Dial Engraving Accessory ...

Copyright 2015 by James P. Riser

This unusual Dial Engraving Accessory is the latest

addition to my Gorton 3U pantograph restoration. This accessory

allows precise engraving of flat dials or partial dials. As I

am gearing up to make a small tower clock, I can utilize this

to create the clock dials. The pictures below illustrate the accessory.

Since it fits right onto my Gorton 3U, I am assuming that it was

made by Gorton.

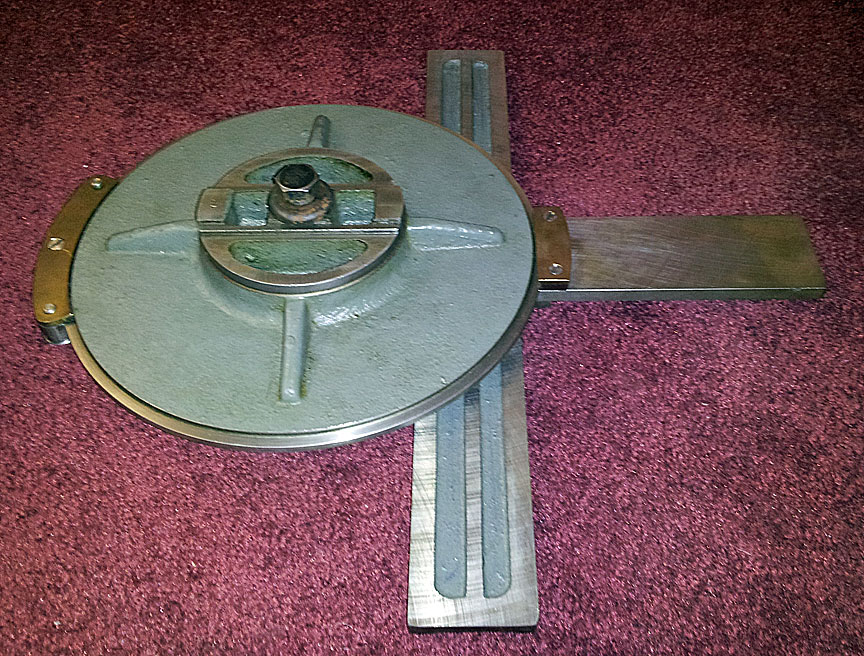

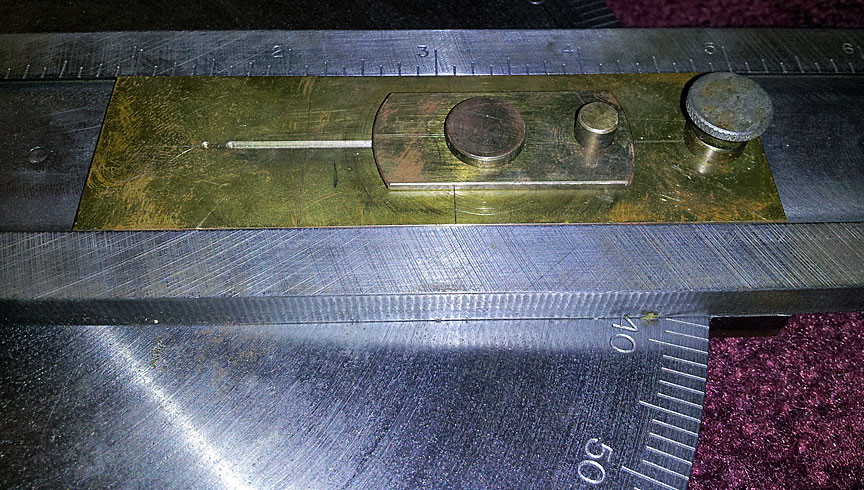

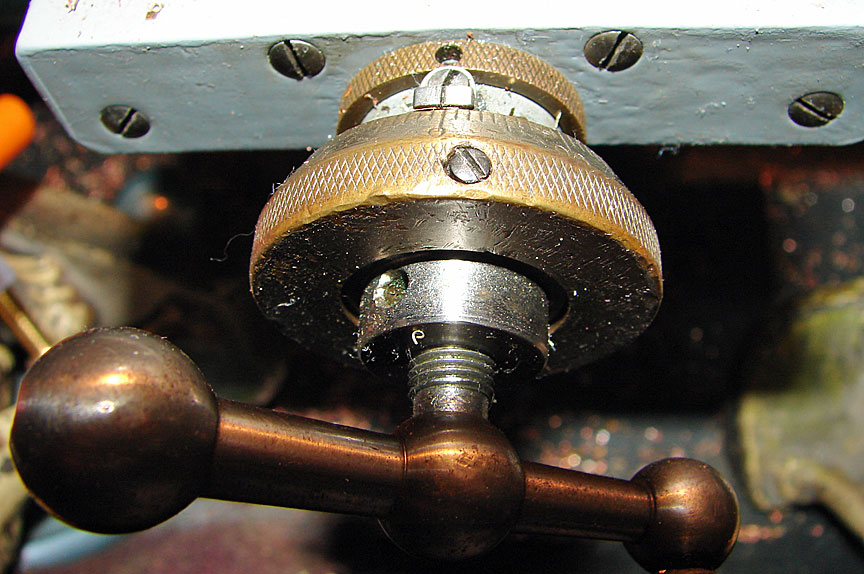

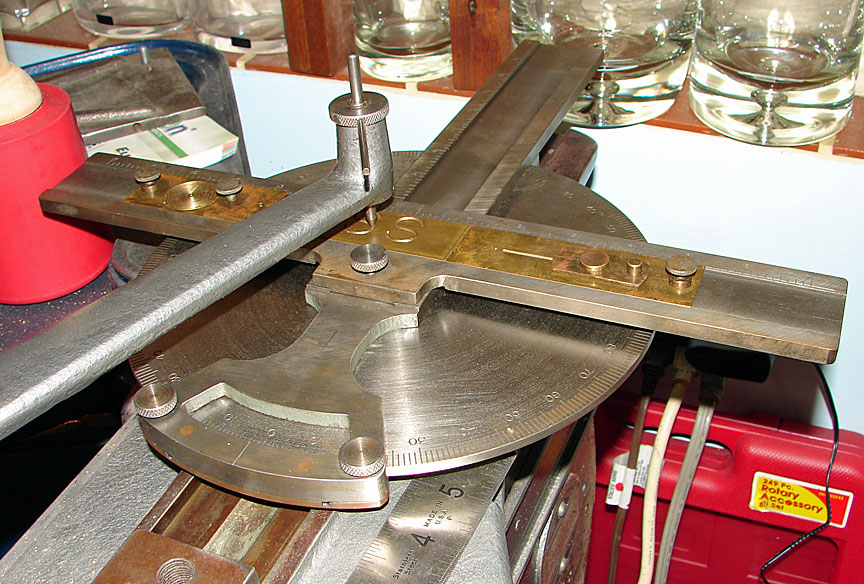

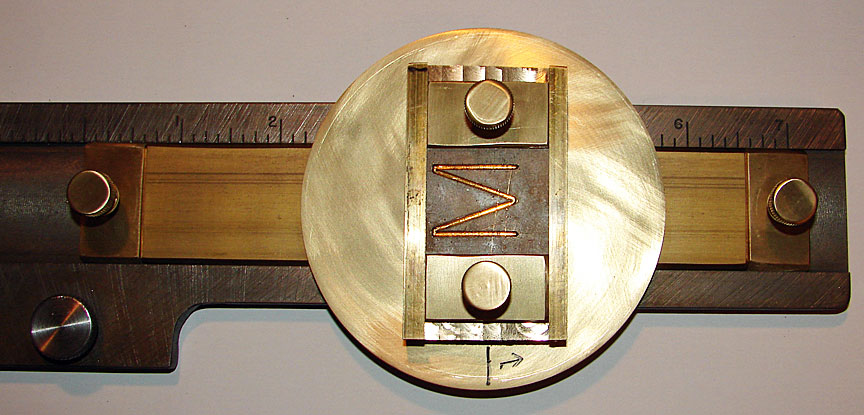

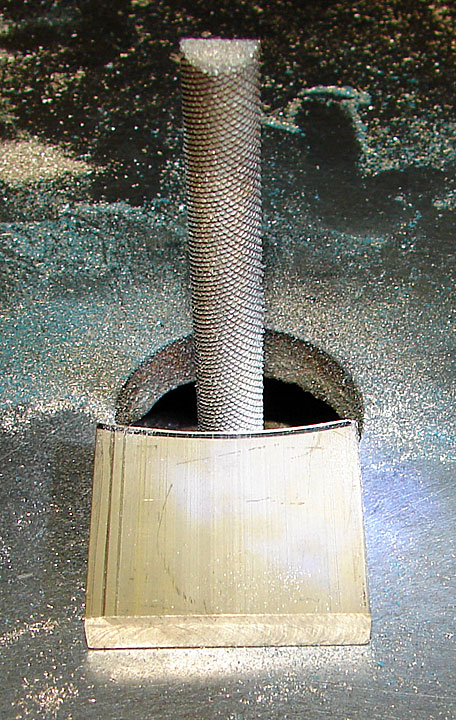

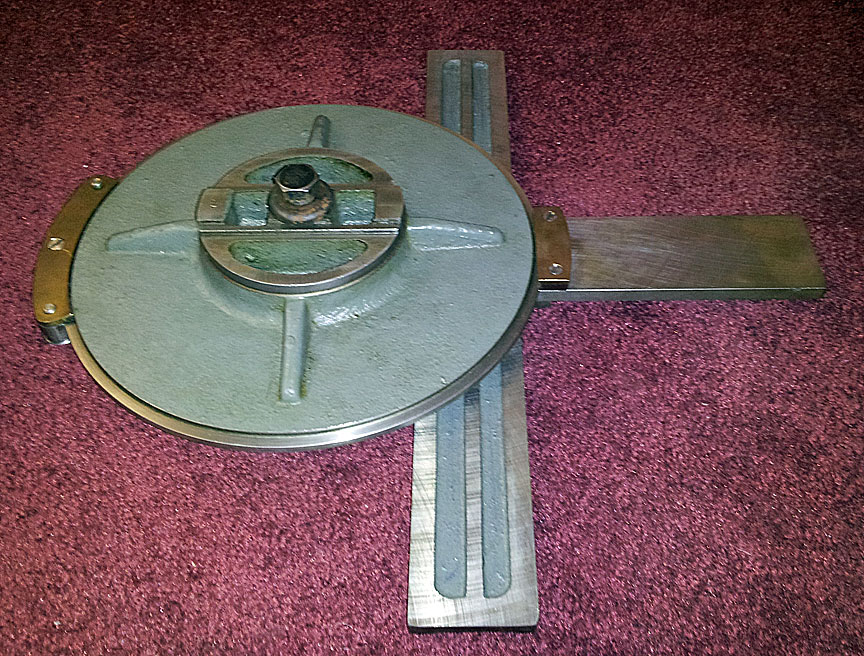

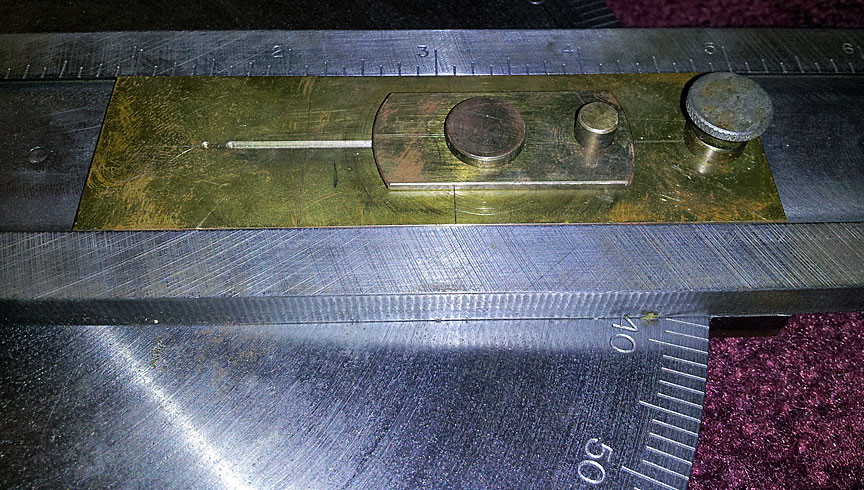

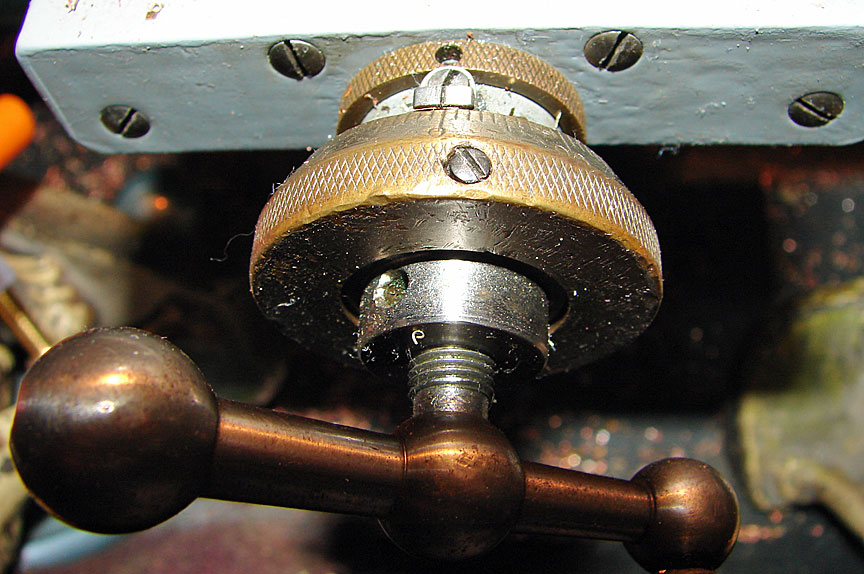

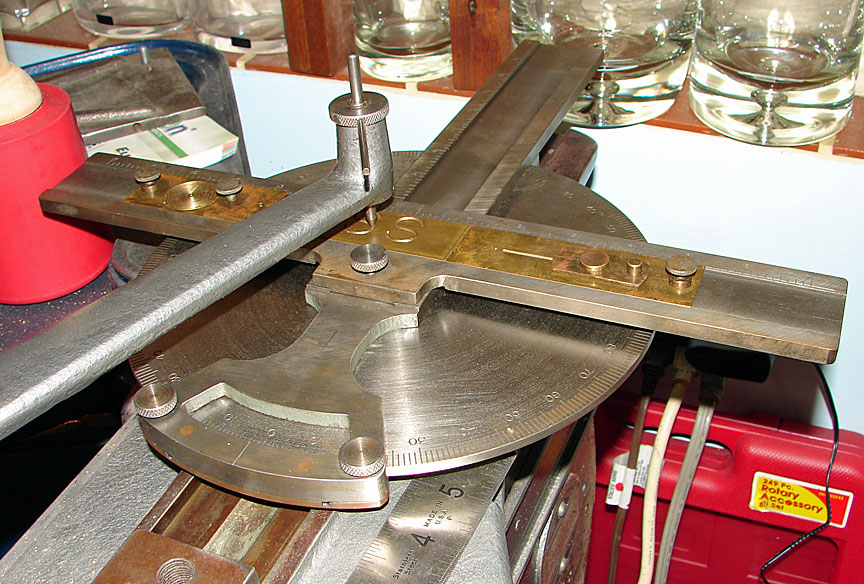

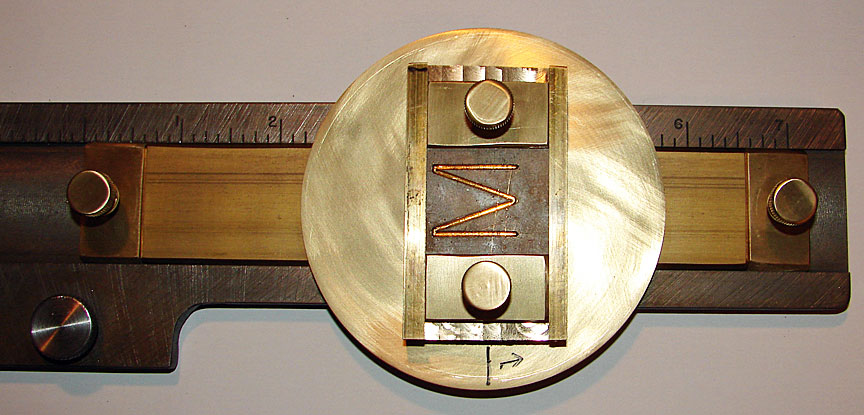

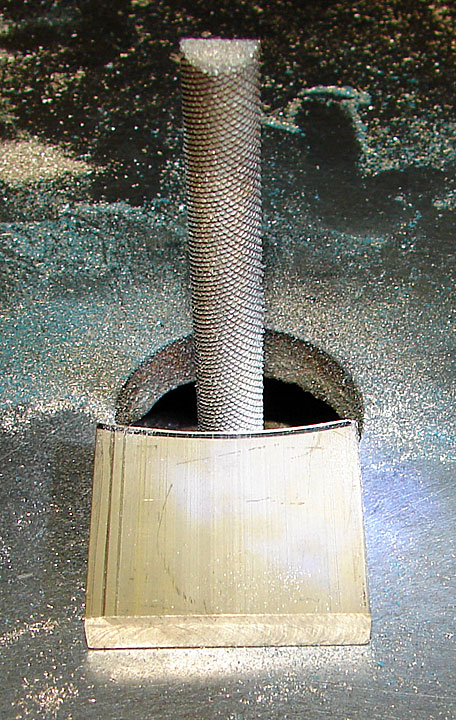

This is a view of the underside of the accessory showing

the standard mounting as seen on Gorton pantographs.

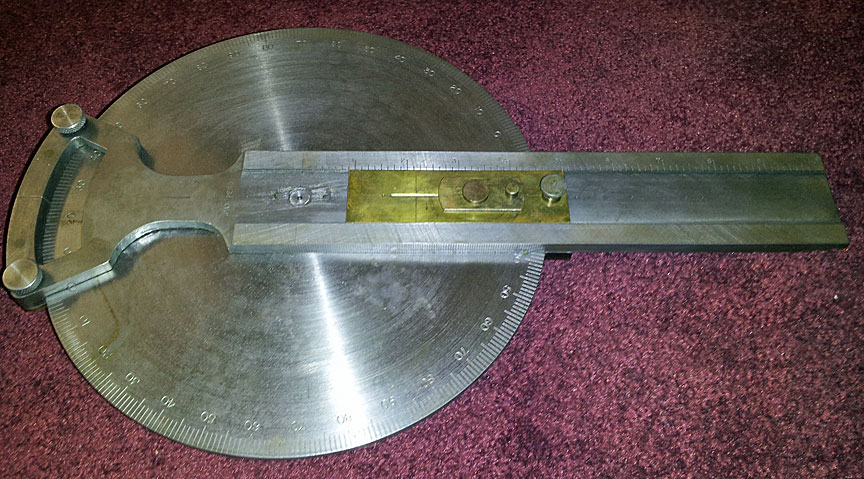

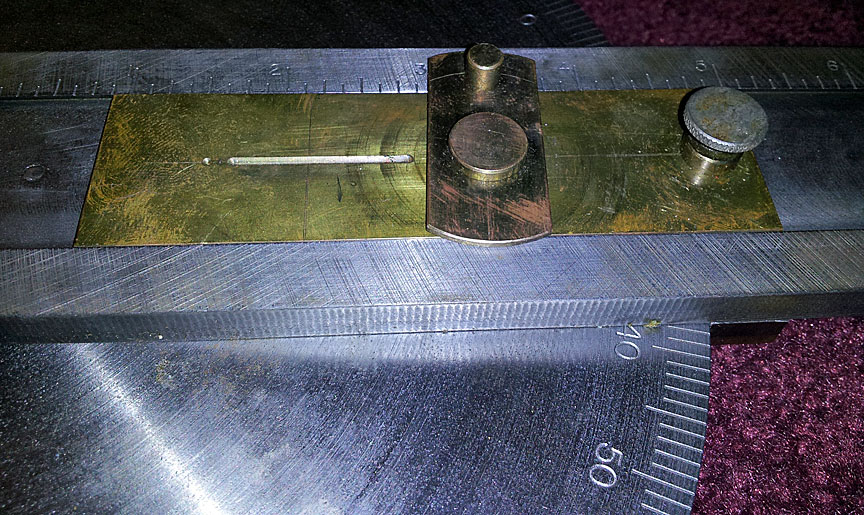

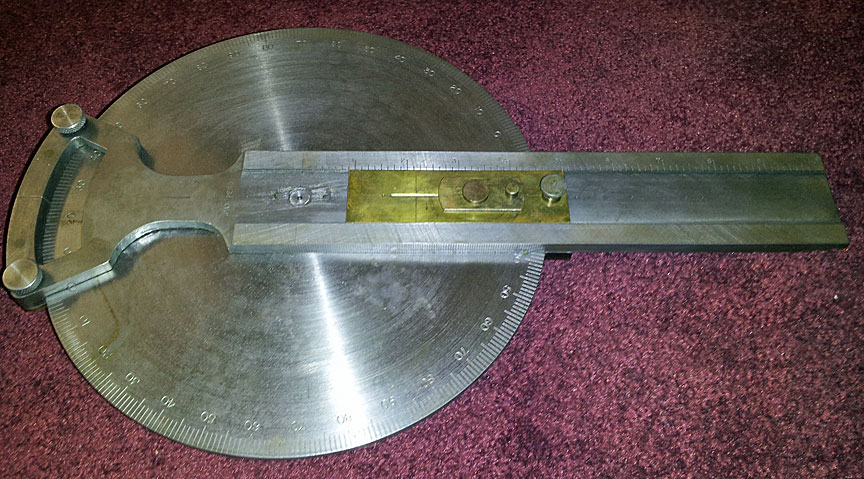

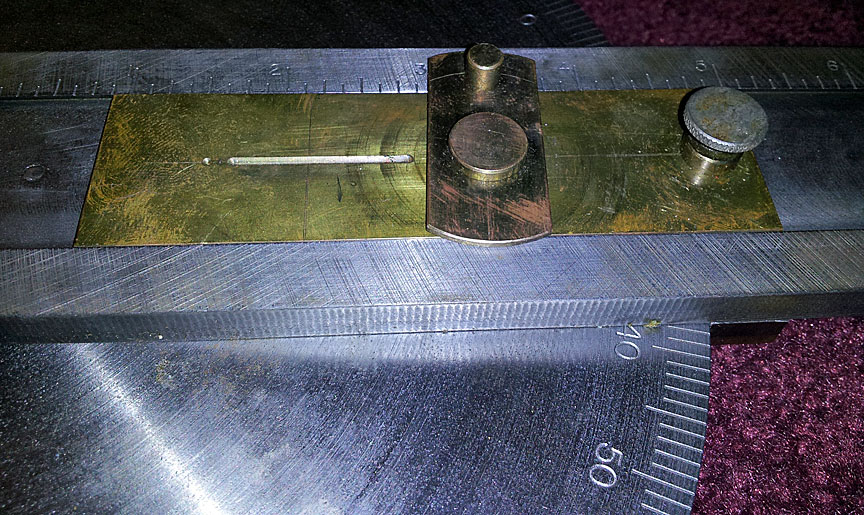

The top side looks like this.

The top side looks like this.

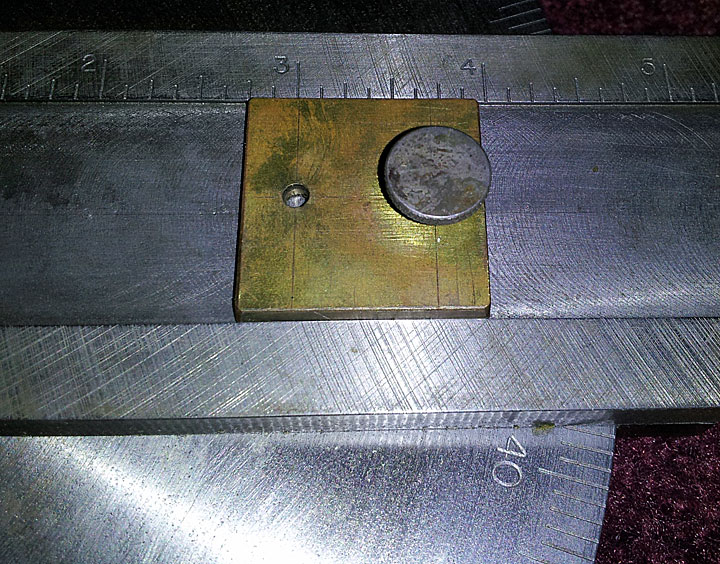

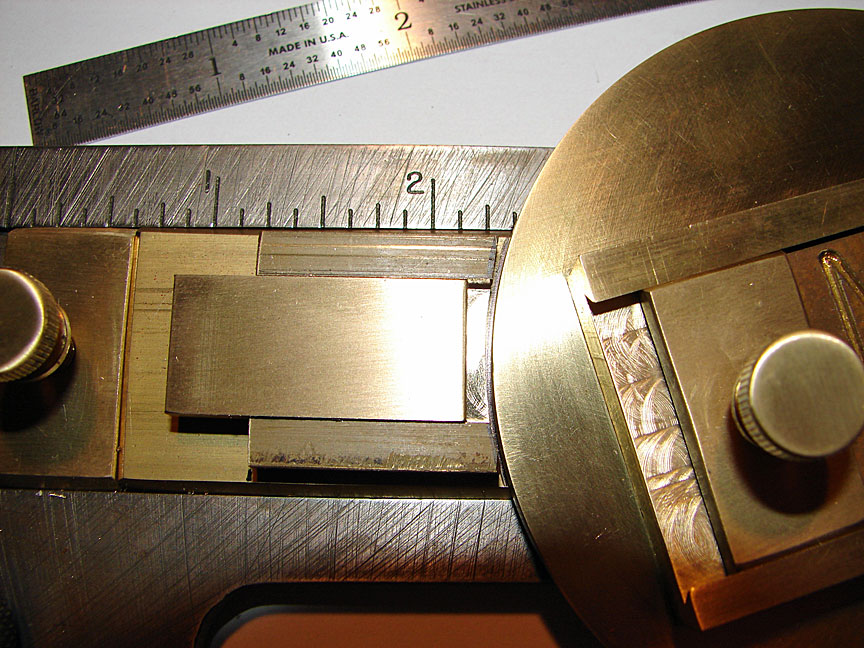

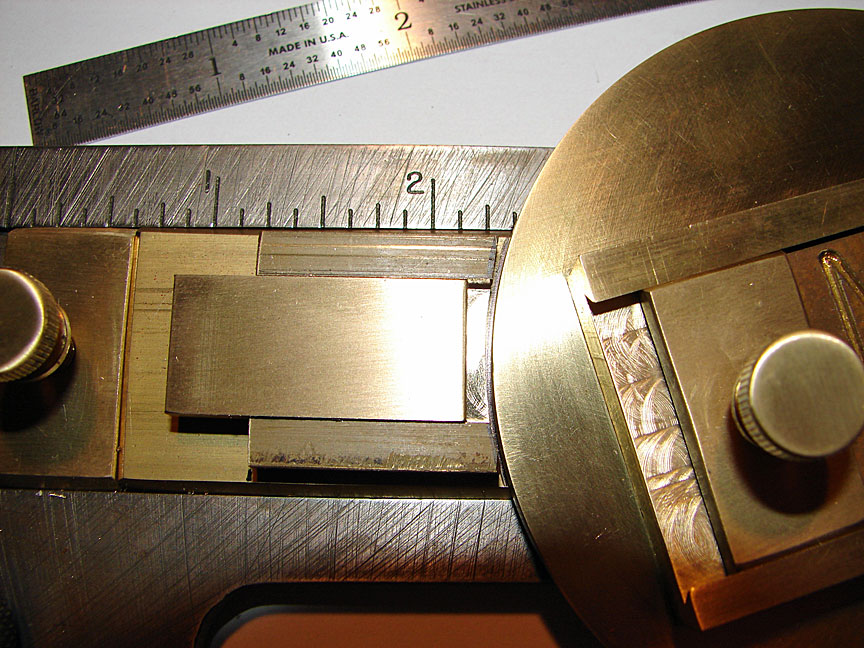

Notice that the dial is marked off in degrees and pivots

around a center point. The two thumb screws at the left can secure

the dial at any desired degree. Half degrees can be clearly estimated.

The long arm is marked off in inches.

The recessed slot on the long arm holds commonly sized

1 1/4" engravers type. In addition, the circle engraving

locking brass fitting can be slid along the arm. The stylus point

can be plugged into the brass fitting and the arm swung around

to engrave circles - even concentric circles.

Notice that the dial is marked off in degrees and pivots

around a center point. The two thumb screws at the left can secure

the dial at any desired degree. Half degrees can be clearly estimated.

The long arm is marked off in inches.

The recessed slot on the long arm holds commonly sized

1 1/4" engravers type. In addition, the circle engraving

locking brass fitting can be slid along the arm. The stylus point

can be plugged into the brass fitting and the arm swung around

to engrave circles - even concentric circles.

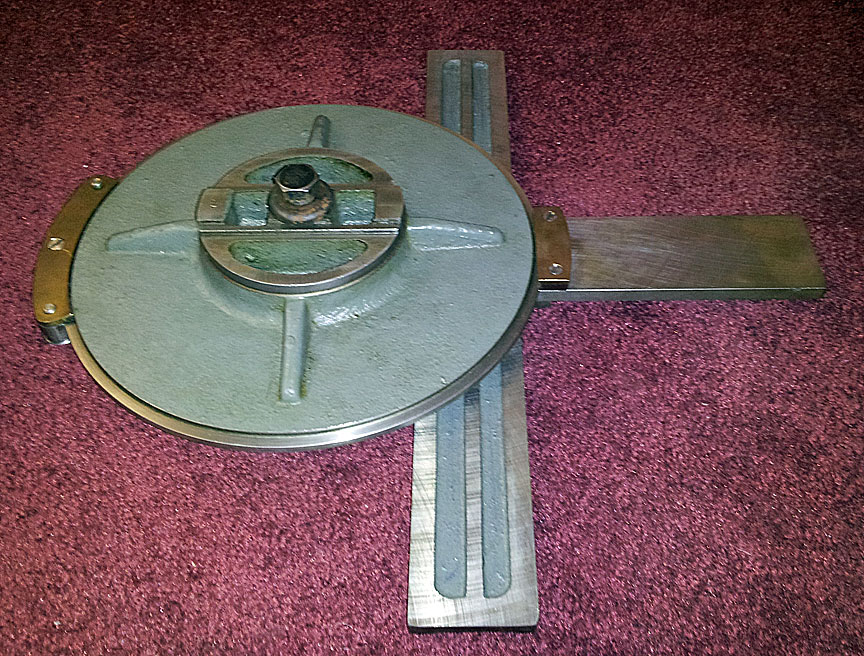

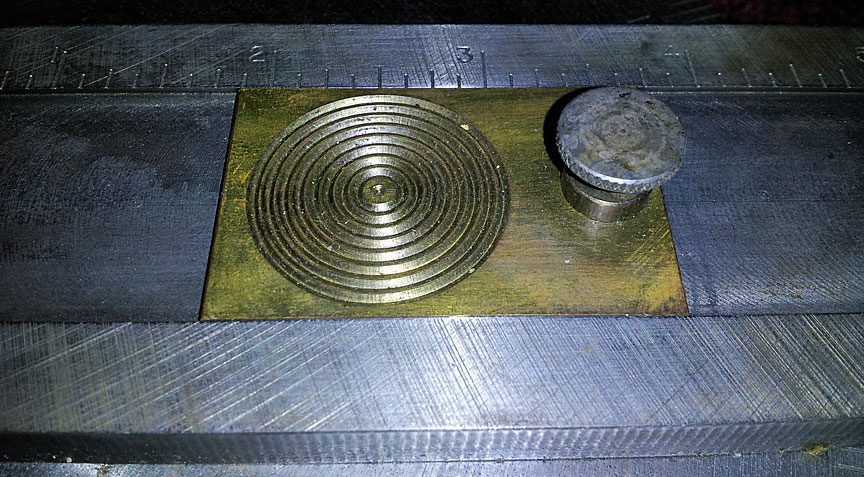

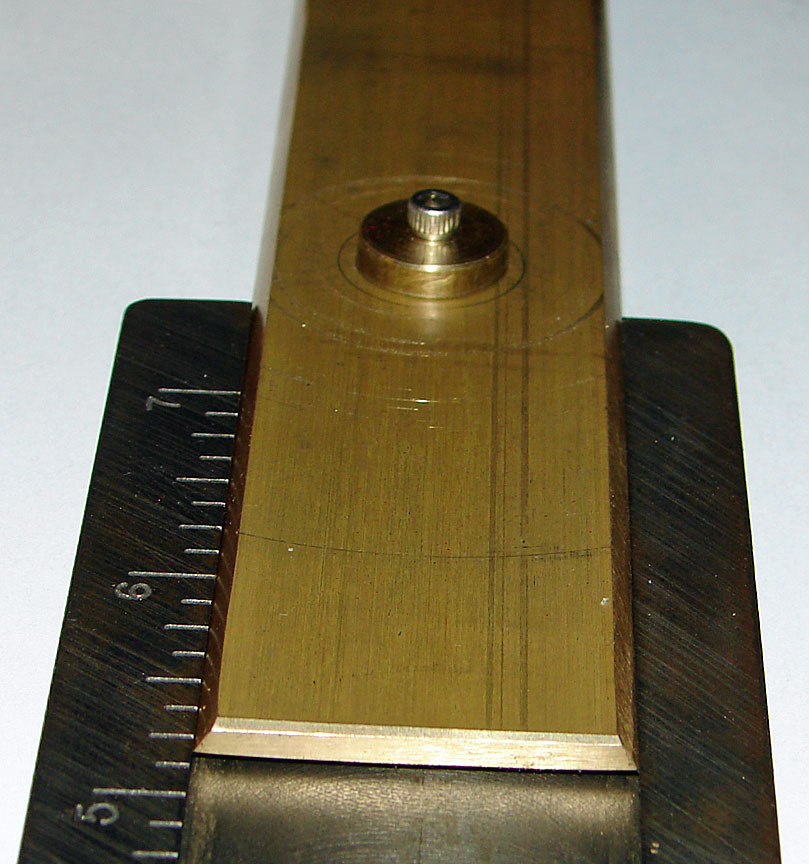

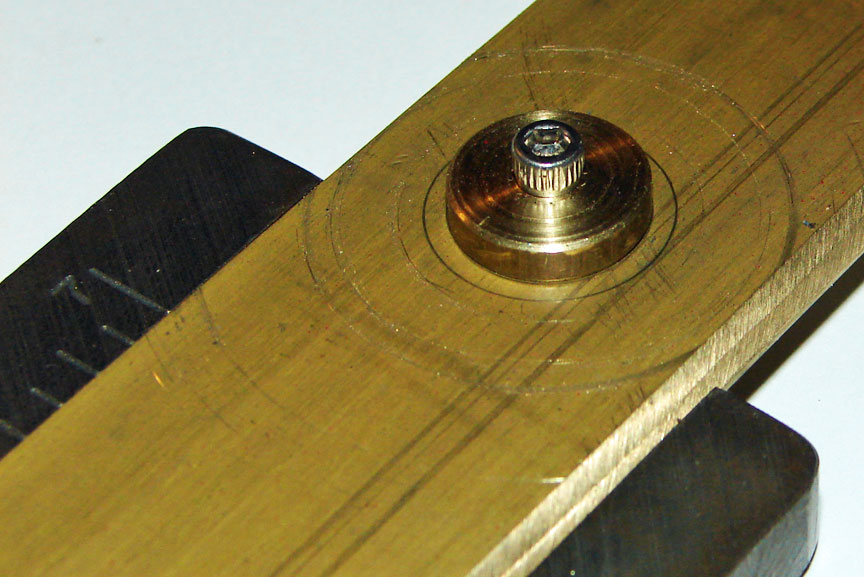

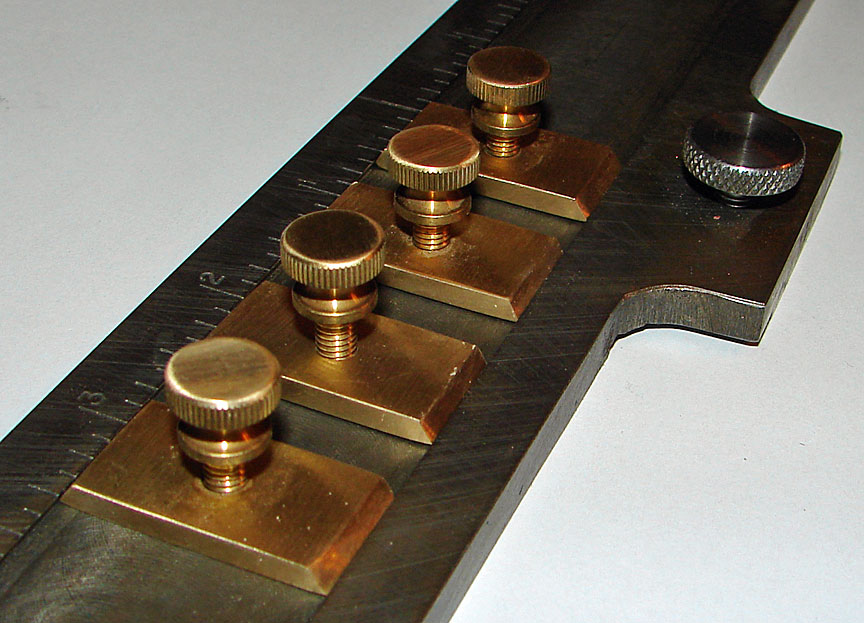

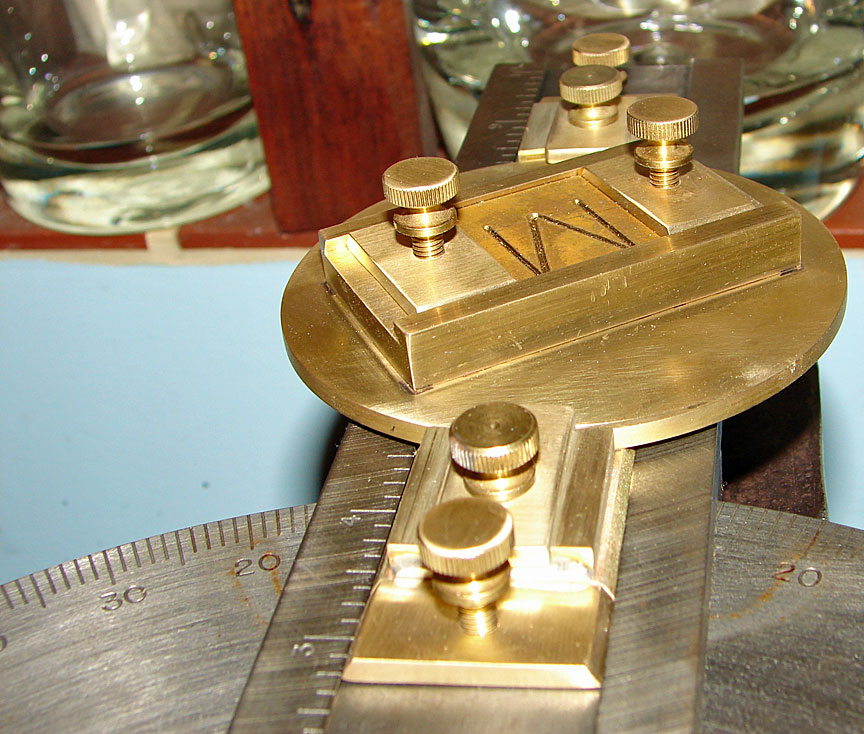

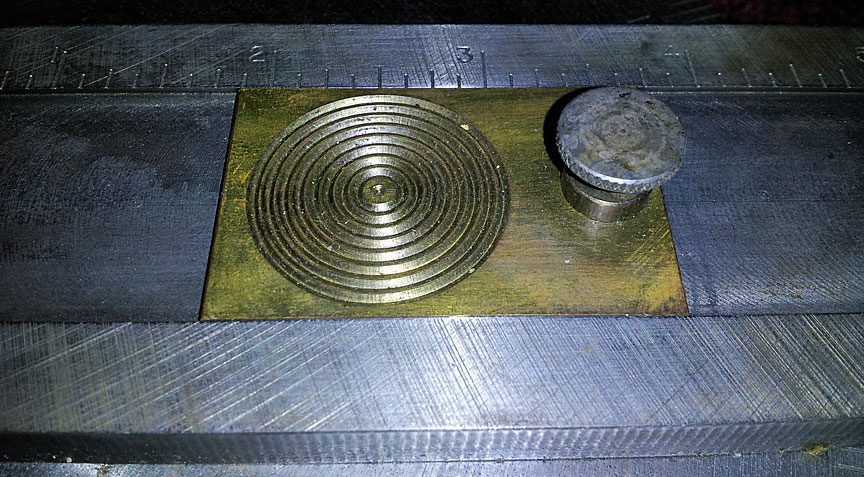

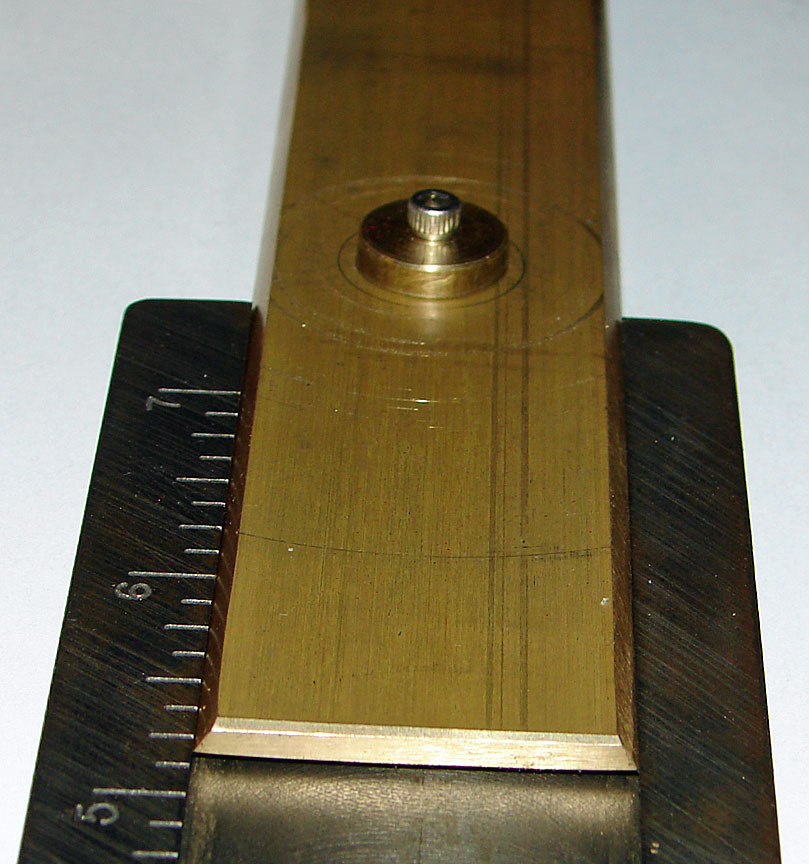

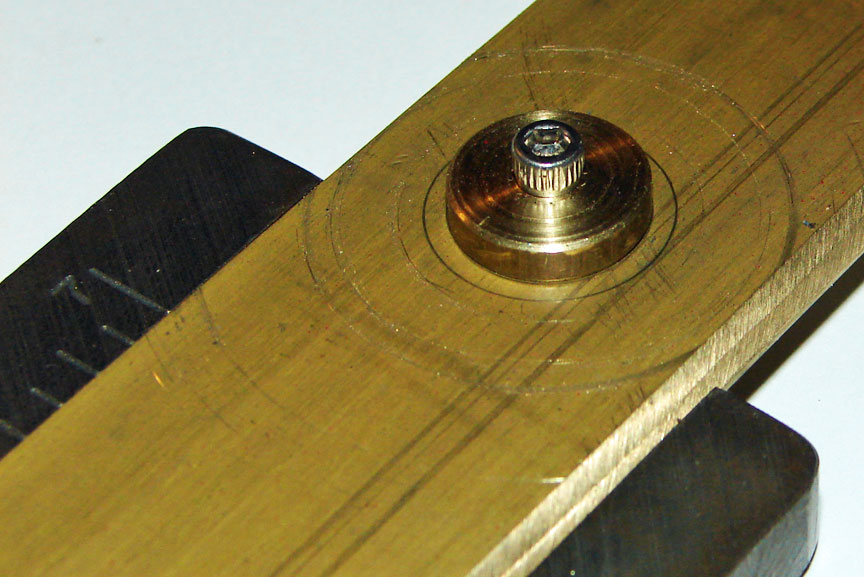

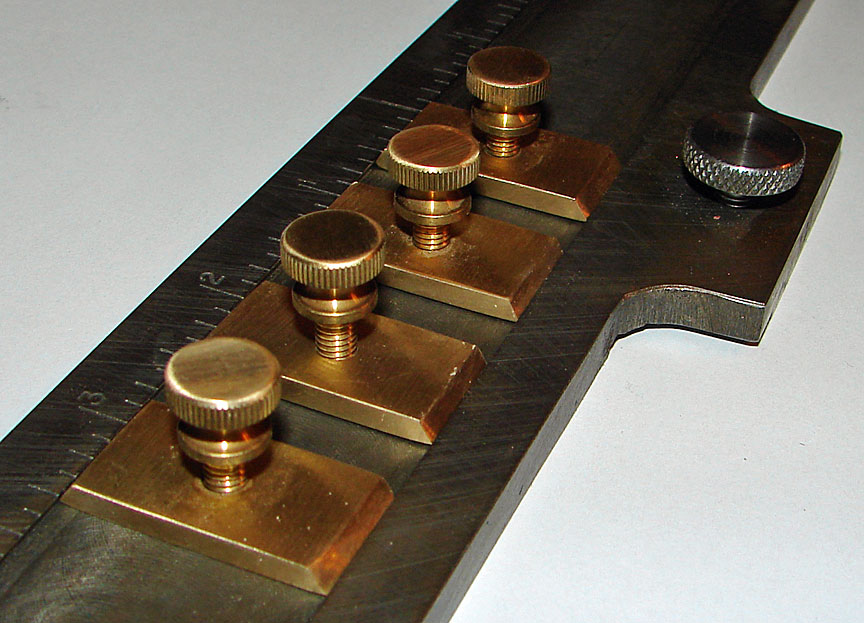

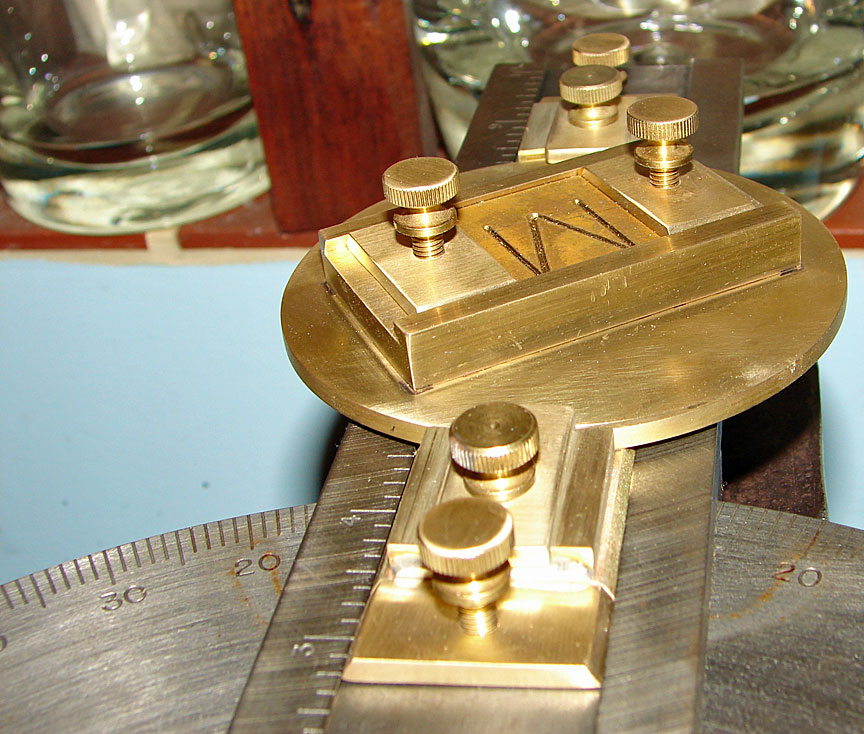

Here is a close up of this brass fitting.

Here is a close up of this brass fitting.

Notice the degree markings shown in the picture above.

These are engraved using a slotting fitting which can be positioned

anywhere along the arm. It locks into position.

Notice the degree markings shown in the picture above.

These are engraved using a slotting fitting which can be positioned

anywhere along the arm. It locks into position.

This slotting fitting has a small pivoting arm which

allows long or short markings to be engraved. This pivoting arm

is in the "short" position in the picture below.

This slotting fitting has a small pivoting arm which

allows long or short markings to be engraved. This pivoting arm

is in the "short" position in the picture below.

Below is the "long" position for the arm

- exposing more slot for the stylus.

Below is the "long" position for the arm

- exposing more slot for the stylus.

Sometimes on engravings small circles are desired.

This brass fitting allows this to be quickly done.

Sometimes on engravings small circles are desired.

This brass fitting allows this to be quickly done.

It should be remembered that the pantograph allows

scaling all of the above to the task at hand.

To make things even more interesting, a cross arm also

attaches to the pivoting long arm. Engravers type fonts fit into

this cross arm. This cross arm will allow engraving the degree

markings in the correct orientation to the degree marking lines.

Words may similarly be engraved at any desired angle.

It should be remembered that the pantograph allows

scaling all of the above to the task at hand.

To make things even more interesting, a cross arm also

attaches to the pivoting long arm. Engravers type fonts fit into

this cross arm. This cross arm will allow engraving the degree

markings in the correct orientation to the degree marking lines.

Words may similarly be engraved at any desired angle.

Both arms are marked off in inches for centering type.

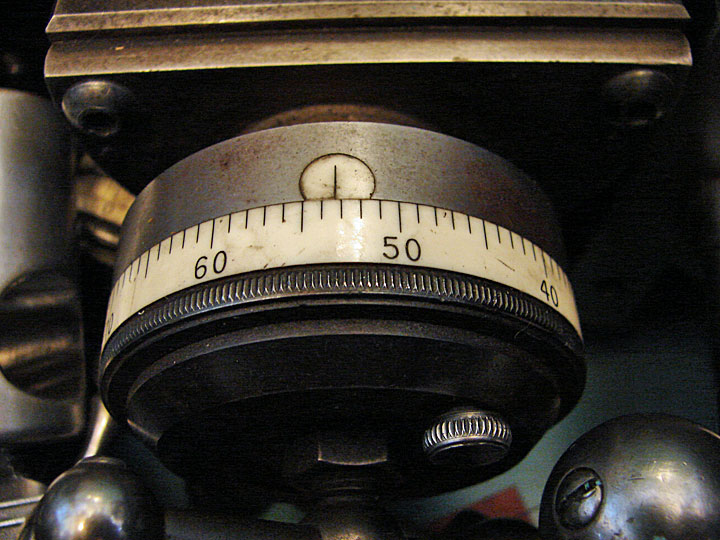

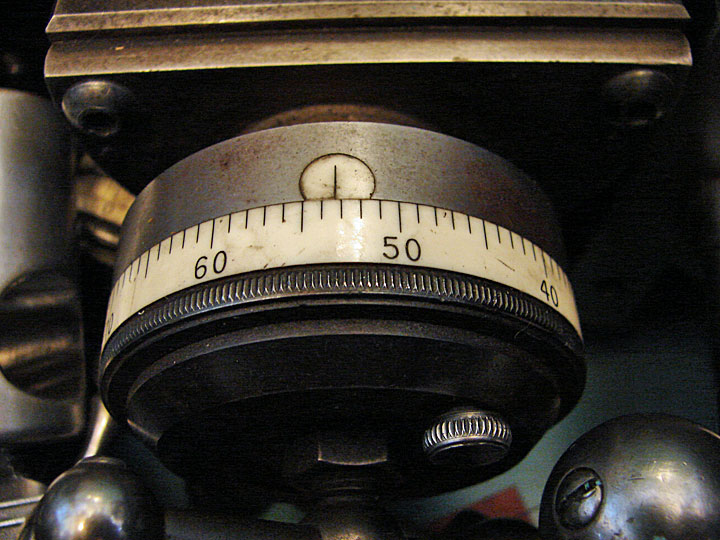

Below is a close up of the degree indicator and locking

thumb screws.

Both arms are marked off in inches for centering type.

Below is a close up of the degree indicator and locking

thumb screws.

This accessory will come in handy for several upcoming

projects. The first project will be to make new dials on an old

Elgin lathe that I have rebuilt and use quite often.

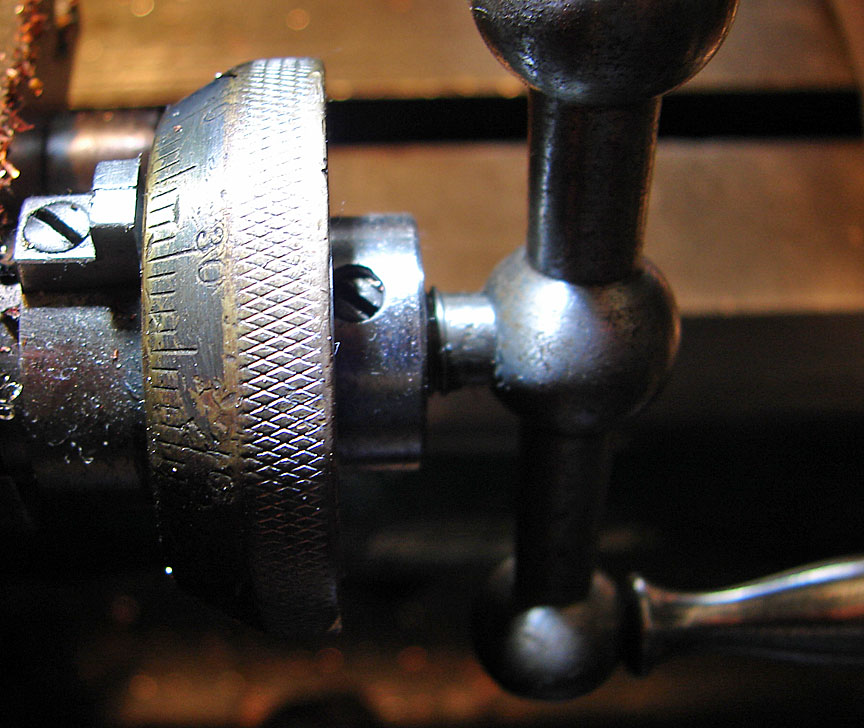

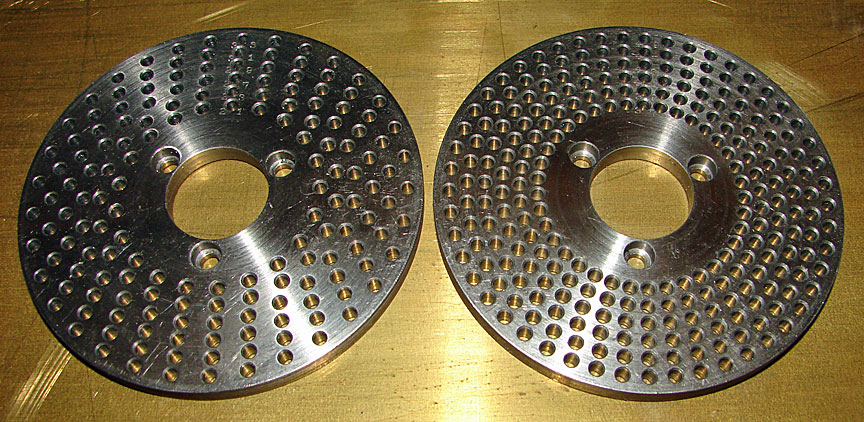

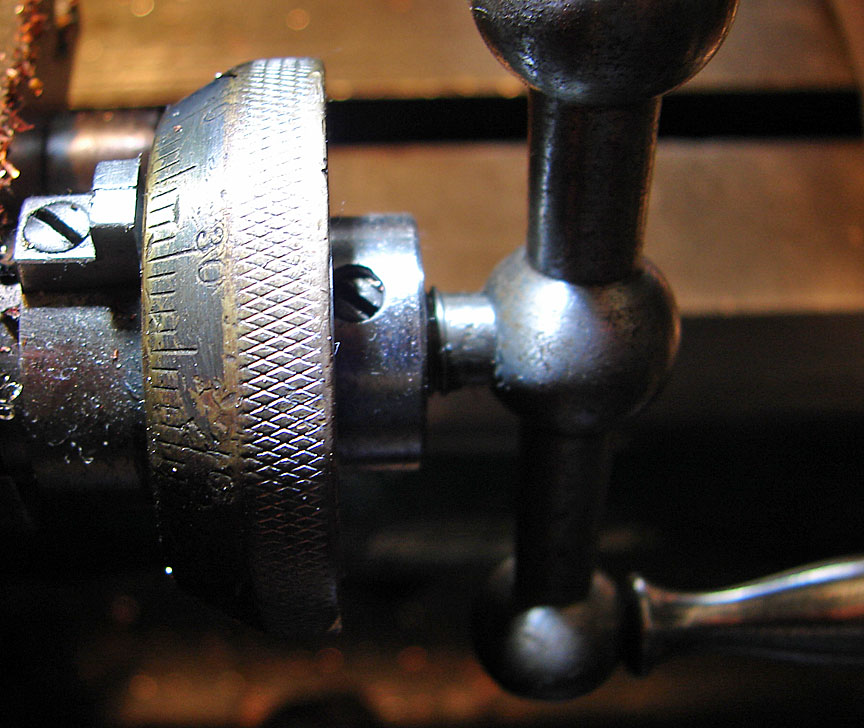

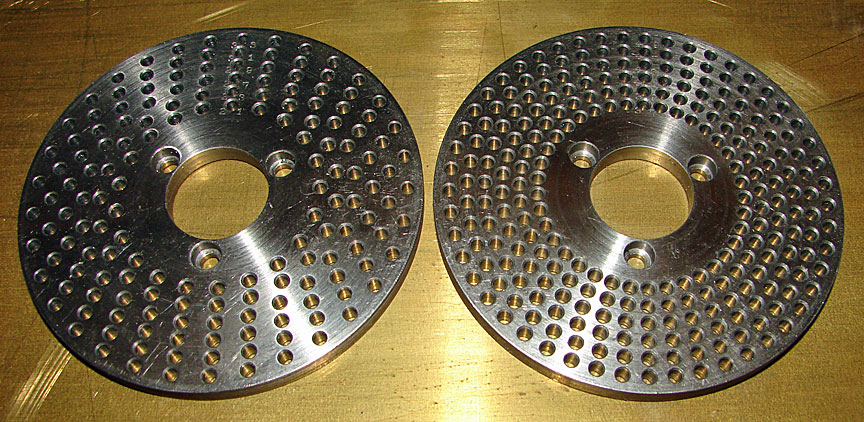

Here are the dials that I will be replacing.

This accessory will come in handy for several upcoming

projects. The first project will be to make new dials on an old

Elgin lathe that I have rebuilt and use quite often.

Here are the dials that I will be replacing.

They are too difficult for my old eyes to quickly read.

The new dials will be of white acetal and resemble the Hardinge

style as seen on another of my lathes. Notice how much easier

these dials are to read.

They are too difficult for my old eyes to quickly read.

The new dials will be of white acetal and resemble the Hardinge

style as seen on another of my lathes. Notice how much easier

these dials are to read.

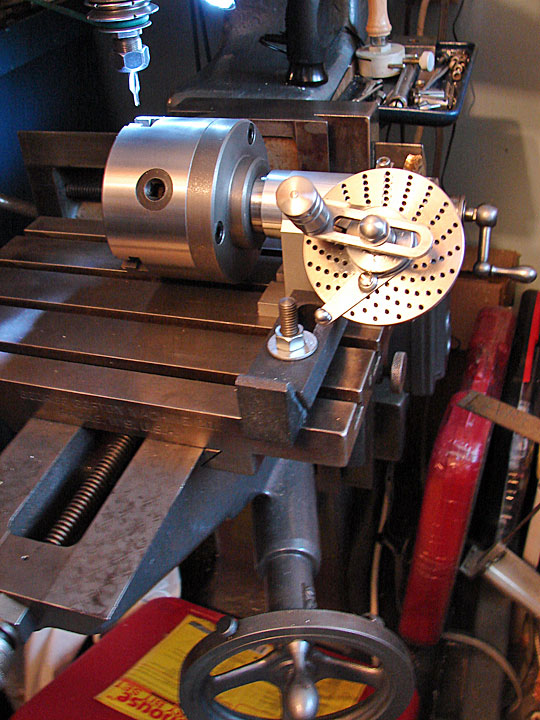

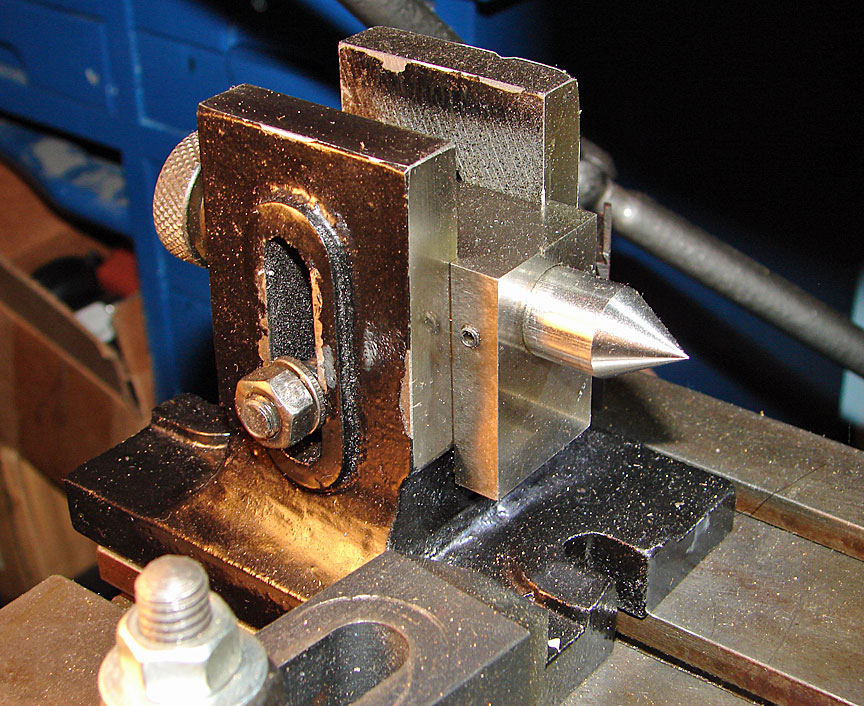

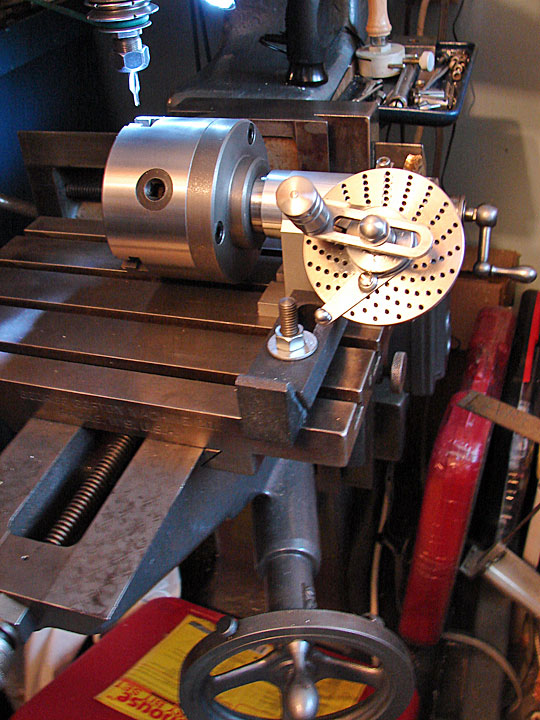

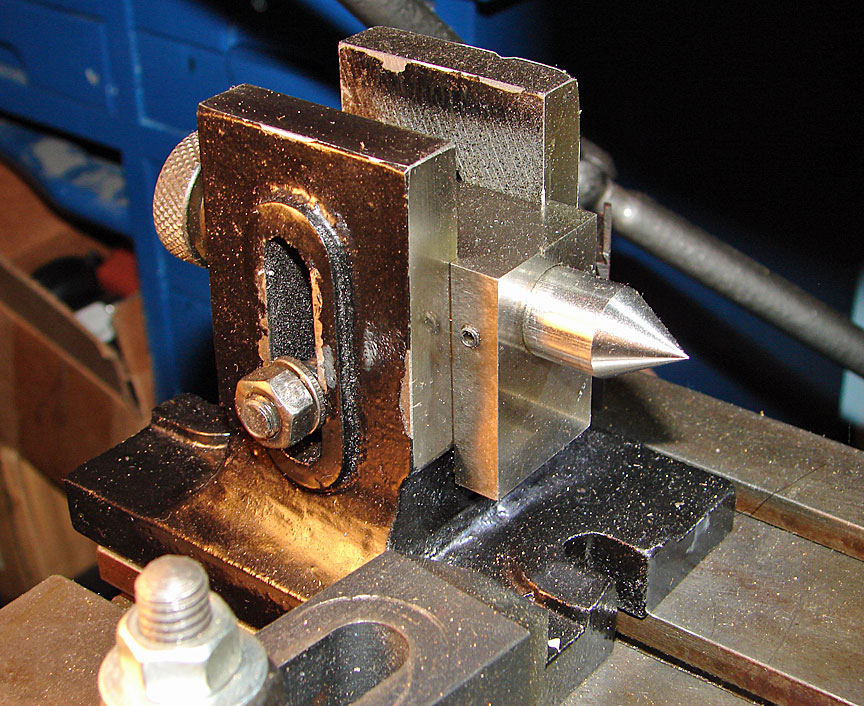

To assist in engraving the new dials will be this dividing

or index head.

To assist in engraving the new dials will be this dividing

or index head.

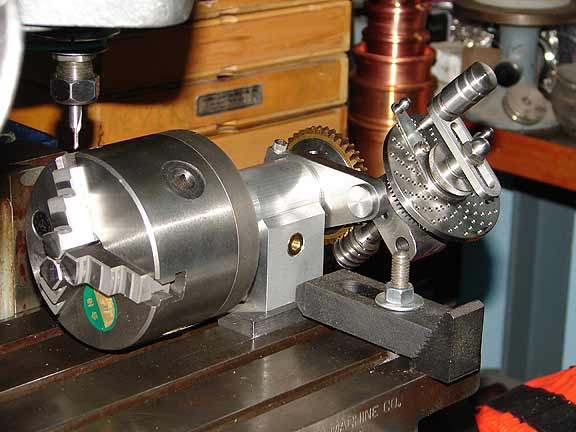

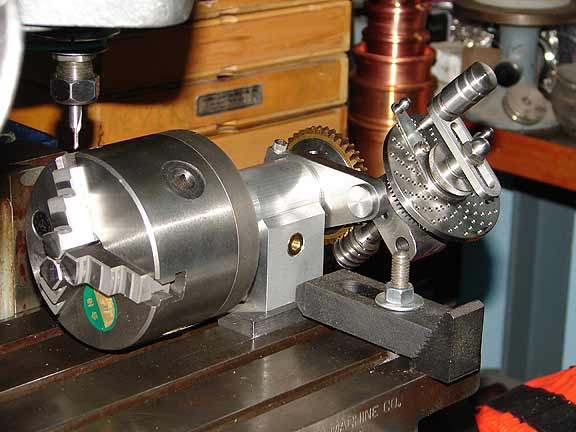

Another view.

Another view.

I just clamped it down for this photo. In use, the

dividing head slides clear over to the table edge and the tailstock

support gets mounted at the other end on the pantograph table.

Everything gets centered. The dial to be engraved is mounted on

an arbor which gets chucked securely. The free arbor end is supported

by the tailstock.

I do have the other two indexing circles to use as

required for the task at hand.

I just clamped it down for this photo. In use, the

dividing head slides clear over to the table edge and the tailstock

support gets mounted at the other end on the pantograph table.

Everything gets centered. The dial to be engraved is mounted on

an arbor which gets chucked securely. The free arbor end is supported

by the tailstock.

I do have the other two indexing circles to use as

required for the task at hand.

Below is a picture of the tailstock which supports

the arbor end.

Below is a picture of the tailstock which supports

the arbor end.

The new dial engraving accessory has been installed

onto my Gorton 3U.

The new dial engraving accessory has been installed

onto my Gorton 3U.

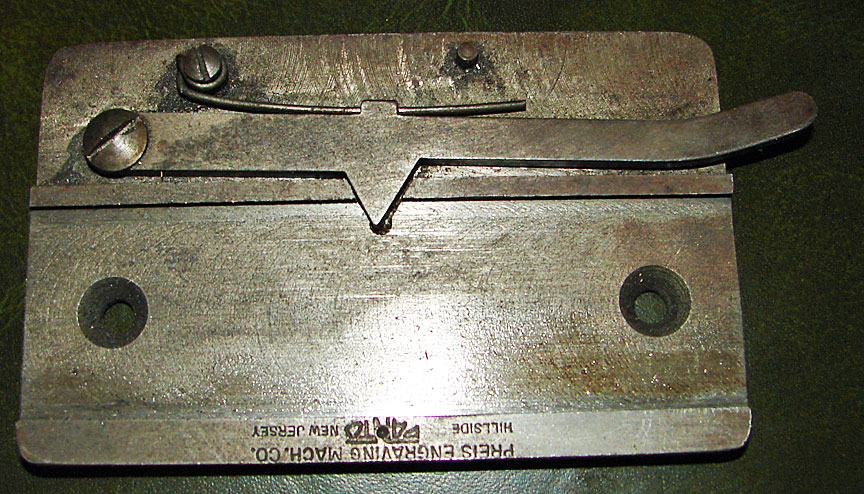

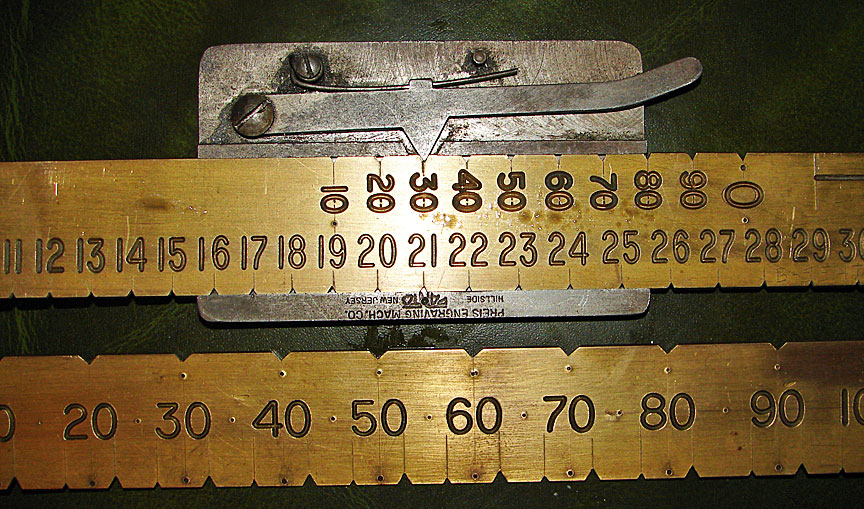

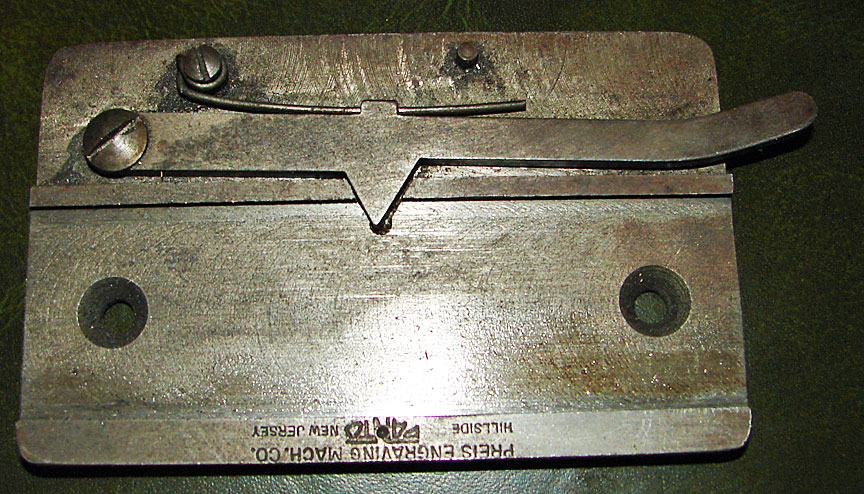

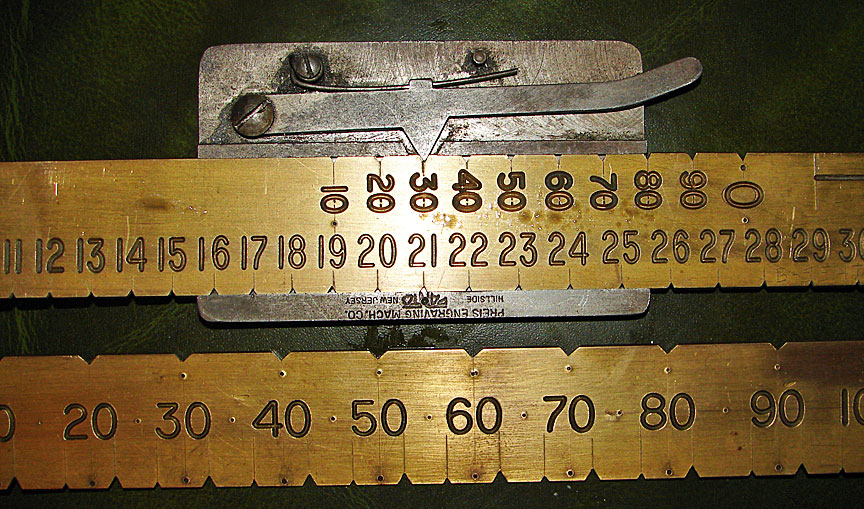

The Preis company had a nice solution to engraving

the numbers onto a dial. This is the locking positioning attachment

which gets screwed to a copy table.

The Preis company had a nice solution to engraving

the numbers onto a dial. This is the locking positioning attachment

which gets screwed to a copy table.

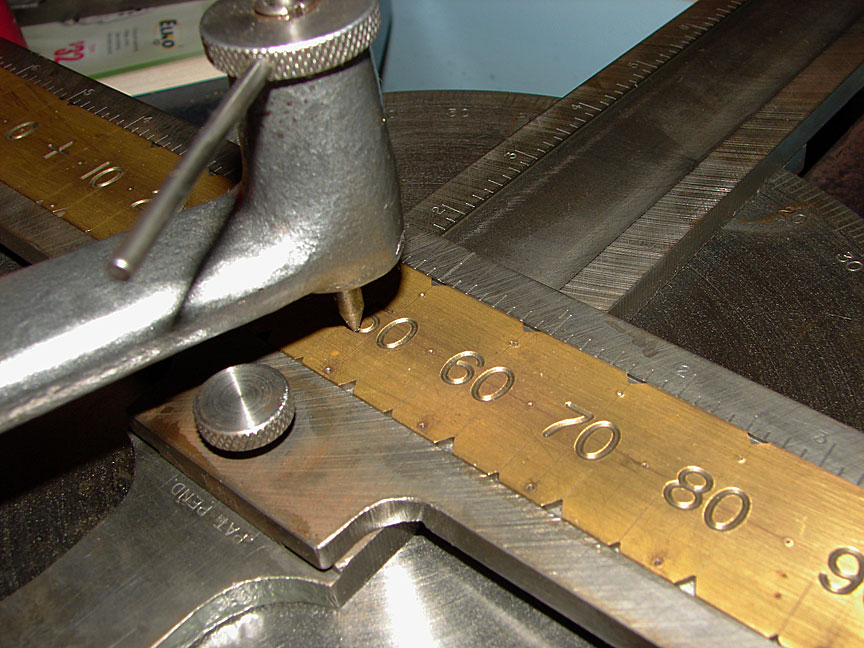

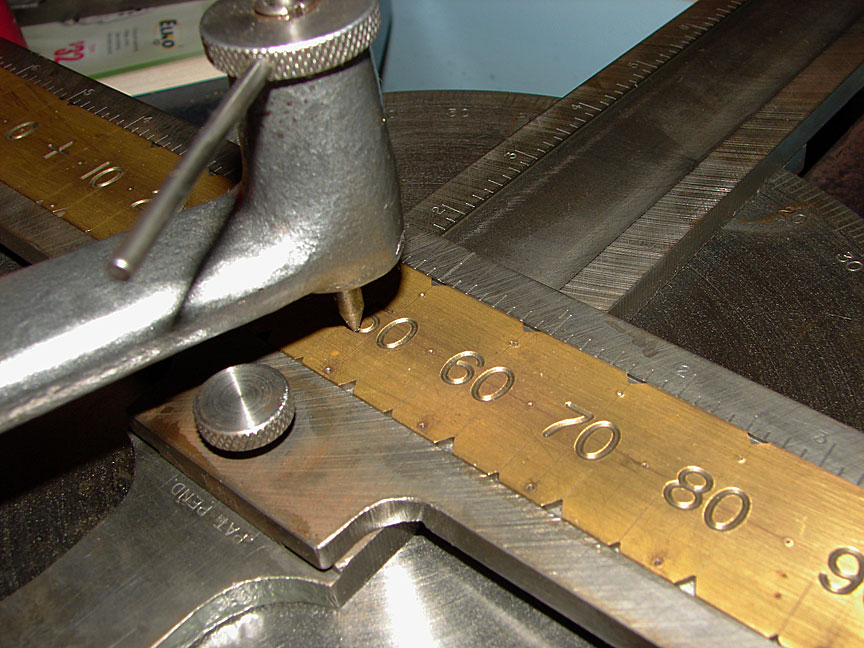

In use, notched copy strips were slid along their length

and locked into position as needed. Shown are two differently

oriented notched copy strips along with the Preis positioning

attachment. This is a nice system. Barely seen at the very right

of the below photo is part of a slot for making the degree markings.

There are both long and short slots on these numbr strips.

In use, notched copy strips were slid along their length

and locked into position as needed. Shown are two differently

oriented notched copy strips along with the Preis positioning

attachment. This is a nice system. Barely seen at the very right

of the below photo is part of a slot for making the degree markings.

There are both long and short slots on these numbr strips.

Alternately these copy strips may be used directly

with the dial engraving accessory. The "V" notch above

the number to be engraved gets centered on the "0" mark

of the graduated scale. The copy strip gets clamped down during

the engraving.

Alternately these copy strips may be used directly

with the dial engraving accessory. The "V" notch above

the number to be engraved gets centered on the "0" mark

of the graduated scale. The copy strip gets clamped down during

the engraving.

Here are the two quick and easy solutions to getting

numbers on the dials to be engraved. If you look carefully at

the Preis copy strips, you will be able to see the long and short

grooves for engraving the degree lines.

Here are the two quick and easy solutions to getting

numbers on the dials to be engraved. If you look carefully at

the Preis copy strips, you will be able to see the long and short

grooves for engraving the degree lines.

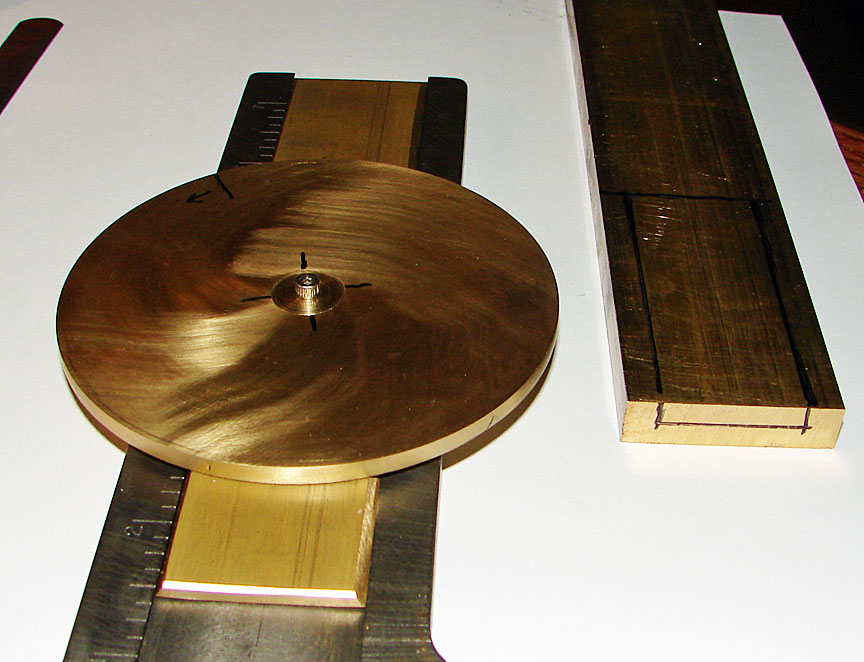

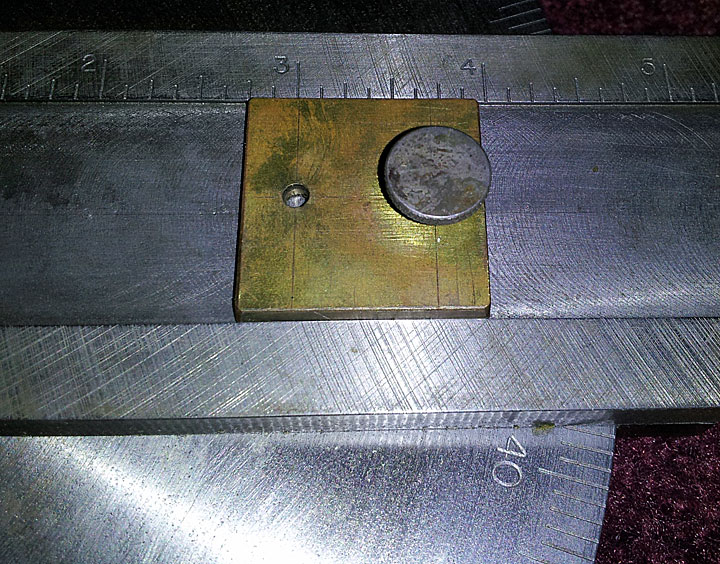

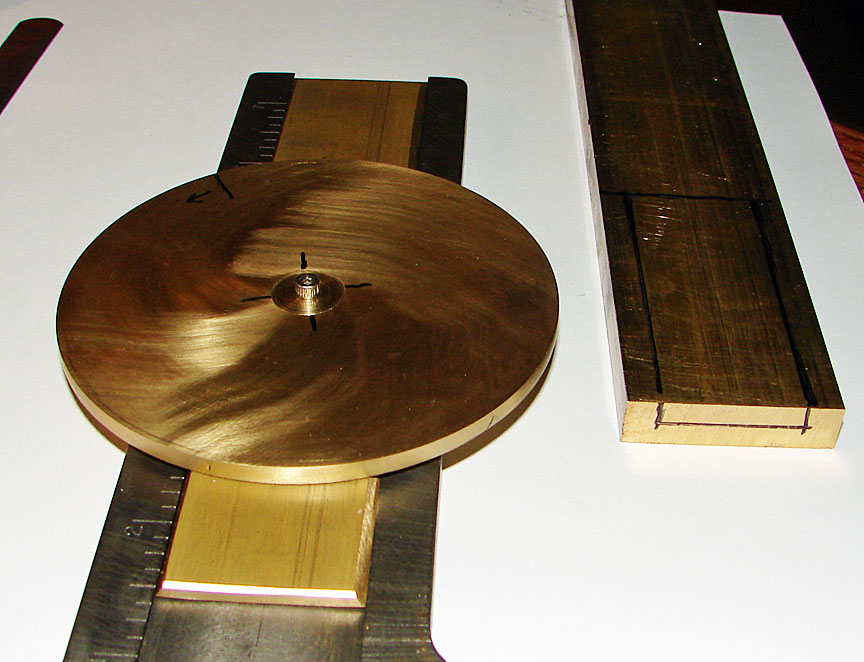

Below will be shown an attachment that I am making

to use with the dial engraving accessary. I will show various

stages of its construction. As it all comes together, things will

become clearer. The first part to be made was the base plate which

is made to slide into any Gorton 1 1/4" copy holder. Also

made was a 1/2" disc which will serve as the axle for the

new attachment.

An 1/8" thick brass disc with a 1/2" center

hole was made. This disc fits onto the 1/2" disc.

To the right in this photo is the rough layut for the

new mini-copy holder for the attachment.This mini-copy holder

will hold standard 1 1/4" type.

An 1/8" thick brass disc with a 1/2" center

hole was made. This disc fits onto the 1/2" disc.

To the right in this photo is the rough layut for the

new mini-copy holder for the attachment.This mini-copy holder

will hold standard 1 1/4" type.

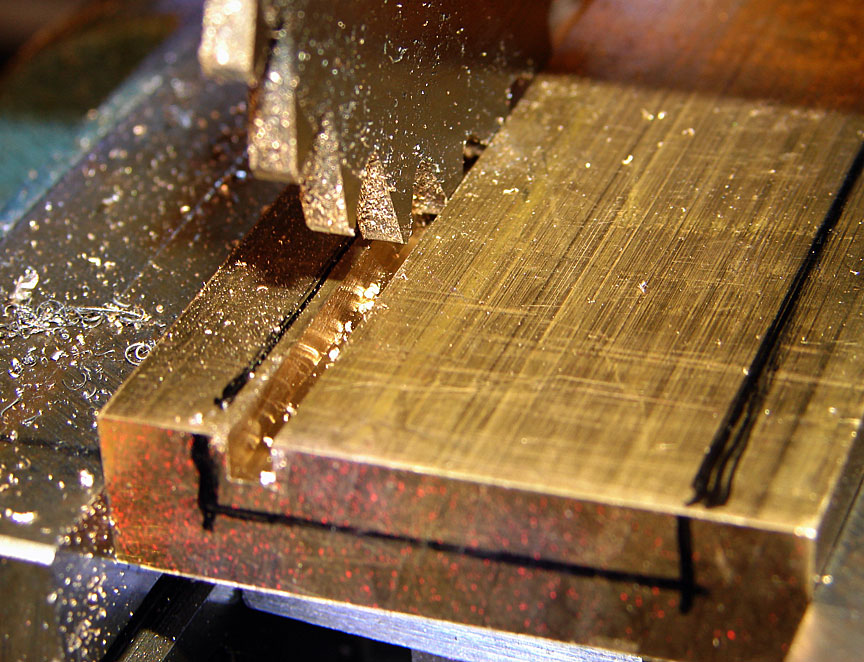

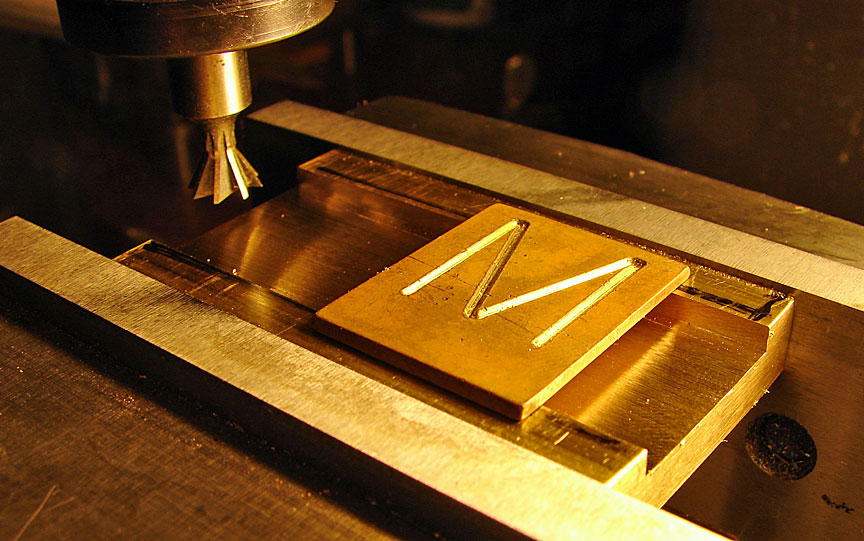

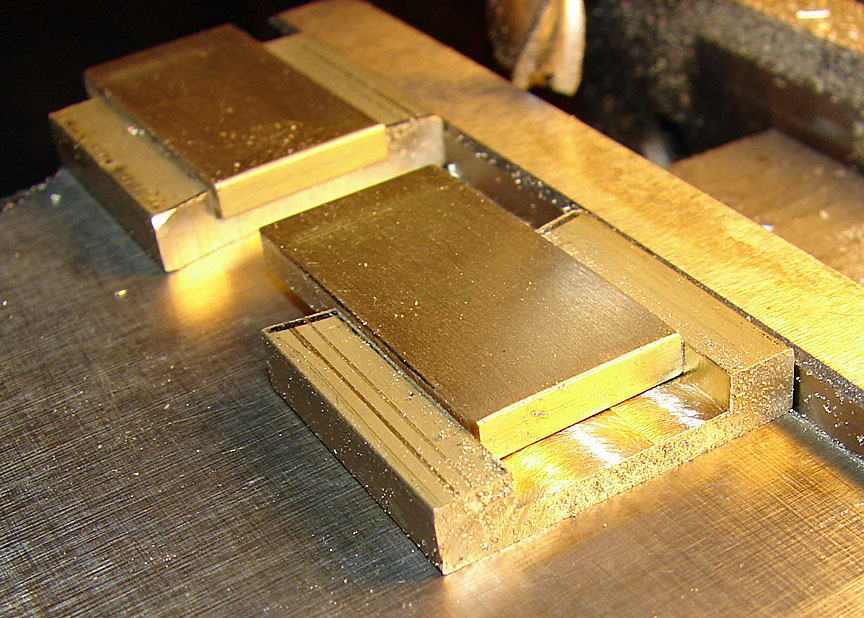

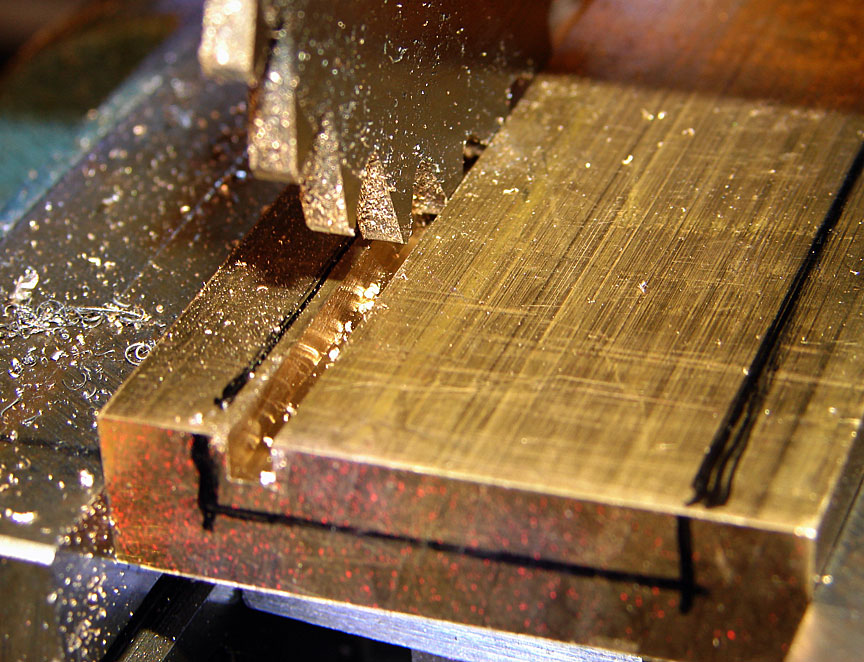

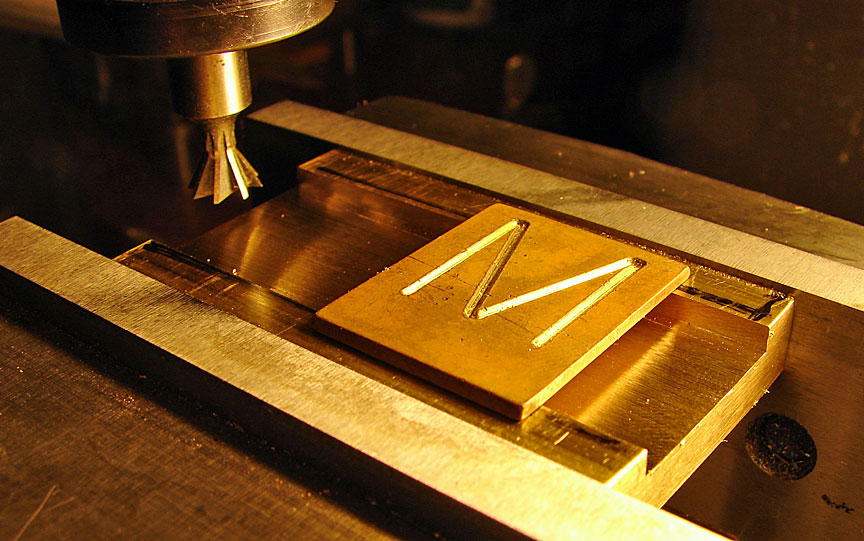

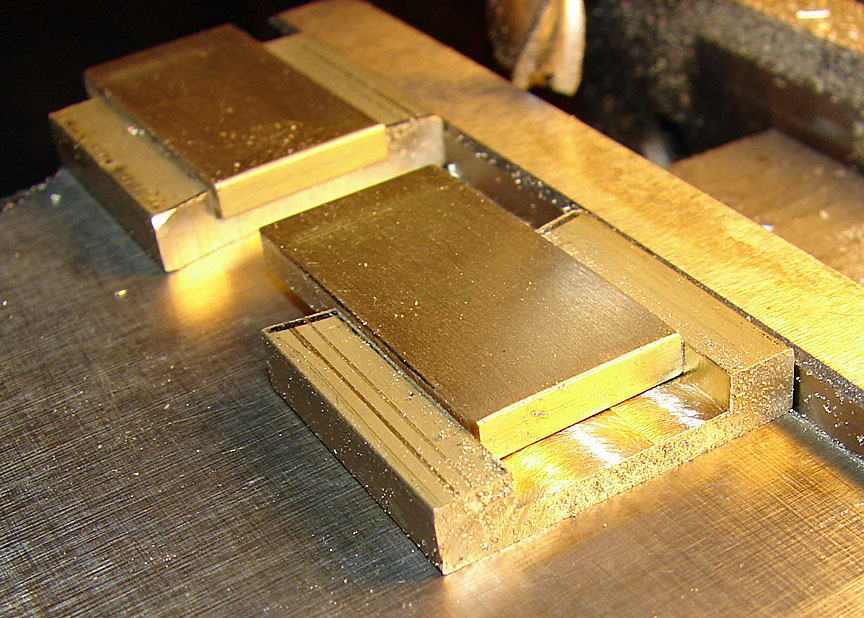

The recess in the mini-copy holder is cut on a horizontal

mill.

Shown here is the first cut.

The recess in the mini-copy holder is cut on a horizontal

mill.

Shown here is the first cut.

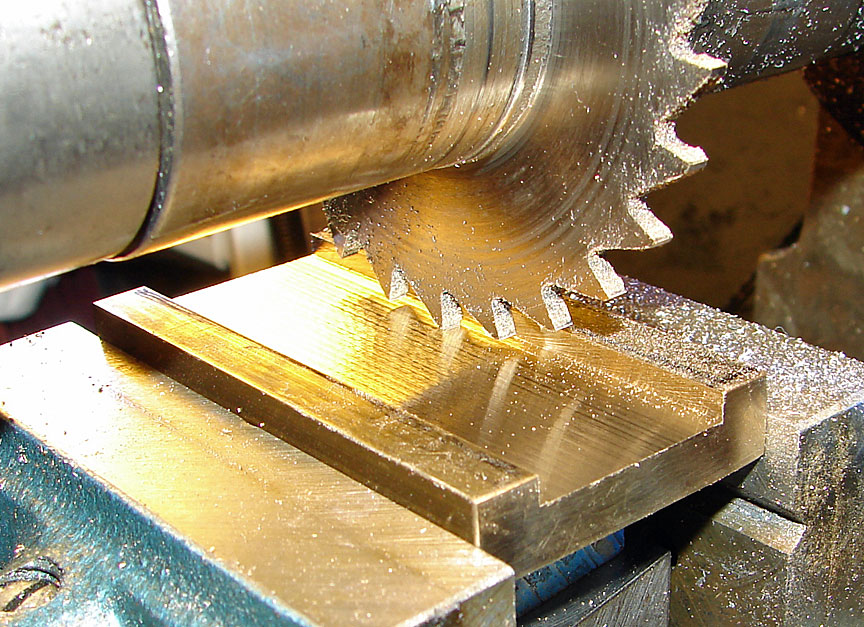

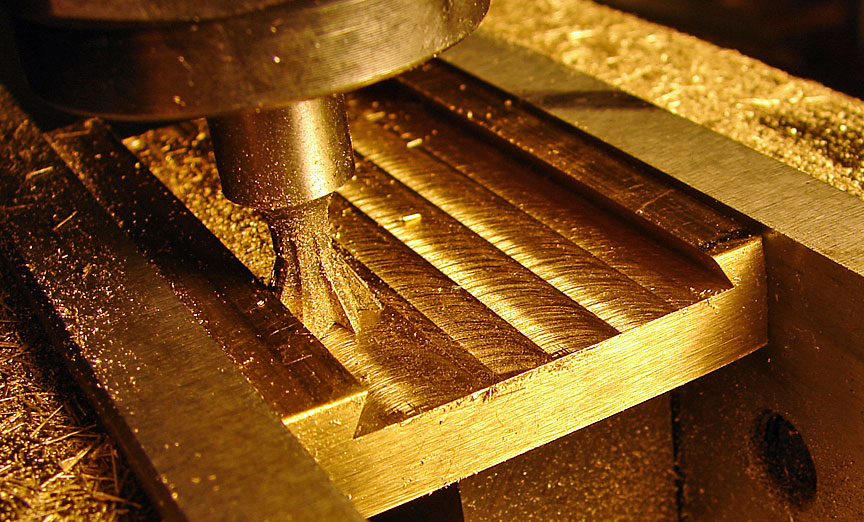

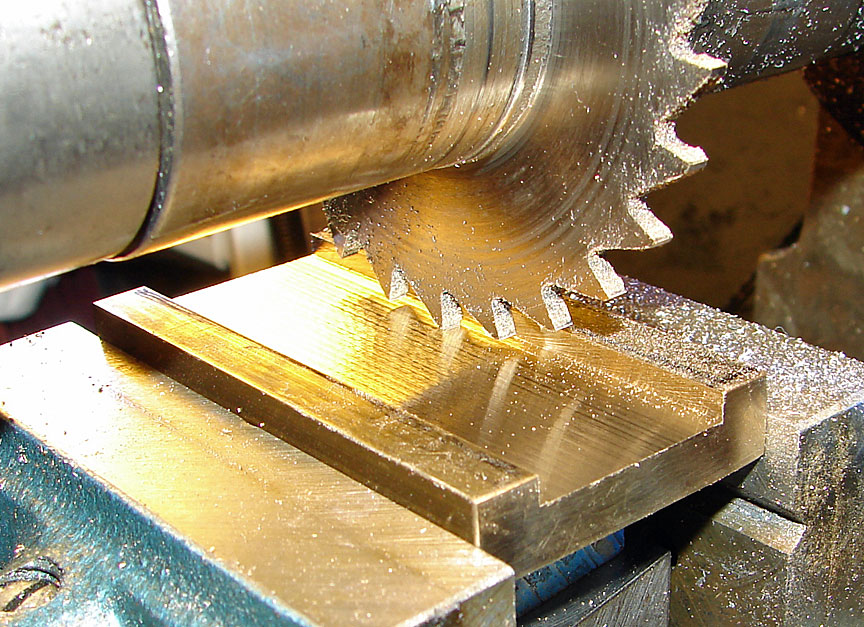

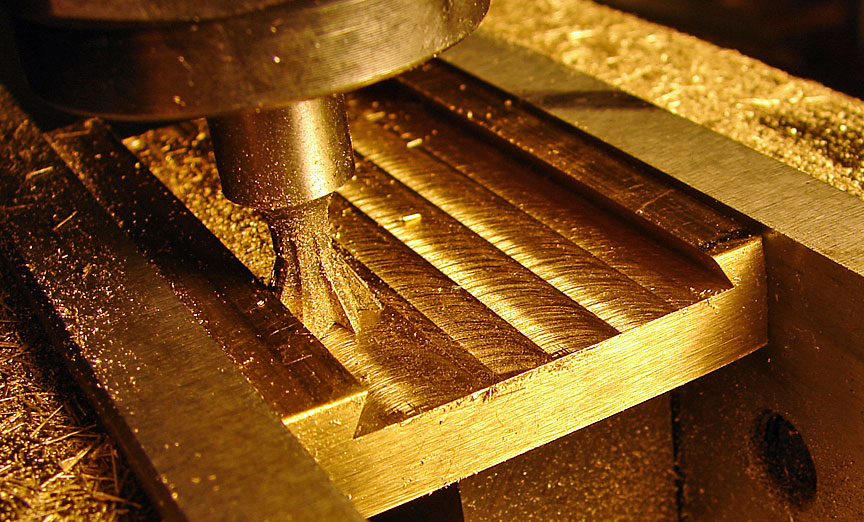

After a series of cuts, the recess looks like this.

After a series of cuts, the recess looks like this.

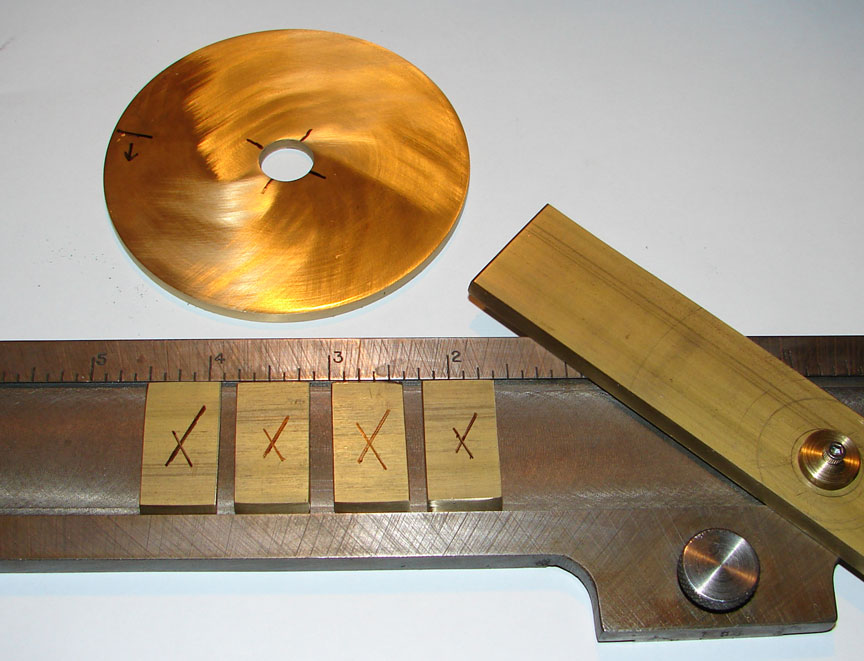

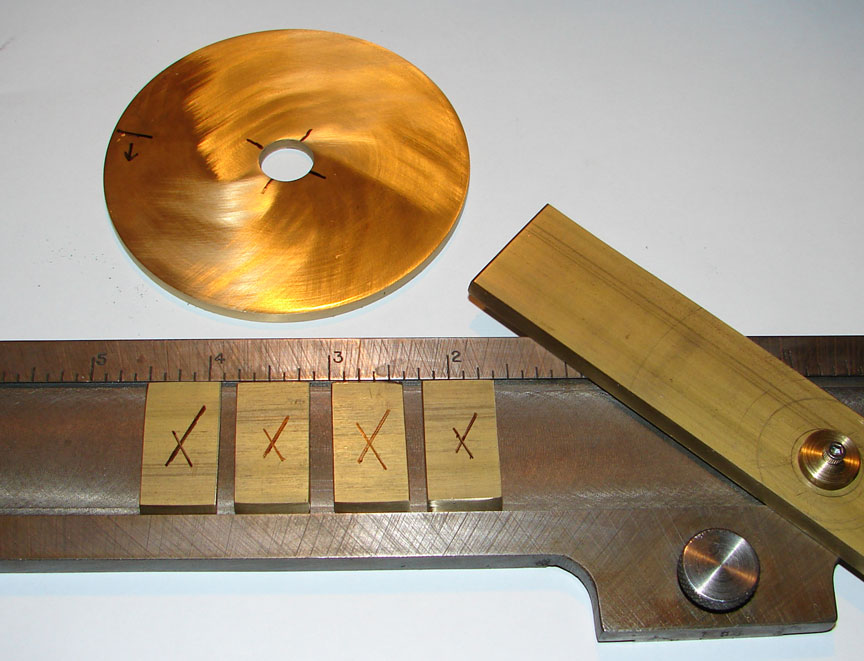

Several type or copy stops needed to be made.

Here are four blank stops marked for center punching,

drilling, and tapping.

Several type or copy stops needed to be made.

Here are four blank stops marked for center punching,

drilling, and tapping.

Shown are the four stops completed. Their use will

soon be apparent.

Shown are the four stops completed. Their use will

soon be apparent.

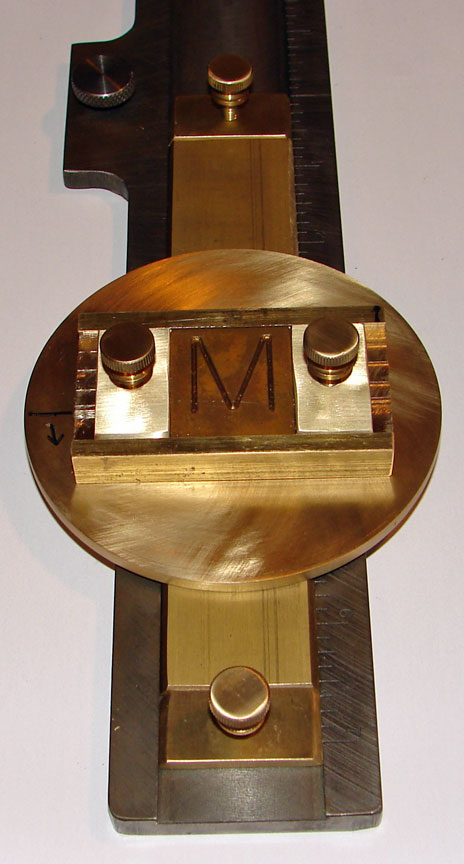

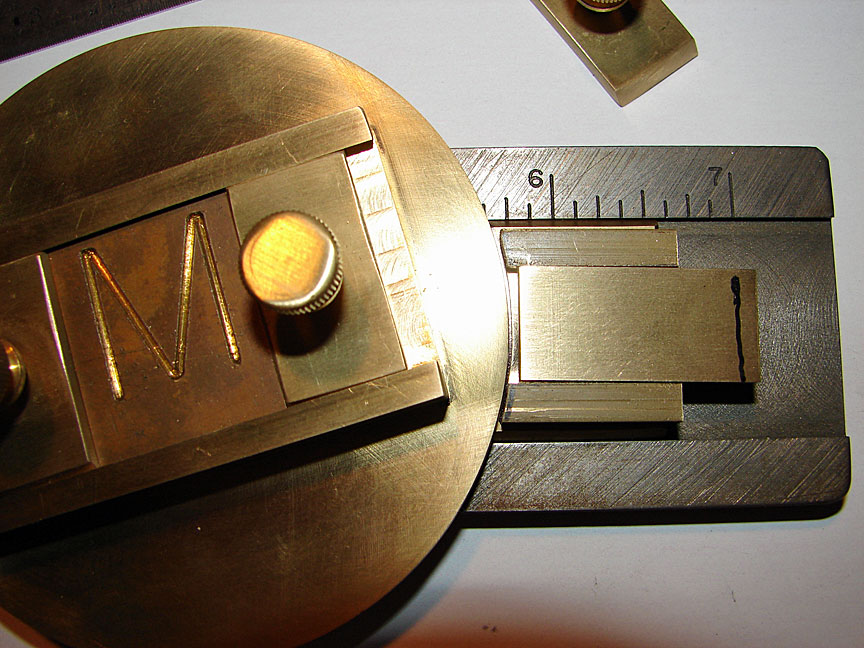

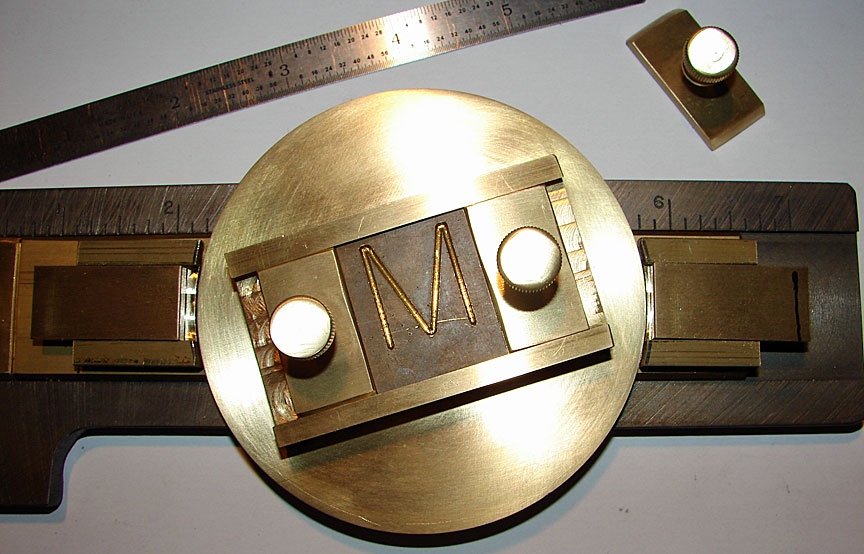

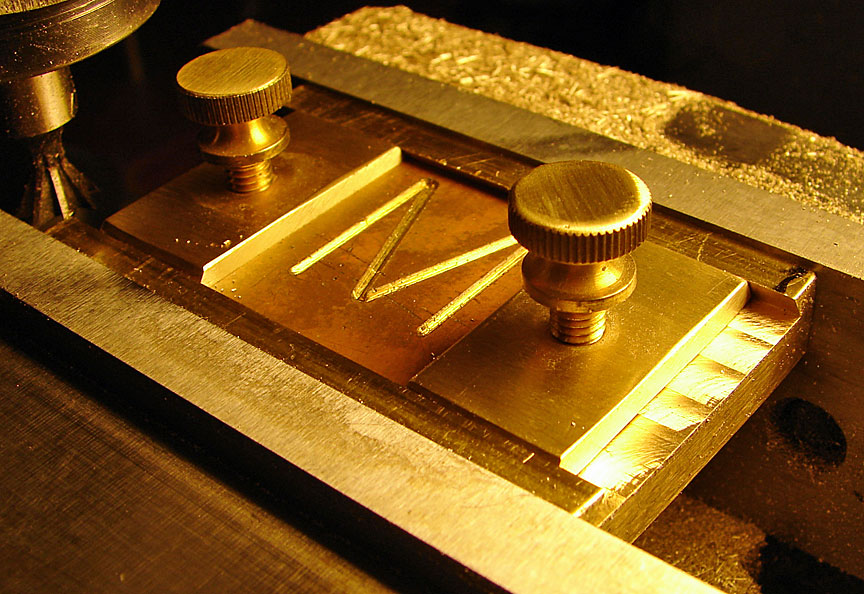

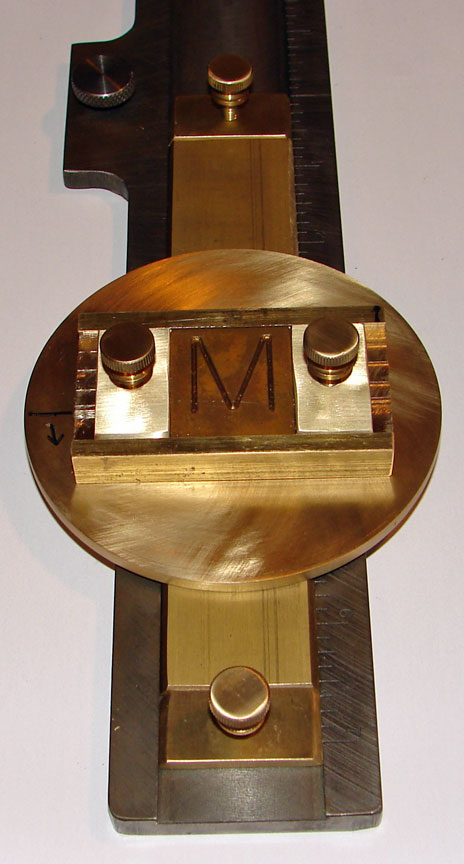

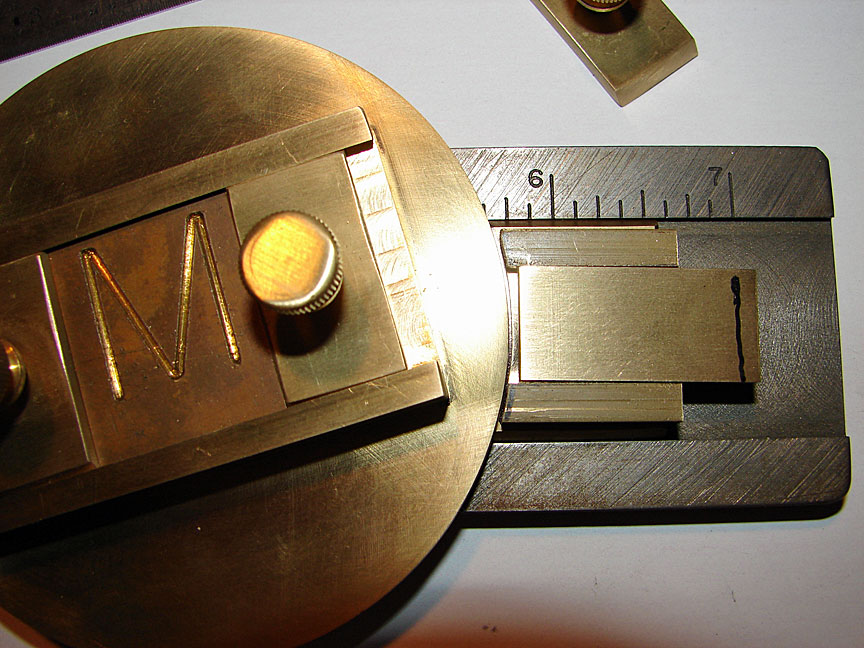

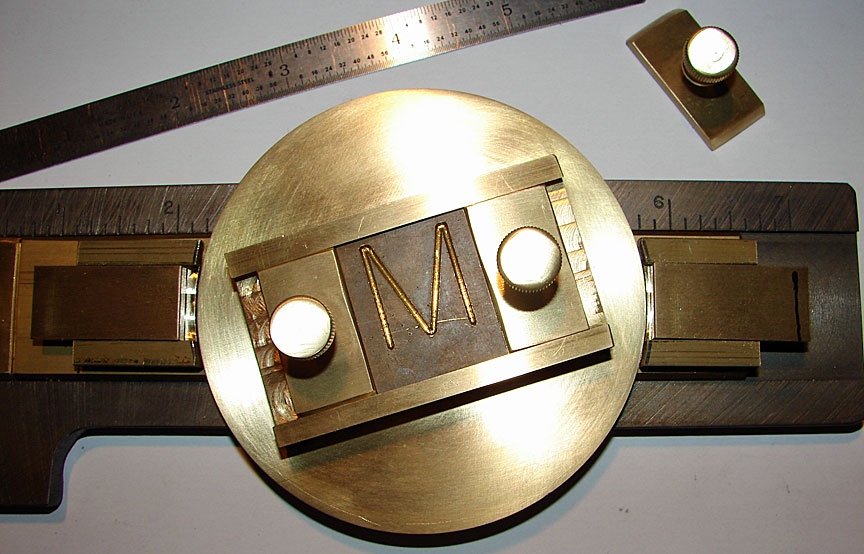

Things are coming together ... a wide letter (M) is

placed on the mini-copy holder for size and dovetail positioning.

Things are coming together ... a wide letter (M) is

placed on the mini-copy holder for size and dovetail positioning.

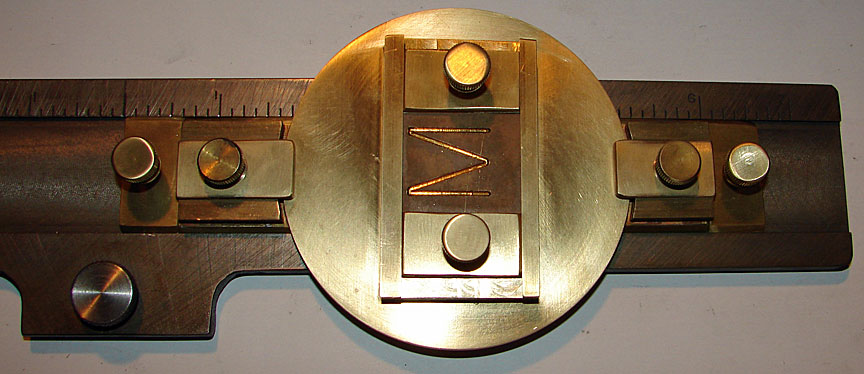

Machining of the dovetails is begun. Notice the sharp

"V" now on both sides of the recess.

Machining of the dovetails is begun. Notice the sharp

"V" now on both sides of the recess.

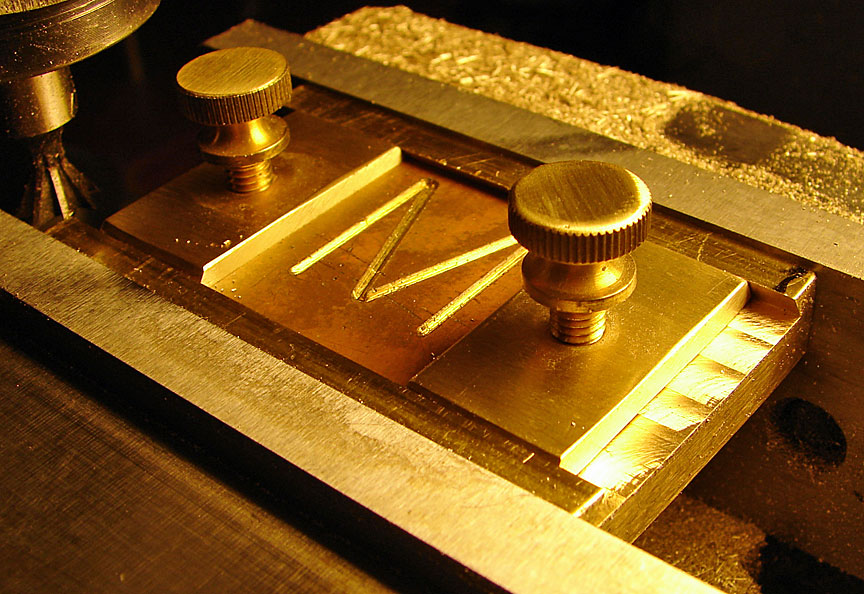

Two of the newly made type locks can secure any letter

or number desired. If necessary, condensed type may be used for

numbers.

Two of the newly made type locks can secure any letter

or number desired. If necessary, condensed type may be used for

numbers.

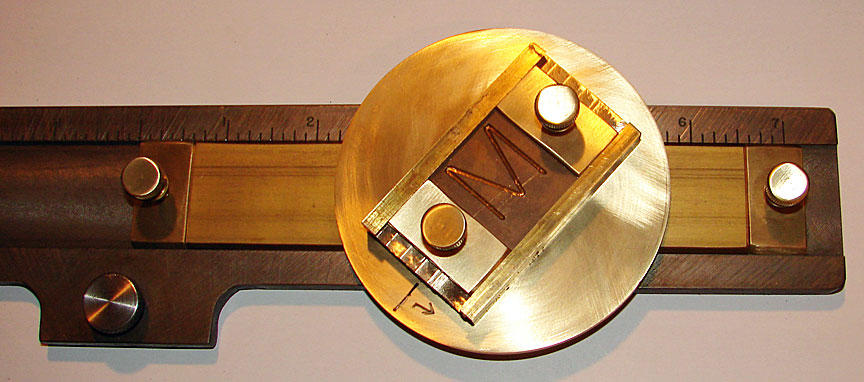

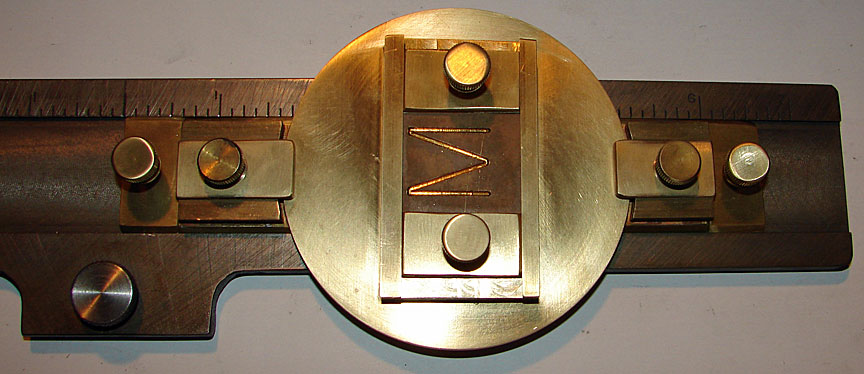

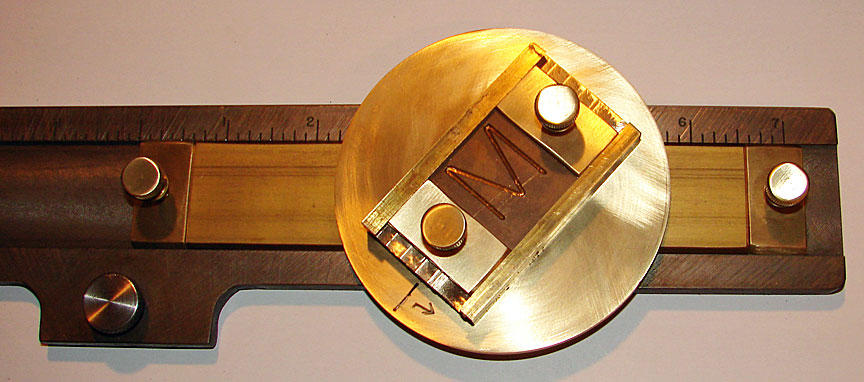

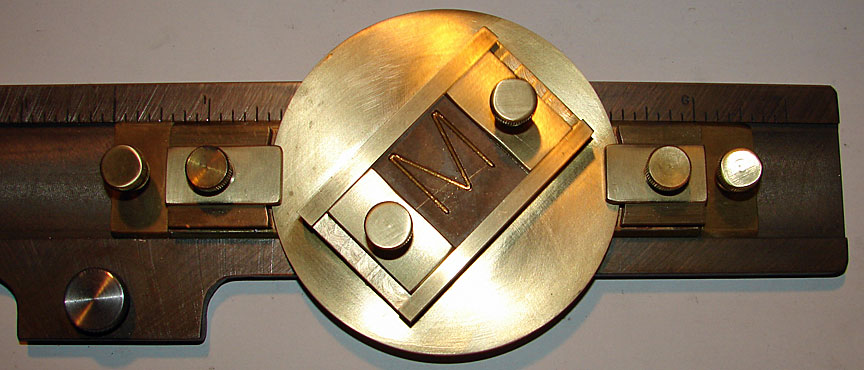

Below parts are partially assembled to demonstrate

what I am making here.

Below parts are partially assembled to demonstrate

what I am making here.

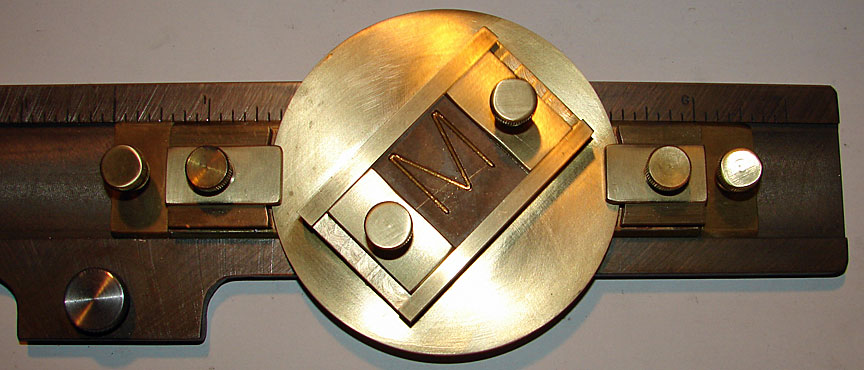

Another view ...

Another view ...

The power of this attachment to the dial engraving

accessory becomes apparent when it is seen that this copy can

be rotated (and soon locked in position). This allows making clock

dials or faces with all of the numbers upright.

The power of this attachment to the dial engraving

accessory becomes apparent when it is seen that this copy can

be rotated (and soon locked in position). This allows making clock

dials or faces with all of the numbers upright.

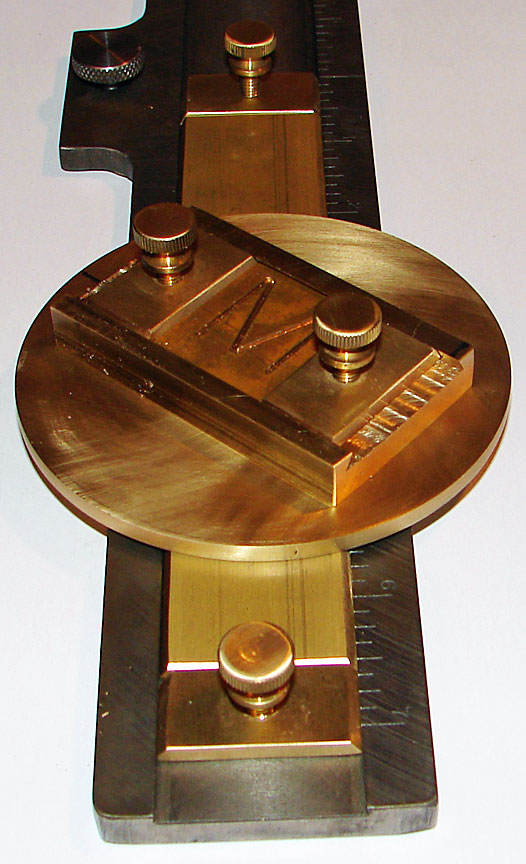

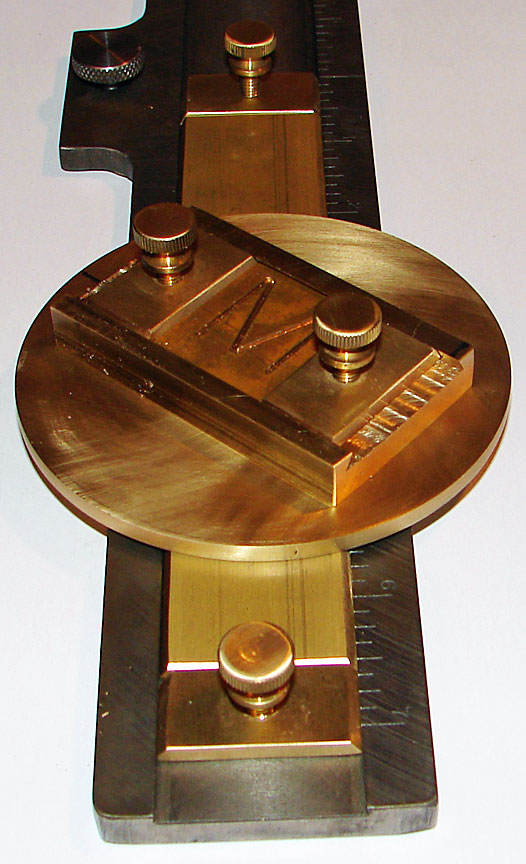

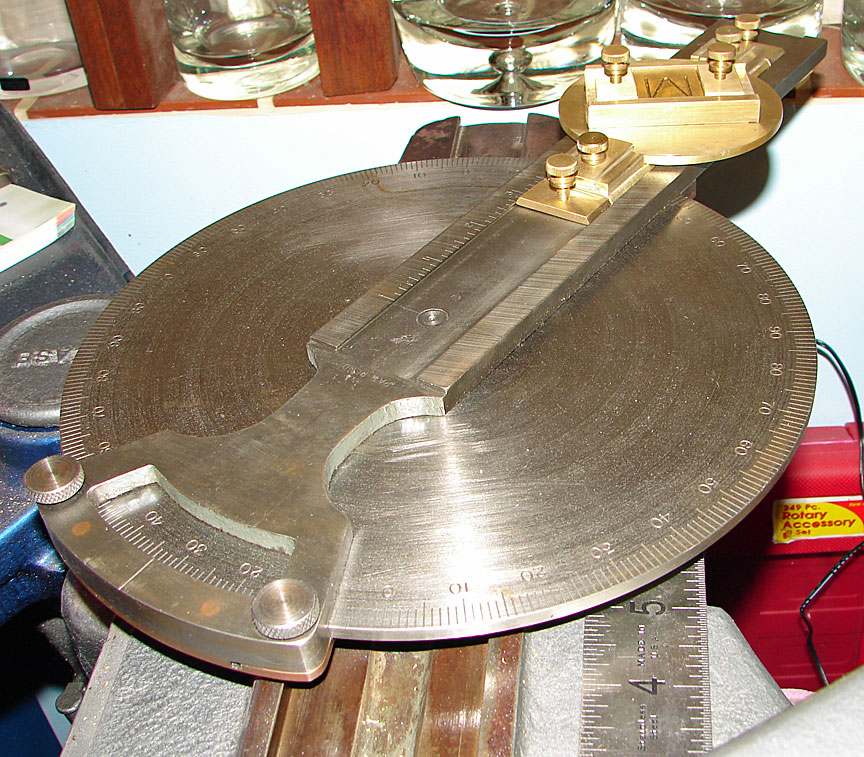

Another view ...

Another view ...

The next thing to make is a brake system to secure

this rotating mini-copyholder. A couple brake supports were cut

and then filed to the required curvature on my die filer.

The next thing to make is a brake system to secure

this rotating mini-copyholder. A couple brake supports were cut

and then filed to the required curvature on my die filer.

A slot for the brake pads was milled in both brake

supports. One of the brass brake pads is shown at the left and

the slots being milled on the right. The slots are milled to just

barely allow the brake pad to slide back and forth.

A slot for the brake pads was milled in both brake

supports. One of the brass brake pads is shown at the left and

the slots being milled on the right. The slots are milled to just

barely allow the brake pad to slide back and forth.

Below are the two brake pads slid into the brake supports

for a test fit. The brake pads were machined to be the same widths.

Below are the two brake pads slid into the brake supports

for a test fit. The brake pads were machined to be the same widths.

Here is a close up of the left brake support with its

curved end and brake pad in the slot.

Here is a close up of the left brake support with its

curved end and brake pad in the slot.

The right side also has a brake assembly.

The right side also has a brake assembly.

Here is what things look like before adding the tightening

thumb screws.

Here is what things look like before adding the tightening

thumb screws.

The completed attachment is shown below. Thumb screws

now tighten the brakes securing the rotating disc in any position.

The completed attachment is shown below. Thumb screws

now tighten the brakes securing the rotating disc in any position.

The rotating mini-copyholder with its type can now

be used for engraving.

The rotating mini-copyholder with its type can now

be used for engraving.

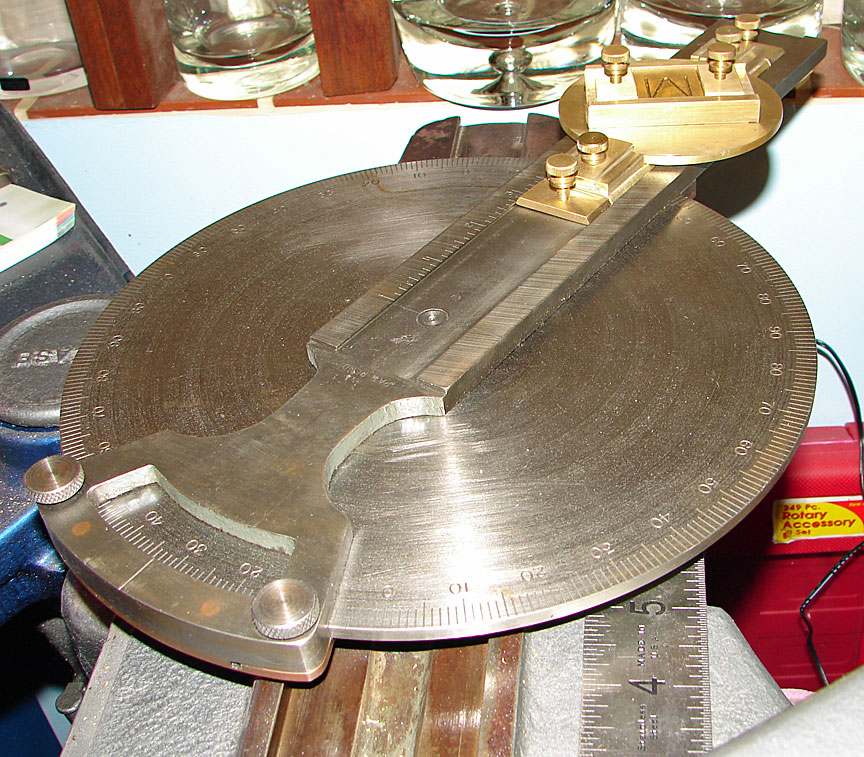

Below the completed attachment is shown installed on

the dial engraving accessory. If you can not visualize how this

could be utilized, perhaps you need to stick to engraving trophys.

Note that this new little accessory may be used with standard

1 1/4" type holders.

Below the completed attachment is shown installed on

the dial engraving accessory. If you can not visualize how this

could be utilized, perhaps you need to stick to engraving trophys.

Note that this new little accessory may be used with standard

1 1/4" type holders.

And below is a close up photo.

And below is a close up photo.

Everything is now ready for the tasks at hand.

Click here to see how I use

the master type strips.

Click here to return to the

previous page.

Click here to see

info on my Preis Panto-Grinder

Click here to go to my Gorton

265 grinder page.

Everything is now ready for the tasks at hand.

Click here to see how I use

the master type strips.

Click here to return to the

previous page.

Click here to see

info on my Preis Panto-Grinder

Click here to go to my Gorton

265 grinder page.