD

ring magnifying lamp with magnetic base and a very intense LCD

bulb to use with a small desk lamp. These are shown below.

This spring just clicks into "lock" position

as the brass index wheel is rotated. It all works perfectly!

My next concern was for lighting. I located an LCD

ring magnifying lamp with magnetic base and a very intense LCD

bulb to use with a small desk lamp. These are shown below.

The results ...

The results ...

Ring lamp only.

Both LCD lamps on the lathe ...

Ring lamp only.

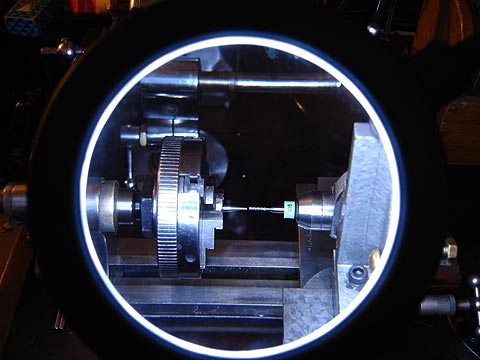

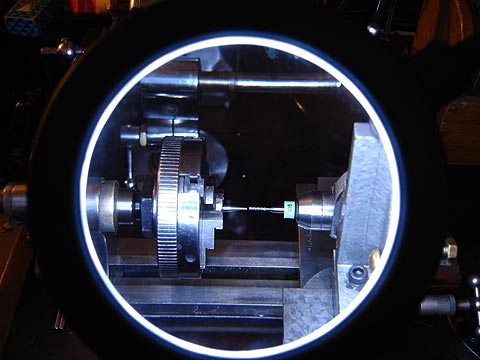

Both LCD lamps on the lathe ...  A view through the magnifying lens ...

A view through the magnifying lens ...

In conclusion, I am pleased with the final result of

this little project to make a lantern pinion drilling accessory.

Based upon what I have seen with the Chinese milling attachment,

the lathe would probably be an acceptable machine. I am so pleased

with the outcome of this project that I have also ordered the

pulley arm for supplying power to the milling head so that I can

also use it under power and not merely as an index head for drilling/milling.

Click here to go to part one.

In conclusion, I am pleased with the final result of

this little project to make a lantern pinion drilling accessory.

Based upon what I have seen with the Chinese milling attachment,

the lathe would probably be an acceptable machine. I am so pleased

with the outcome of this project that I have also ordered the

pulley arm for supplying power to the milling head so that I can

also use it under power and not merely as an index head for drilling/milling.

Click here to go to part one.

The first step was

to cut brass discs from 2" bar.

The first step was

to cut brass discs from 2" bar.

The first step was

to cut brass discs from 2" bar.

The first step was

to cut brass discs from 2" bar.

This is the collet

to be used.

This is the collet

to be used. Here is one of

the discs mounted in the collet - note the disc stands proud of

the collet.

Here is one of

the discs mounted in the collet - note the disc stands proud of

the collet.

The hole is then

drilled to 1/4" diameter.

The hole is then

drilled to 1/4" diameter. The drilled disc

is then faced off on both sides.

The drilled disc

is then faced off on both sides.

A cutter is next

carefully ground on my Gorton single lip tool grinder...

A cutter is next

carefully ground on my Gorton single lip tool grinder...

... and mounted

in the spindle of my Chronos wheel engine.

... and mounted

in the spindle of my Chronos wheel engine.

Another view of

the process.

Another view of

the process.

Here is the milling

head with an index plate mounted on a WW lathe.

Here is the milling

head with an index plate mounted on a WW lathe.

After

drilling, the milling head casting was tapped.

After

drilling, the milling head casting was tapped.

Here is the completed

indexing spring.

Here is the completed

indexing spring.

Ring lamp only.

Ring lamp only.