The Making of the Riser Ultimate Chop Cups

The "Riser Shorty" and the "Riser Tall"

Copyright 2004 by James

P. Riser

Shown here is the method that I use to make a basic

steel chuck for spinning a metal goblet shape. I prefer to utilize

steel chucks so that I might hold close tolerances on my metal

spinnings and so that the chuck will last a lifetime.

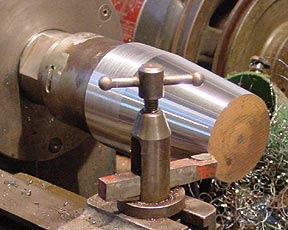

The piece of steel to be turned into the chuck is mounted

on my Sheldon metal lathe for the preliminary steps in the process.

After squaring off the end, a hole is drilled into this end. A

series of drills are used to slowly enlarge the hole up to the

size to be threaded 1" - 8 threads per inch.

This size is desired in order to mount the eventual

chuck on to an existing adapter.

The piece of steel to be turned into the chuck is mounted

on my Sheldon metal lathe for the preliminary steps in the process.

After squaring off the end, a hole is drilled into this end. A

series of drills are used to slowly enlarge the hole up to the

size to be threaded 1" - 8 threads per inch.

This size is desired in order to mount the eventual

chuck on to an existing adapter.

After drilling to the proper diameter and depth, the

hole is thread on the lathe using a large tap.

This assures a good straight thread in the chuck.

This is critical as the chuck must run true for successful

metal spinning.

Cutting oil is used during this process.

After drilling to the proper diameter and depth, the

hole is thread on the lathe using a large tap.

This assures a good straight thread in the chuck.

This is critical as the chuck must run true for successful

metal spinning.

Cutting oil is used during this process.

Shown here is the old adapter being test threaded into

the future spinning chuck

to test the size and depth of the threads.

Shown here is the old adapter being test threaded into

the future spinning chuck

to test the size and depth of the threads.

Here the adapter is shown completely threaded into

the chuck blank.

The chuck is now transferred to my Haag spinning lathe

for final shaping and truing.

Here the adapter is shown completely threaded into

the chuck blank.

The chuck is now transferred to my Haag spinning lathe

for final shaping and truing.

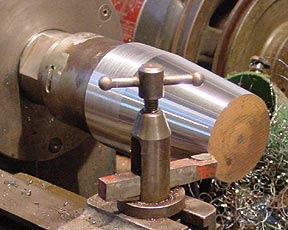

My spinning lathe

came equipped with a crossslide for making steel chucks.

A rather large pile of steel shavings is produced during

this process.

My spinning lathe

came equipped with a crossslide for making steel chucks.

A rather large pile of steel shavings is produced during

this process.

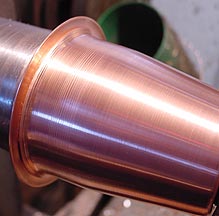

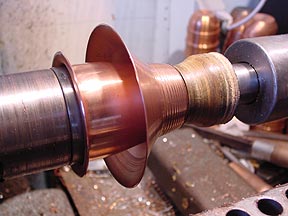

Finishing cuts

to the large taper are being cut.

Finishing cuts

to the large taper are being cut.

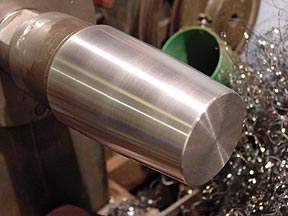

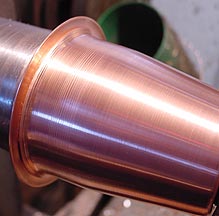

The whole chuck

is smoothed with oil and sanding cloth.

The whole chuck

is smoothed with oil and sanding cloth.  It looks like this prior to the final buffing.

It looks like this prior to the final buffing.

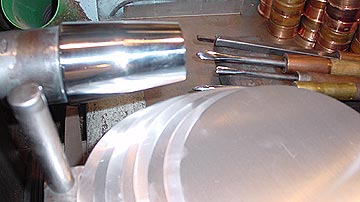

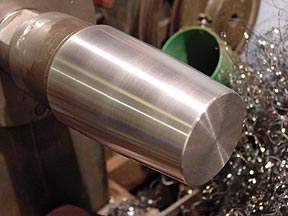

After buffing, the

completed chuck looks like this.

After buffing, the

completed chuck looks like this.

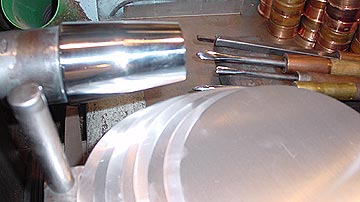

The next step is

to cut the circles for spinning.

Now everything is ready to spin!

The next step is

to cut the circles for spinning.

Now everything is ready to spin!

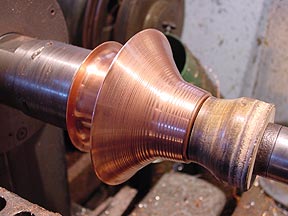

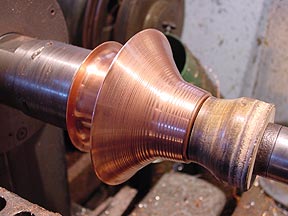

Shown here on the "Riser Tall" is

the spinning of the second layer of metal over the first.

Shown here on the "Riser Tall" is

the spinning of the second layer of metal over the first.  This casing of the base cup is shown here on the "Riser

Shorty".

This process makes the magnet assembly totally invisible

upon examination of either cup.

This casing of the base cup is shown here on the "Riser

Shorty".

This process makes the magnet assembly totally invisible

upon examination of either cup.

This outer layer of metal is carefully spun down to

the base layer. The "stuff" on the cups is spinning

lubricant.

This outer layer of metal is carefully spun down to

the base layer. The "stuff" on the cups is spinning

lubricant.

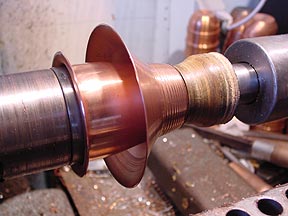

A small "flange" is formed at the rim of

this second layer of metal. This flange will be gripped by the

bead to hold everything together securely.

A small "flange" is formed at the rim of

this second layer of metal. This flange will be gripped by the

bead to hold everything together securely.

Here is shown the bead being formed over this flange.

Here is shown the bead being formed over this flange.

And the bead is completed to seal everything tightly.

And the bead is completed to seal everything tightly.

The finished cups. The Riser Shorty is designed

to deliver a tennis ball as a final load. The Riser Tall

delivers a full sized baseball.

The finished cups. The Riser Shorty is designed

to deliver a tennis ball as a final load. The Riser Tall

delivers a full sized baseball.

Click here to

return to my main magic web page.

Click here to

return to my main magic web page.

My spinning lathe

came equipped with a crossslide for making steel chucks.

My spinning lathe

came equipped with a crossslide for making steel chucks. Finishing cuts

to the large taper are being cut.

Finishing cuts

to the large taper are being cut.

The whole chuck

is smoothed with oil and sanding cloth.

The whole chuck

is smoothed with oil and sanding cloth.

After buffing, the

completed chuck looks like this.

After buffing, the

completed chuck looks like this.

The next step is

to cut the circles for spinning.

The next step is

to cut the circles for spinning.